Cross-stitch is a form of sewing and a popular form of counted-thread embroidery in which X-shaped stitches in a tiled, raster-like pattern are used to form a picture. The stitcher counts the threads on a piece of evenweave fabric in each direction so that the stitches are of uniform size and appearance. This form of cross-stitch is also called counted cross-stitch in order to distinguish it from other forms of cross-stitch. Sometimes cross-stitch is done on designs printed on the fabric ; the stitcher simply stitches over the printed pattern. Cross-stitch is often executed on easily countable fabric called aida cloth whose weave creates a plainly visible grid of squares with holes for the needle at each corner.

The fuselage is an aircraft's main body section. It holds crew, passengers, or cargo. In single-engine aircraft, it will usually contain an engine as well, although in some amphibious aircraft the single engine is mounted on a pylon attached to the fuselage, which in turn is used as a floating hull. The fuselage also serves to position the control and stabilization surfaces in specific relationships to lifting surfaces, which is required for aircraft stability and maneuverability.

The mechanical structure of an aircraft is known as the airframe. This structure is typically considered to include the fuselage, undercarriage, empennage and wings, and excludes the propulsion system.

Kapton is a polyimide film used in flexible printed circuits and space blankets, which are used on spacecraft, satellites, and various space instruments. Invented by the DuPont Corporation in the 1960s, Kapton remains stable across a wide range of temperatures, from 4 to 673 K. Kapton is used in electronics manufacturing, space applications, with x-ray equipment, and in 3D printing applications. Its favorable thermal properties and outgassing characteristics result in its regular use in cryogenic applications and in situations where high vacuum environments are experienced.

Homebuilt aircraft, also known as amateur-built aircraft or kit planes, are constructed by persons for whom this is not a professional activity. These aircraft may be constructed from "scratch", from plans, or from assembly kits.

Homebuilt machines are machines built outside of specialised workshops or factories. This can include different things such as kit cars or homebuilt computers, but normally it pertains to homebuilt aircraft, also known as amateur-built aircraft or kit planes. Homebuilt aircraft or kit cars are constructed by amateurs. Homebuilt computers have been built at home for a long time, starting with the Victorian era pioneer Charles Babbage in the 1820s. A century later, Konrad Zuse built his own machine when electromechanical relay technology was widely available. The hobby took off with the early development of microprocessors and, since then, many enthusiasts have constructed their own computers. A homebuilt vehicle is a wider concept than a kit car. A homebuilt vehicle is a motor vehicle built by an individual instead of a manufacturer. These machines may be constructed "from scratch", from plans, or from assembly kits. Outside of the United States people wishing to build such complex machinery often have no professional networks to rely on for spare parts, plans, or advice in the matter and therefore have to rely on their ingenuity and intuition in order to build a machine that works.

The Pietenpol Air Camper is a simple parasol wing homebuilt aircraft designed by Bernard H. Pietenpol. The first prototype that became the Air Camper was built and flown by Pietenpol in 1928.

In a fixed-wing aircraft, the spar is often the main structural member of the wing, running spanwise at right angles to the fuselage. The spar carries flight loads and the weight of the wings while on the ground. Other structural and forming members such as ribs may be attached to the spar or spars, with stressed skin construction also sharing the loads where it is used. There may be more than one spar in a wing or none at all. Where a single spar carries most of the force, it is known as the main spar.

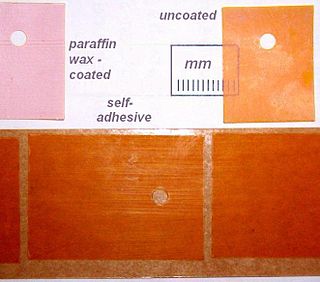

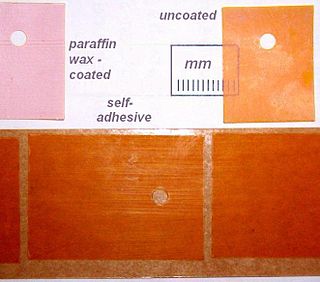

Aircraft dope is a plasticised lacquer that is applied to fabric-covered aircraft. It tightens and stiffens fabric stretched over airframes, which renders them airtight and weatherproof, increasing their durability and lifespan. The technique has been commonly applied to both full-size and flying models of aircraft.

The Wittman W-8 Tailwind is a popular two-seat light aircraft for homebuilding. It is a high-wing, braced cabin monoplane of taildragger configuration. It is constructed with a steel tubing fuselage, wood wings, and fabric covering. It offers exceptional cruising speeds and is economical to operate and maintain.

Madapollam is a soft cotton fabric manufactured from fine yarns with a dense pick laid out in linen weave. Madapollam is used as an embroidery and handkerchief fabric and as a base for fabric printing. The equal warp and weft mean that the tensile strength and shrinkage is the same in any two directions at right angles and that the fabric absorbs liquids such as ink, paint and aircraft dope equally along its X and Y axes.

The Oldfield Baby Great Lakes is a homebuilt sport biplane. The aircraft has many known names, including the Baby Lakes, Oldfield Baby Lakes, Baby Great Lakes, Super Baby Lakes, Super Baby Great Lakes, and Buddy Baby Lakes

The Howland H-3 Pegasus is an American ultralight aircraft that was designed by Bert Howland and made available by Howland Aero Design in the form of plans for amateur construction, with kits provided by Aircraft Spruce & Specialty Co. The H-3 first flew in 1988.

The Howland H-2 Honey Bee is an American homebuilt aircraft that was designed by Bert Howland and made available by Howland Aero Design in the form of plans for amateur construction, with kits provided by Aircraft Spruce & Specialty Co. The H-2 first flew in 1986.

Tube-and-fabric construction is a method of building airframes, which include the fuselages and wings of airplanes. It consists of making a framework of metal tubes and then covering the framework with an aircraft fabric covering.

The Stolp SA-500 Starlet is an American amateur-built aircraft. The aircraft is supplied in the form of plans for amateur construction by Aircraft Spruce & Specialty of Corona, California.

The Christavia Mk I is a Canadian two-seats in tandem homebuilt aircraft designed by Ron Mason. The aircraft is supplied in the form of plans for amateur construction. Designed for missionary flying in Africa, the aircraft's name means "Christ-in-Aviation". The Christavia Mk II is a side-by-side configuration version.

The Christavia Mk IV (Christ-in-Aviation) is a Canadian homebuilt aircraft that was designed by Ron Mason and produced by Elmwood Aviation of Frankford, Ontario. The aircraft is supplied in the form of plans for amateur construction.

The Kelly-D is an American homebuilt aircraft that was designed by Dudley R. Kelly of Versailles, Kentucky, in 1981. When it was available, the aircraft was supplied in the form of plans for amateur construction. Aircraft Spruce & Specialty Co still provides some spruce wing parts for the design.

Raymond M. Stits was an American inventor, homebuilt aircraft designer, aircraft mechanic and pilot. He designed the Stits SA-2A Sky Baby, which was the world's smallest aircraft in 1952, developed the Poly-Fiber aircraft fabric covering system and was the founder of Experimental Aircraft Association Chapter 1.