Related Research Articles

An electrode is an electrical conductor used to make contact with a nonmetallic part of a circuit. Electrodes are essential parts of batteries that can consist of a variety of materials (chemicals) depending on the type of battery.

In chemistry and manufacturing, electrolysis is a technique that uses direct electric current (DC) to drive an otherwise non-spontaneous chemical reaction. Electrolysis is commercially important as a stage in the separation of elements from naturally occurring sources such as ores using an electrolytic cell. The voltage that is needed for electrolysis to occur is called the decomposition potential. The word "lysis" means to separate or break, so in terms, electrolysis would mean "breakdown via electricity."

Electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current. The part to be coated acts as the cathode of an electrolytic cell; the electrolyte is a solution of a salt whose cation is the metal to be coated, and the anode is usually either a block of that metal, or of some inert conductive material. The current is provided by an external power supply.

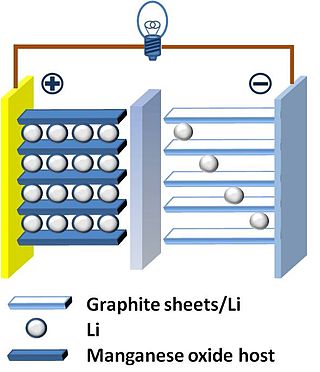

A lithium-ion or Li-ion battery is a type of rechargeable battery that uses the reversible intercalation of Li+ ions into electronically conducting solids to store energy. In comparison with other commercial rechargeable batteries, Li-ion batteries are characterized by higher specific energy, higher energy density, higher energy efficiency, a longer cycle life, and a longer calendar life. Also noteworthy is a dramatic improvement in lithium-ion battery properties after their market introduction in 1991: over the following 30 years, their volumetric energy density increased threefold while their cost dropped tenfold.

Nanobatteries are fabricated batteries employing technology at the nanoscale, particles that measure less than 100 nanometers or 10−7 meters. These batteries may be nano in size or may use nanotechnology in a macro scale battery. Nanoscale batteries can be combined to function as a macrobattery such as within a nanopore battery.

Nanodot can refer to several technologies which use nanometer-scale localized structures. Nanodots generally exploit properties of quantum dots to localize magnetic or electrical fields at very small scales. Applications for nanodots could include high-density information storage, energy storage, and light-emitting devices.

A nanowire battery uses nanowires to increase the surface area of one or both of its electrodes, which improves the capacity of the battery. Some designs, variations of the lithium-ion battery have been announced, although none are commercially available. All of the concepts replace the traditional graphite anode and could improve battery performance. Each type of nanowire battery has specific advantages and disadvantages, but a challenge common to all of them is their fragility.

A lithium-ion capacitor is a hybrid type of capacitor classified as a type of supercapacitor. It is called a hybrid because the anode is the same as those used in lithium-ion batteries and the cathode is the same as those used in supercapacitors. Activated carbon is typically used as the cathode. The anode of the LIC consists of carbon material which is often pre-doped with lithium ions. This pre-doping process lowers the potential of the anode and allows a relatively high output voltage compared to other supercapacitors.

The lithium–sulfur battery is a type of rechargeable battery. It is notable for its high specific energy. The low atomic weight of lithium and moderate atomic weight of sulfur means that Li–S batteries are relatively light. They were used on the longest and highest-altitude unmanned solar-powered aeroplane flight by Zephyr 6 in August 2008.

The thin-film lithium-ion battery is a form of solid-state battery. Its development is motivated by the prospect of combining the advantages of solid-state batteries with the advantages of thin-film manufacturing processes.

A solid-state battery is an electrical battery that uses a solid electrolyte for ionic conductions between the electrodes, instead of the liquid or gel polymer electrolytes found in conventional batteries. Solid-state batteries theoretically offer much higher energy density than the typical lithium-ion or lithium polymer batteries.

Nanoarchitectures for lithium-ion batteries are attempts to employ nanotechnology to improve the design of lithium-ion batteries. Research in lithium-ion batteries focuses on improving energy density, power density, safety, durability and cost.

The lithium–air battery (Li–air) is a metal–air electrochemical cell or battery chemistry that uses oxidation of lithium at the anode and reduction of oxygen at the cathode to induce a current flow.

A potassium-ion battery or K-ion battery is a type of battery and analogue to lithium-ion batteries, using potassium ions for charge transfer instead of lithium ions.

Research in lithium-ion batteries has produced many proposed refinements of lithium-ion batteries. Areas of research interest have focused on improving energy density, safety, rate capability, cycle durability, flexibility, and reducing cost.

Lithium–silicon batteries are lithium-ion batteries that employ a silicon-based anode, and lithium ions as the charge carriers. Silicon based materials, generally, have a much larger specific capacity, for example, 3600 mAh/g for pristine silicon. The standard anode material graphite is limited to a maximum theoretical capacity of 372 mAh/g for the fully lithiated state LiC6.

Debra R. Rolison is a physical chemist at the Naval Research Laboratory, where she is a head of the Advanced Electrochemical Materials section. Rolison's research involves the design, synthesis, and characterization of multi-functional nanostructures and ultra porous materials for rate-critical applications such as catalysis and energy storage. She is the 112th recipient of the William H. Nichols Medal Award.

Linda Faye Nazar is a Senior Canada Research Chair in Solid State Materials and Distinguished Research Professor of Chemistry at the University of Waterloo. She develops materials for electrochemical energy storage and conversion. Nazar demonstrated that interwoven composites could be used to improve the energy density of lithium–sulphur batteries. She was awarded the 2019 Chemical Institute of Canada Medal.

Kristina Edström is a Swedish Professor of Inorganic Chemistry at Uppsala University. She also serves as Head of the Ångström Advanced Battery Centre (ÅABC) and has previously been both Vice Dean for Research at the Faculty of Science and Technology and Chair of the STandUp for Energy research programme.

Lynden A. Archer is a chemical engineer, Joseph Silbert Dean of Engineering, David Croll Director of the Energy Systems Institute, and professor of chemical engineering at Cornell University. He became a fellow of the American Physical Society in 2007 and was elected into the National Academy of Engineering in 2018. Archer's research covers polymer and hybrid materials and finds applications in energy storage technologies. His h-index is 92 by Google Scholar.

References

- 1 2 3 4 5 "Amy Prieto is building safer, more powerful batteries". Chemical & Engineering News. Retrieved 2020-03-10.

- ↑ Molella, Arthur P.; Karvellas, Anna (2015-09-15). Places of Invention. Smithsonian Institution. ISBN 978-1-935623-69-4.

- ↑ Sofge, Erik (2014-08-12). "How to Make Battery Power More Powerful". Popular Mechanics. Retrieved 2020-03-11.

- ↑ Dolcourt, Jessica. "Smartphone battery life: 2 problems, 4 fixes (Smartphones Unlocked)". CNET. Retrieved 2020-03-10.

- 1 2 Hanley, Steve (2023-05-23). "Prieto Introduces Battery That Charges In 3 Minutes". CleanTechnica. Retrieved 2023-05-25.

- ↑ "Entrepreneur rethinks lithium-ion batteries with an eye toward storing renewable energy". Chemical & Engineering News. Retrieved 2020-03-11.

- 1 2 3 Post, Tamara Chuang | The Denver (2017-06-18). "Your smartphone battery is going to get way better if Prieto can turn its 3-D battery into a commercial reality". The Denver Post. Retrieved 2020-03-11.

- ↑ Martin, Richard. "Startup Prieto Manufactures Batteries Made of 3-D Foam Structures". MIT Technology Review. Retrieved 2020-03-11.

- ↑ "President Obama Honors Early Career Scientists and Engineers". www.nsf.gov. Retrieved 2020-03-10.

- ↑ "NSF Award Search: Award#0956011 - CAREER: Energy Storage and Conversion- Coupling the Direct Electrodeposition of Crystalline Intermetallics with Targeted Outreach to Elementary Schools". www.nsf.gov. Retrieved 2020-03-10.

- ↑ "New Women in Science Fellowship Program, Honors Future Science Leaders – Press Releases on CSRwire.com". www.csrwire.com. Retrieved 2020-03-10.