A utility knife is any type of knife used for general manual work purposes. Such knives were originally fixed-blade knives with durable cutting edges suitable for rough work such as cutting cordage, cutting/scraping hides, butchering animals, cleaning fish scales, reshaping timber, and other tasks. Craft knives are small utility knives used as precision-oriented tools for finer, more delicate tasks such as carving and papercutting.

A knife is a tool or weapon with a cutting edge or blade, usually attached to a handle or hilt. One of the earliest tools used by humanity, knives appeared at least 2.5 million years ago, as evidenced by the Oldowan tools. Originally made of wood, bone, and stone, over the centuries, in step with improvements in both metallurgy and manufacturing, knife blades have been made from copper, bronze, iron, steel, ceramic, and titanium. Most modern knives have either fixed or folding blades; blade patterns and styles vary by maker and country of origin.

The router is a power tool with a flat base and a rotating blade extending past the base. The spindle may be driven by an electric motor or by a pneumatic motor. It routs an area in hard material, such as wood or plastic. Routers are used most often in woodworking, especially cabinetry. They may be handheld or affixed to router tables. Some woodworkers consider the router one of the most versatile power tools.

A nail clipper is a hand tool used to trim fingernails, toenails and hangnails.

Scissors are hand-operated shearing tools. A pair of scissors consists of a pair of metal blades pivoted so that the sharpened edges slide against each other when the handles (bows) opposite to the pivot are closed. Scissors are used for cutting various thin materials, such as paper, cardboard, metal foil, cloth, rope, and wire. A large variety of scissors and shears all exist for specialized purposes. Hair-cutting shears and kitchen shears are functionally equivalent to scissors, but the larger implements tend to be called shears. Hair-cutting shears have specific blade angles ideal for cutting hair. Using the incorrect type of scissors to cut hair will result in increased damage or split ends, or both, by breaking the hair. Kitchen shears, also known as kitchen scissors, are intended for cutting and trimming foods such as meats.

A blade is the portion of a tool, weapon, or machine with an edge that is designed to puncture, chop, slice or scrape surfaces or materials. Blades are typically made from materials that are harder than those they are to be used on. Historically, humans have made blades from flaking stones such as flint or obsidian, and from various metal such as copper, bronze and iron. Modern blades are often made of steel or ceramic. Blades are one of humanity's oldest tools, and continue to be used for combat, food preparation, and other purposes.

A string trimmer, also known by the portmanteau strimmer and the trademarks Weedwacker, Weed eater and Whipper Snipper. is a garden tool for cutting grass, small weeds, and groundcover. It uses a whirling monofilament line instead of a blade, which protrudes from a rotating spindle at the end of a long shaft topped by a gasoline engine or electric motor.

A microtome is a cutting tool used to produce extremely thin slices of material known as sections. Important in science, microtomes are used in microscopy, allowing for the preparation of samples for observation under transmitted light or electron radiation.

A kitchen knife is any knife that is intended to be used in food preparation. While much of this work can be accomplished with a few general-purpose knives – notably a large chef's knife, a tough cleaver, a small paring knife and some sort of serrated blade – there are also many specialized knives that are designed for specific tasks. Kitchen knives can be made from several different materials.

Chore division is a fair division problem in which the divided resource is undesirable, so that each participant wants to get as little as possible. It is the mirror-image of the fair cake-cutting problem, in which the divided resource is desirable so that each participant wants to get as much as possible. Both problems have heterogeneous resources, meaning that the resources are nonuniform. In cake division, cakes can have edge, corner, and middle pieces along with different amounts of frosting. Whereas in chore division, there are different chore types and different amounts of time needed to finish each chore. Similarly, both problems assume that the resources are divisible. Chores can be infinitely divisible, because the finite set of chores can be partitioned by chore or by time. For example, a load of laundry could be partitioned by the number of articles of clothing and/or by the amount of time spent loading the machine. The problems differ, however, in the desirability of the resources. The chore division problem was introduced by Martin Gardner in 1978.

X-Acto is a brand name for a variety of cutting tools and office products owned by Elmer's Products, Inc. Cutting tools include hobby and utility knives, saws, carving tools and many small-scale precision knives used for crafts and other applications.

Punching is a forming process that uses a punch press to force a tool, called a punch, through the workpiece to create a hole via shearing. Punching is applicable to a wide variety of materials that come in sheet form, including sheet metal, paper, vulcanized fibre and some forms of plastic sheet. The punch often passes through the work into a die. A scrap slug from the hole is deposited into the die in the process. Depending on the material being punched this slug may be recycled and reused or discarded.

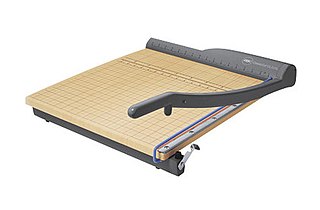

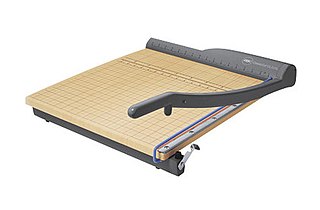

A paper cutter, also known as a paper guillotine or simply a guillotine, is a tool often found in offices and classrooms, designed to administer straight cuts to single sheets or large stacks of paper at once.

A dowel is a cylindrical rod, usually made of wood, plastic, or metal. In its original manufactured form, a dowel is called a dowel rod. Dowel rods are often cut into short lengths called dowel pins. Dowels are commonly used as structural reinforcements in cabinet making and in numerous other applications, including:

Knife sharpening is the process of making a knife or similar tool sharp by grinding against a hard, rough surface, typically a stone, or a flexible surface with hard particles, such as sandpaper. Additionally, a leather razor strop, or strop, is often used to straighten and polish an edge.

Roll slitting is a shearing operation that cuts a large roll of material into narrower rolls. There are two types of slitting: log slitting and rewind slitting. In log slitting the roll of material is treated as a whole and one or more slices are taken from it without an unrolling/re-reeling process. In rewind slitting the web is unwound and run through the machine, passing through knives or lasers, before being rewound on one or more shafts to form narrower rolls. The multiple narrower strips of material may be known as mults or pancakes if their diameter is much more than their width. For rewind slitting the machine used is called a slitter rewinder, a slitter or a slitting machine – these names are used interchangeably for the same machines. For particularly narrow and thin products, the pancakes become unstable, and then the rewind may be onto a bobbin-wound reel: the rewind bobbins are much wider than the slit width and the web oscillates across the reel as it is rewound. Apart from the stability benefit it is also then possible to put very long lengths,, onto one bobbin.

Shearing, also known as die cutting, is a process that cuts stock without the formation of chips or the use of burning or melting. Strictly speaking, if the cutting blades are straight the process is called shearing; if the cutting blades are curved then they are shearing-type operations. The most commonly sheared materials are in the form of sheet metal or plates. However, rods can also be sheared. Shearing-type operations include blanking, piercing, roll slitting, and trimming. It is used for metal, fabric, paper and plastics.

There are many types of shears used to shear or cut sheet metal.

Press tools are commonly used in hydraulic, pneumatic, and mechanical presses to produce the sheet metal components in large volumes. Generally press tools are categorized by the types of operation performed using the tool, such as blanking, piercing, bending, forming, forging, trimming etc. The press tool will also be specified as a blanking tool, piercing tool, bending tool etc.

The splitting band knife is a kind of knife used in several fields including: tannery, EVA/rubber, foam, cork, shoe and leather goods, paper, carpet and other soft sheet materials. It is a power tool which is very similar in operation to a band saw, with an endless loop blade; the material to be cut is supported by a flat table.