Pottery is the process and the products of forming vessels and other objects with clay and other raw materials, which are fired at high temperatures to give them a hard and durable form. The place where such wares are made by a potter is also called a pottery. The definition of pottery, used by the ASTM International, is "all fired ceramic wares that contain clay when formed, except technical, structural, and refractory products". End applications include tableware, decorative ware, sanitary ware, and in technology and industry such as electrical insulators and laboratory ware. In art history and archaeology, especially of ancient and prehistoric periods, pottery often means vessels only, and sculpted figurines of the same material are called terracottas.

Porcelain is a ceramic material made by heating raw materials, generally including kaolinite, in a kiln to temperatures between 1,200 and 1,400 °C. The greater strength and translucence of porcelain, relative to other types of pottery, arise mainly from vitrification and the formation of the mineral mullite within the body at these high temperatures. End applications include tableware, decorative ware such as figurines, toilets and washbasins, and products in technology and industry such as electrical insulators and laboratory ware.

Earthenware is glazed or unglazed nonvitreous pottery that has normally been fired below 1,200 °C (2,190 °F). Basic earthenware, often called terracotta, absorbs liquids such as water. However, earthenware can be made impervious to liquids by coating it with a ceramic glaze, and such a process is used for the great majority of modern domestic earthenware. The main other important types of pottery are porcelain, bone china, and stoneware, all fired at high enough temperatures to vitrify. End applications include tableware and decorative ware such as figurines.

Faience or faïence is the general English language term for fine tin-glazed pottery. The invention of a white pottery glaze suitable for painted decoration, by the addition of an oxide of tin to the slip of a lead glaze, was a major advance in the history of pottery. The invention seems to have been made in Iran or the Middle East before the ninth century. A kiln capable of producing temperatures exceeding 1,000 °C (1,830 °F) was required to achieve this result, the result of millennia of refined pottery-making traditions. The term is now used for a wide variety of pottery from several parts of the world, including many types of European painted wares, often produced as cheaper versions of porcelain styles.

Stoneware is a broad term for pottery fired at a relatively high temperature. A modern definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. End applications include tableware, decorative ware such as vases.

Denby Pottery Company Ltd is a British manufacturer of pottery, named after the village of Denby in Derbyshire where it is based. It primarily sells hand-crafted stoneware tableware, kitchenware and serveware products including dinner sets, mugs and serving dishes, as well as a variety of glassware products and cast-iron cookware.

The Staffordshire Potteries is the industrial area encompassing the six towns Burslem, Fenton, Hanley, Longton, Stoke and Tunstall, which is now the city of Stoke-on-Trent in Staffordshire, England. North Staffordshire became a centre of ceramic production in the early 17th century, due to the local availability of clay, salt, lead and coal.

Salt-glaze or salt glaze pottery is pottery, usually stoneware, with a ceramic glaze of glossy, translucent and slightly orange-peel-like texture which was formed by throwing common salt into the kiln during the higher temperature part of the firing process. Sodium from the salt reacts with silica in the clay body to form a glassy coating of sodium silicate. The glaze may be colourless or may be coloured various shades of brown, blue, or purple.

Biscuit porcelain, bisque porcelain or bisque is unglazed, white porcelain treated as a final product, with a matte appearance and texture to the touch. It has been widely used in European pottery, mainly for sculptural and decorative objects that are not tableware and so do not need a glaze for protection.

Wedgwood is an English fine china, porcelain and luxury accessories manufacturer that was founded on 1 May 1759 by the potter and entrepreneur Josiah Wedgwood and was first incorporated in 1895 as Josiah Wedgwood and Sons Ltd. It was rapidly successful and was soon one of the largest manufacturers of Staffordshire pottery, "a firm that has done more to spread the knowledge and enhance the reputation of British ceramic art than any other manufacturer", exporting across Europe as far as Russia, and to the Americas. It was especially successful at producing fine earthenware and stoneware that were accepted as equivalent in quality to porcelain but were considerably cheaper.

Mintons was a major company in Staffordshire pottery, "Europe's leading ceramic factory during the Victorian era", an independent business from 1793 to 1968. It was a leader in ceramic design, working in a number of different ceramic bodies, decorative techniques, and "a glorious pot-pourri of styles - Rococo shapes with Oriental motifs, Classical shapes with Medieval designs and Art Nouveau borders were among the many wonderful concoctions". As well as pottery vessels and sculptures, the firm was a leading manufacturer of tiles and other architectural ceramics, producing work for both the Houses of Parliament and United States Capitol.

Sprigging or sprigged decoration is a technique for decorating pottery with low relief shapes made separately from the main body and applied to it before firing. Usually thin press moulded shapes are applied to greenware or bisque. The resulting pottery is termed sprigged ware, and the added piece is a "sprig". The technique may also be described by terms such as "applied relief decoration", especially in non-European pottery.

Agnete Hoy, also known as Anita Hoy, was an English artist potter who managed successfully to create a bridge between industrial ceramics and work of the studio potters. Having studied in Copenhagen she went on to work for the Holbæk and Saxbo potteries in the late-1930s before returning to England. Agnete's Danish experience helped her creativity within the English ceramic industry during the war years and the following period.

John Doulton was an English businessman and manufacturer of pottery, a founder of the firm that later became known as Royal Doulton. John Doulton married Jane Duneau, a widow from Bridgnorth in Shropshire, who died on 9 April 1841. They had eight children, including Sir Henry, MP Frederick, Josiah and Alfred.

Art pottery is a term for pottery with artistic aspirations, made in relatively small quantities, mostly between about 1870 and 1930. Typically, sets of the usual tableware items are excluded from the term; instead the objects produced are mostly decorative vessels such as vases, jugs, bowls and the like which are sold singly. The term originated in the later 19th century, and is usually used only for pottery produced from that period onwards. It tends to be used for ceramics produced in factory conditions, but in relatively small quantities, using skilled workers, with at the least close supervision by a designer or some sort of artistic director. Studio pottery is a step up, supposed to be produced in even smaller quantities, with the hands-on participation of an artist-potter, who often performs all or most of the production stages. But the use of both terms can be elastic. Ceramic art is often a much wider term, covering all pottery that comes within the scope of art history, but "ceramic artist" is often used for hands-on artist potters in studio pottery.

Franciscan Ceramics are ceramic tableware and tile products produced by Gladding, McBean & Co. in Los Angeles, California, US from 1934 to 1962, International Pipe and Ceramics (Interpace) from 1962 to 1979, and Wedgwood from 1979 to 1983. Wedgwood closed the Los Angeles plant, and moved the production of dinnerware to England in 1983. Waterford Glass Group plc purchased Wedgwood in 1986, becoming Waterford Wedgwood. KPS Capital Partners acquired all of the holdings of Waterford Wedgwood in 2009. The Franciscan brand became part of a group of companies known as WWRD, an acronym for "Wedgwood Waterford Royal Doulton." WWRD continues to produce the Franciscan patterns Desert Rose and Apple.

California pottery includes industrial, commercial, and decorative pottery produced in the Northern California and Southern California regions of the U.S. state of California. Production includes brick, sewer pipe, architectural terra cotta, tile, garden ware, tableware, kitchenware, art ware, figurines, giftware, and ceramics for industrial use. Ceramics include terra cotta, earthenware, porcelain, and stoneware products.

The Fulham Pottery was founded in Fulham, London, by John Dwight in 1672, at the junction of New King's Road and Burlington Road, Fulham, not far from Putney Bridge. Dwight is the earliest clearly documented maker of stoneware in England, although immigrant Dutch or German potters were probably active several decades before. By 1690 there was a rival stoneware operation in Fulham, run by the Dutch Elers brothers, who after a few years went off to become important early figures in transforming the Staffordshire pottery industry.

The Ridgway family was one of the important dynasties manufacturing Staffordshire pottery, with a large number of family members and business names, over a period from the 1790s to the late 20th century. In their heyday in the mid-19th century there were several different potteries run by different branches of the family. Most of their wares were earthenware, but often of very high quality, but stoneware and bone china were also made. Many earlier pieces were unmarked and identifying them is difficult or impossible. Typically for Staffordshire, the various businesses, initially set up as partnerships, changed their official names rather frequently, and often used different trading names, so there are a variety of names that can be found.

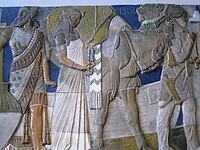

Ceramic art is art made from ceramic materials, including clay. It may take varied forms, including artistic pottery, including tableware, tiles, figurines and other sculpture. As one of the plastic arts, ceramic art is a visual art. While some ceramics are considered fine art, such as pottery or sculpture, most are considered to be decorative, industrial or applied art objects. Ceramic art can be created by one person or by a group, in a pottery or a ceramic factory with a group designing and manufacturing the artware.