A locomotive or engine is a rail transport vehicle that provides the motive power for a train. If a locomotive is capable of carrying a payload, it is usually rather referred to as a multiple unit, motor coach, railcar or power car; the use of these self-propelled vehicles is increasingly common for passenger trains, but rare for freight trains.

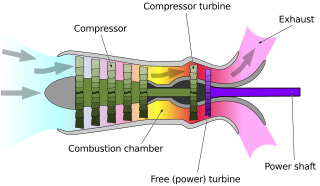

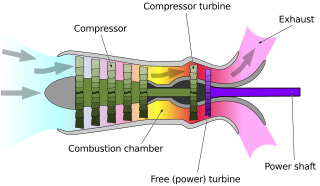

A gas turbine,gas turbine engine, or also known by its old name internal combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part and are, in the direction of flow:

An aircraft engine, often referred to as an aero engine, is the power component of an aircraft propulsion system. Aircraft using power components are referred to as powered flight. Most aircraft engines are either piston engines or gas turbines, although a few have been rocket powered and in recent years many small UAVs have used electric motors.

A diesel locomotive is a type of railway locomotive in which the power source is a diesel engine. Several types of diesel locomotives have been developed, differing mainly in the means by which mechanical power is conveyed to the driving wheels. The most common are diesel-electric locomotives and diesel-hydraulic.

The Brayton cycle is a thermodynamic cycle that describes the operation of certain heat engines that have air or some other gas as their working fluid. The original Brayton Ready Motor used a piston compressor and piston expander, but modern gas turbine engines and airbreathing jet engines also follow the Brayton cycle. Although the cycle is usually run as an open system, it is conventionally assumed for the purposes of thermodynamic analysis that the exhaust gases are reused in the intake, enabling analysis as a closed system.

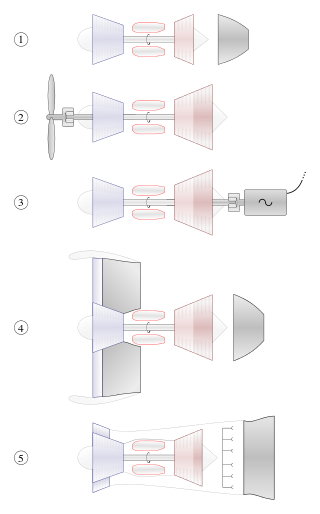

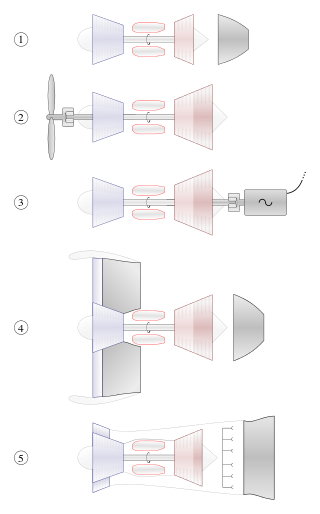

A turboshaft engine is a form of gas turbine that is optimized to produce shaft horsepower rather than jet thrust. In concept, turboshaft engines are very similar to turbojets, with additional turbine expansion to extract heat energy from the exhaust and convert it into output shaft power. They are even more similar to turboprops, with only minor differences, and a single engine is often sold in both forms.

GT3 was a prototype mainline gas turbine locomotive built in 1961 by English Electric at its Vulcan Foundry in Newton-le-Willows to investigate the use of its gas turbines in rail traction applications. It followed 18000 and 18100 as gas turbines 1 and 2. It was designed by English Electric engineer J. O. P. Hughes in a project that started in the early 1950s. Externally it resembled a steam tender locomotive, but the tender carried kerosene fuel. The designer said the traditional chassis and mechanical transmission avoided complications with relatively untried technologies for bogies and electrical transmission.

Class 80 was the TOPS classification allocated by British Rail to the prototype 25 kV AC electric locomotive. This locomotive was built by Metropolitan-Vickers, initially as a prototype gas turbine-electric locomotive, numbered 18100. British Rail allocated the number E1000 to the locomotive following its conversion from gas turbine propulsion.

Crossley, based in Manchester, United Kingdom, was a pioneering company in the production of internal combustion engines. Since 1988, it has been part of the Rolls-Royce Power Engineering group.

A gas turbine locomotive is a type of railway locomotive in which the prime mover is a gas turbine. Several types of gas turbine locomotive have been developed, differing mainly in the means by which mechanical power is conveyed to the driving wheels (drivers). A gas turbine train typically consists of two power cars, and one or more intermediate passenger cars.

British Rail 18100 was a prototype main line gas turbine-electric locomotive built for British Railways in 1951 by Metropolitan-Vickers, Manchester. It had, however, been ordered by the Great Western Railway in the 1940s, but construction was delayed due to World War II. It spent its working life on the Western Region of British Railways, operating express passenger services from Paddington station, London.

The BMW GT 101 was a turboshaft-type gas turbine engine developed from the BMW 003 aviation engine, that was considered for installation in Nazi Germany's Panther tank. The German Army's development division, the Heereswaffenamt, studied a number of gas turbine engines for use in tanks starting in mid-1944. Although none of these was fitted operationally, the GT 101 reached a production quality stage of development. Several designs were produced over the lifetime of the program, including the GT 102 and GT 103.

The Union Pacific GTELs were a series of gas turbine-electric locomotives built by Alco-GE and General Electric between 1952-1961 and operated by Union Pacific from 1952 to 1970.

Am 4/6 1101 was the world's first gas turbine-electric locomotive. The locomotive was ordered by the Swiss Federal Railways (SBB-CFF-FFS) from the Swiss Locomotive and Machine Works (SLM) and Brown, Boveri & Cie (BBC) in 1939. The locomotive was delivered in 1941 and was in use on railroads in Switzerland, France and Germany until 1954.

Advanced steam technology reflects an approach to the technical development of the steam engine intended for a wider variety of applications than has recently been the case. Particular attention has been given to endemic problems that led to the demise of steam power in small- to medium-scale commercial applications: excessive pollution, maintenance costs, labour-intensive operation, low power/weight ratio, and low overall thermal efficiency; where steam power has generally now been superseded by the internal combustion engine or by electrical power drawn from an electrical grid. The only steam installations that are in widespread use are the highly efficient thermal power plants used for generating electricity on a large scale. In contrast, the proposed steam engines may be for stationary, road, rail or marine use.

Bowesfield Works was a railway locomotive manufacturing plant in Stockton-on-Tees. The works was operated by a joint venture company called Metropolitan Vickers-Beyer Peacock from 1949 until 1960.

An internal combustion engine is a heat engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons, turbine blades, a rotor, or a nozzle. This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to.

A turbine–electric transmission system includes a turboshaft gas turbine connected to an electrical generator, creating electricity that powers electric traction motors. No clutch is required.

The South African Railways gas-electric locomotive of 1923 was an experimental gas-electric locomotive. The fuel, suction gas, was generated on-board the locomotive from coal.

An internal combustion locomotive is a type of railway locomotive that produces its pulling power using an internal combustion engine. These locomotives are fuelled by burning fossil fuels, most commonly oil or gasoline, to produce rotational power which is transmitted to the locomotive's driving wheels by various direct or indirect transmission mechanisms. The fuel is carried on the locomotive.