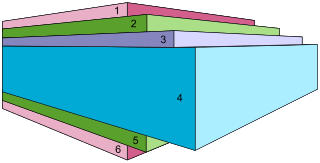

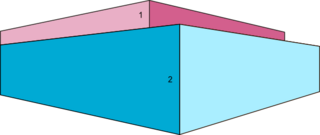

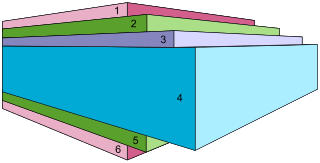

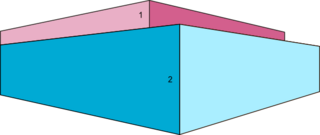

Corrugated fiberboard, corrugated cardboard, or corrugated is a type of packaging material consisting of a fluted corrugated sheet and one or two flat linerboards. It is made on "flute lamination machines" or "corrugators" and is used for making corrugated boxes. The corrugated medium sheet and the linerboard(s) are made of kraft containerboard, a paperboard material usually over 0.25 millimetres (0.01 in) thick.

Pulp is a fibrous lignocellulosic material prepared by chemically, semi-chemically or mechanically producing cellulosic fibers from wood, fiber crops, waste paper, or rags. Mixed with water and other chemicals or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other paper products.

Paperboard is a thick paper-based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker than paper and has certain superior attributes such as foldability and rigidity. According to ISO standards, paperboard is a paper with a grammage above 250 g/m2, but there are exceptions. Paperboard can be single- or multi-ply.

Pulpwood can be defined as timber that is ground and processed into a fibrous pulp. It is a versatile natural resource commonly used for paper-making but also made into low-grade wood and used for chips, energy, pellets, and engineered products.

Holmen AB is a Swedish company which bases its business in the forest industry and the pulp and paper industry. Holmen's main products are paperboard for consumer packaging and graphical applications. Printing paper for magazines, supplements, direct mail, directories, books and newspapers. Holmen also produce sawn timber for flooring, window components, furniture or construction.

Cascades Inc. is a Canadian company that produces, converts, and markets packaging and tissue products composed mainly of recycled fibres. Cascades employs around 10,000 people in more than 70 operating units in North America. It was founded in 1964.

Kraft paper or kraft is paper or paperboard (cardboard) produced from chemical pulp produced in the kraft process.

The folding carton created the packaging industry as it is known today, beginning in the late 19th century. The process involves folding carton made of paperboard that is printed, laminated, cut, then folded and glued. The cartons are shipped flat to a packager, which has its own machinery to fold the carton into its final shape as a container for a product. Some styles of folding cartons can be made of E-flute or micro-flute corrugated fiberboard.

Cardboard is a generic term for a heavy-duty paper.

Paper is a thin sheet material produced by mechanically or chemically processing cellulose fibres derived from wood, rags, grasses, herbivore dung, or other vegetable sources in water. Once the water is drained through a fine mesh leaving the fibre evenly distributed on the surface, it can be pressed and dried.

Deinking is the industrial process of removing printing ink from paperfibers of recycled paper to make deinked pulp.

Holmen Iggesund is a premium paperboard company, part of the Holmen Group. Holmen is one of the largest forest owners in Sweden which bases its business in the forest industry and the pulp and paper industry. Holmen's main products are paperboard for consumer packaging and graphical applications, printing paper for magazines, direct mail, books and newspapers.

Liquid packaging board is a multi-ply paperboard with high stiffness, strong wet sizing and a high barrier coating, e.g. plastic. Only virgin paper fibers are used. The barrier coating must hold the liquid and prevent migration of air and flavors through the paperboard.

The environmental impact of paper are significant, which has led to changes in industry and behaviour at both business and personal levels. With the use of modern technology such as the printing press and the highly mechanized harvesting of wood, disposable paper became a relatively cheap commodity, which led to a high level of consumption and waste. The rise in global environmental issues such as air and water pollution, climate change, overflowing landfills and clearcutting have all lead to increased government regulations. There is now a trend towards sustainability in the pulp and paper industry as it moves to reduce clear cutting, water use, greenhouse gas emissions, fossil fuel consumption and clean up its influence on local water supplies and air pollution.

White-lined chipboard is a grade of paperboard typically made from layers of waste paper or recycled fibers. Most often it comes with two to three layers of coating on the top and one layer on the reverse side. Because of its recycled content it will be grey from the inside. The main end use for this type of board is for packaging of frozen or chilled food, cereals, shoes, toys and others.

Solid bleached board (SBB) or solid bleached sulphate (SBS) is a virgin fibre grade of paperboard.

Solid unbleached board, also known as SUB, is a grade of paperboard typically made of unbleached chemical pulp. Most often it comes with two to three layers of mineral or synthetic pigment coating on the top and one layer on the reverse side. Recycled fibres are sometimes used to replace the unbleached chemical pulp.

Clearwater Paper Corporation is an American pulp and paperboard manufacturer. The company was created on December 9, 2008, via a spin-off from Potlatch Corporation and is headquartered in Spokane, Washington.

Cardboard is a generic term for heavy paper-based products. The construction can range from a thick paper known as paperboard to corrugated fiberboard which is made of multiple plies of material. Natural cardboards can range from grey to light brown in color, depending on the specific product; dyes, pigments, printing, and coatings are available.

Mechanical pulping is the process in which wood is separated or defibrated mechanically into pulp for the paper industry.