Beer is an alcoholic beverage produced by the brewing and fermentation of starches from cereal grain—most commonly malted barley, although wheat, maize (corn), rice, and oats are also used. The grain is mashed to convert starch in the grain to sugars, which dissolve in water to form wort. Fermentation of the wort by yeast produces ethanol and carbonation in the beer. Beer is one of the oldest alcoholic drinks in the world, the most widely consumed, and the third most popular drink after water and tea. Most modern beer is brewed with hops, which add bitterness and other flavours and act as a natural preservative and stabilising agent. Other flavouring agents, such as gruit, herbs, or fruits, may be included or used instead of hops. In commercial brewing, natural carbonation is often replaced with forced carbonation.

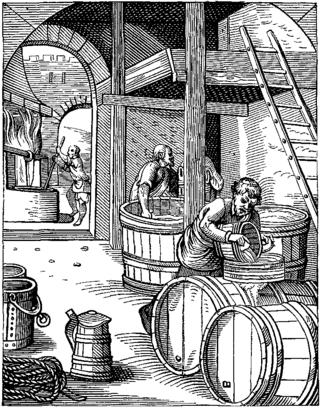

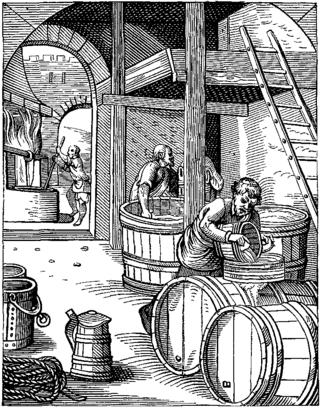

Brewing is the production of beer by steeping a starch source in water and fermenting the resulting sweet liquid with yeast. It may be done in a brewery by a commercial brewer, at home by a homebrewer, or communally. Brewing has taken place since around the 6th millennium BC, and archaeological evidence suggests that emerging civilizations, including ancient Egypt, China, and Mesopotamia, brewed beer. Since the nineteenth century the brewing industry has been part of most western economies.

Homebrewing is the brewing of beer or other alcoholic beverages on a small scale for personal, non-commercial purposes. Supplies, such as kits and fermentation tanks, can be purchased locally at specialty stores or online. Beer was brewed domestically for thousands of years before its commercial production although its legality has varied according to local regulation. Homebrewing is closely related to the hobby of home distillation, the production of alcoholic spirits for personal consumption, but home distillation is generally more tightly regulated.

Lambic is a type of beer brewed in the Pajottenland region of Belgium southwest of Brussels and in Brussels itself since the 13th century. Types of lambic beer include gueuze, kriek lambic, and framboise. Lambic differs from most other beers in that it is fermented through exposure to wild yeasts and bacteria native to the Zenne valley, as opposed to exposure to carefully cultivated strains of brewer's yeast. This process gives the beer its distinctive flavour: dry, vinous, and cidery, often with a tart aftertaste.

India pale ale (IPA) is a hoppy beer style within the broader category of pale ale.

Brettanomyces is a non-spore forming genus of yeast in the family Saccharomycetaceae, and is often colloquially referred to as "Brett". The genus name Dekkera is used interchangeably with Brettanomyces, as it describes the teleomorph or spore forming form of the yeast, but is considered deprecated under the one fungus, one name change. The cellular morphology of the yeast can vary from ovoid to long "sausage" shaped cells. The yeast is acidogenic, and when grown on glucose rich media under aerobic conditions, produces large amounts of acetic acid. Brettanomyces is important to both the brewing and wine industries due to the sensory compounds it produces.

Wychwood Brewery was a brewery and pub chain based in Witney, Oxfordshire, England. the brand is currently owned owned by Carlsberg Marston's. Hobgoblin, a 5.2% abv brown ale, was the company's flagship brand.

Gose is a warm fermented beer that is usually brewed with at least 50% of the grain bill being malted wheat, fruit syrups- such as lemon, coriander- and salt - either added or a component of the water used. It acquires its characteristic sourness through inoculation with Lactobacillus bacteria, which is not a hop-tolerant bacteria and which provides only a light acidity. Unlike some beers, such as India pale ales, gose beers typically do not have prominent hop bitterness, flavours, or aroma and have a relatively low alcohol content of 4 to 5% alcohol by volume.

Beer has been brewed in England for thousands of years. As a beer brewing country, it is known for top fermented cask beer which finishes maturing in the cellar of the pub rather than at the brewery and is served with only natural carbonation.

In brewing, adjuncts are unmalted grains or grain products used in brewing beer which supplement the main mash ingredient. This is often done with the intention of cutting costs, but sometimes also to create an additional feature, such as better foam retention, flavours or nutritional value or additives. Both solid and liquid adjuncts are commonly used.

W. H. Brakspear & Sons Ltd. was a brewery in Henley-on-Thames, Oxfordshire, England. Since the closure of the brewery in 2002, its beers have been brewed by Wychwood Brewery in West Oxfordshire. In 1993, beer writer Michael Jackson described its "ordinary" bitter as the best in England.

Allagash Brewing Company is a brewery in Portland, Maine. The brewery specializes in Belgian style beers.

Beer styles differentiate and categorise beers by colour, flavour, strength, ingredients, production method, recipe, history, or origin.

Beer is one of the oldest human-produced drinks. The written history of ancient Egypt and Mesopotamia records the use of beer, and the drink has spread throughout the world; a 3,900-year-old Sumerian poem honouring Ninkasi, the patron goddess of brewing, contains the oldest surviving beer-recipe, describing the production of beer from barley bread, and in China, residue on pottery dating from around 5,000 years ago shows that beer was brewed using barley and other grains.

A brewery or brewing company is a business that makes and sells beer. The place at which beer is commercially made is either called a brewery or a beerhouse, where distinct sets of brewing equipment are called plant. The commercial brewing of beer has taken place since at least 2500 BC; in ancient Mesopotamia, brewers derived social sanction and divine protection from the goddess Ninkasi. Brewing was initially a cottage industry, with production taking place at home; by the ninth century, monasteries and farms would produce beer on a larger scale, selling the excess; and by the eleventh and twelfth centuries larger, dedicated breweries with eight to ten workers were being built.

Beer is often made from barley malt, water, hops and yeast and so is often suitable for vegans and vegetarians. Some beer brewers add finings to clarify the beer when racking into a barrel. Finings can include plant-derived products, like Irish moss, or animal-derived products, like isinglass and gelatin.

The principal factors that characterize beer are bitterness, the variety of flavours present in the beverage and their intensity, alcohol content, and colour. Standards for those characteristics allow a more objective and uniform determination to be made on the overall qualities of any beer.

Sour beer is beer which has an intentionally acidic, tart, or sour taste. Sour beer styles include Belgian lambics and Flanders red ale and German Gose and Berliner Weisse.

Porter is a style of beer that was developed in London in the early 18th century. It is well-hopped and dark in appearance owing to the use of brown malt. The name is believed to have originated from its popularity with porters. Porter is a type of ale.

A barrel-aged beer is a beer that has been aged for a period of time in a wooden barrel. Typically, these barrels once housed bourbon, whisky, wine, or, to a lesser extent, brandy, sherry, or port. There is a particular tradition of barrel ageing beer in Belgium, notably of lambic beers. The first bourbon barrel-aged beers were produced in the United States in the early 1990s.