Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat transfer. "Refrigeration" is sometimes added to the field's abbreviation as HVAC&R or HVACR, or "ventilation" is dropped, as in HACR.

Weatherization or weatherproofing is the practice of protecting a building and its interior from the elements, particularly from sunlight, precipitation, and wind, and of modifying a building to reduce energy consumption and optimize energy efficiency.

Ventilation is the intentional introduction of outdoor air into a space. Ventilation is mainly used to control indoor air quality by diluting and displacing indoor pollutants; it can also be used to control indoor temperature, humidity, and air motion to benefit thermal comfort, satisfaction with other aspects of the indoor environment, or other objectives.

A blower door is a machine used to perform a building air leakage test. It can also be used to measure airflow between building zones, to test ductwork airtightness and to help physically locate air leakage sites in the building envelope.

A vapor barrier is any material used for damp proofing, typically a plastic or foil sheet, that resists diffusion of moisture through the wall, floor, ceiling, or roof assemblies of buildings and of packaging to prevent interstitial condensation. Technically, many of these materials are only vapor retarders as they have varying degrees of permeability.

The stack effect or chimney effect is the movement of air into and out of buildings through unsealed openings, chimneys, flue-gas stacks, or other containers, resulting from air buoyancy. Buoyancy occurs due to a difference in indoor-to-outdoor air density resulting from temperature and moisture differences. The result is either a positive or negative buoyancy force. The greater the thermal difference and the height of the structure, the greater the buoyancy force, and thus the stack effect. The stack effect helps drive natural ventilation, air infiltration, and fires.

Ducts are conduits or passages used in heating, ventilation, and air conditioning (HVAC) to deliver and remove air. The needed airflows include, for example, supply air, return air, and exhaust air. Ducts commonly also deliver ventilation air as part of the supply air. As such, air ducts are one method of ensuring acceptable indoor air quality as well as thermal comfort.

Passive ventilation is the process of supplying air to and removing air from an indoor space without using mechanical systems. It refers to the flow of external air to an indoor space as a result of pressure differences arising from natural forces.

Infiltration is the unintentional or accidental introduction of outside air into a building, typically through cracks in the building envelope and through use of doors for passage. Infiltration is sometimes called air leakage. The leakage of room air out of a building, intentionally or not, is called exfiltration. Infiltration is caused by wind, negative pressurization of the building, and by air buoyancy forces known commonly as the stack effect.

Air barriers control air leakage into and out of the building envelope. Air barrier products may take several forms:

Air changes per hour, abbreviated ACPH or ACH, or air change rate is the number of times that the total air volume in a room or space is completely removed and replaced in an hour. If the air in the space is either uniform or perfectly mixed, air changes per hour is a measure of how many times the air within a defined space is replaced each hour. Perfectly mixed air refers to a theoretical condition where supply air is instantly and uniformly mixed with the air already present in a space, so that conditions such as age of air and concentration of pollutants are spatially uniform.

A rainscreen is an exterior wall detail where the siding stands off from the moisture-resistant surface of an air/water barrier applied to the sheathing to create a capillary break and to allow drainage and evaporation. The rainscreen is the cladding or siding itself but the term rainscreen implies a system of building. Ideally the rainscreen prevents the wall air/water barrier from getting wet but because of cladding attachments and penetrations water is likely to reach this point, and hence materials are selected to be moisture tolerant and integrated with flashing. In some cases a rainscreen wall is called a pressure-equalized rainscreen wall where the ventilation openings are large enough for the air pressure to nearly equalize on both sides of the rain screen, but this name has been criticized as being redundant and is only useful to scientists and engineers.

Fire dampers are passive fire protection products used in heating, ventilation, and air conditioning (HVAC) ducts to prevent and isolate the spread of fire inside the ductwork through fire-resistance rated walls and floors. Fire/smoke dampers are similar to fire dampers in fire resistance rating, and also prevent the spread of smoke inside the ducts. When a rise in temperature occurs, the fire damper closes, usually activated by a thermal element which melts at temperatures higher than ambient but low enough to indicate the presence of a fire, allowing springs to close the damper blades. Fire dampers can also close following receipt of an electrical signal from a fire alarm system utilising detectors remote from the damper, indicating the sensing of heat or smoke in the building occupied spaces or in the HVAC duct system.

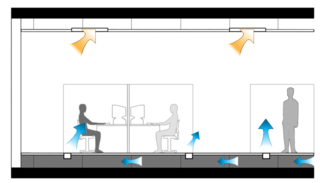

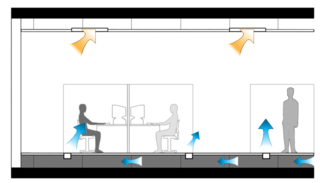

Underfloor air distribution (UFAD) is an air distribution strategy for providing ventilation and space conditioning in buildings as part of the design of a HVAC system. UFAD systems use an underfloor supply plenum located between the structural concrete slab and a raised floor system to supply conditioned air to supply outlets, located at or near floor level within the occupied space. Air returns from the room at ceiling level or the maximum allowable height above the occupied zone.

A duct leakage tester is a diagnostic tool designed to measure the airtightness of forced air heating, ventilating and air-conditioning (HVAC) ductwork. A duct leakage tester consists of a calibrated fan for measuring an air flow rate and a pressure sensing device to measure the pressure created by the fan flow. The combination of pressure and fan flow measurements are used to determine the ductwork airtightness. The airtightness of ductwork is useful knowledge when trying to improve energy conservation.

Dynamic insulation is a form of insulation where cool outside air flowing through the thermal insulation in the envelope of a building will pick up heat from the insulation fibres. Buildings can be designed to exploit this to reduce the transmission heat loss (U-value) and to provide pre-warmed, draft free air to interior spaces. This is known as dynamic insulation since the U-value is no longer constant for a given wall or roof construction but varies with the speed of the air flowing through the insulation. Dynamic insulation is different from breathing walls. The positive aspects of dynamic insulation need to be weighed against the more conventional approach to building design which is to create an airtight envelope and provide appropriate ventilation using either natural ventilation or mechanical ventilation with heat recovery. The air-tight approach to building envelope design, unlike dynamic insulation, results in a building envelope that provides a consistent performance in terms of heat loss and risk of interstitial condensation that is independent of wind speed and direction. Under certain wind conditions a dynamically insulated building can have a higher heat transmission loss than an air-tight building with the same thickness of insulation. Often the air enters at about 15 °C.

Airflow, or air flow, is the movement of air. The primary cause of airflow is the existence of air. Air behaves in a fluid manner, meaning particles naturally flow from areas of higher pressure to those where the pressure is lower. Atmospheric air pressure is directly related to altitude, temperature, and composition.

Air Infiltration and Ventilation Centre (AIVC) is the International Energy Agency information centre on energy efficient ventilation of buildings.

TightVent Europe is a platform focused on building and ductwork airtightness issues. The platform's creation was triggered to meet the 2020 targets of the Directive on the energy performance of buildings and overcome the challenges related to envelope and ductwork leakage towards the generalization of nearly zero-energy buildings. The platform's main activities include producing and disseminating policy-oriented publications, networking among local or national airtightness associations, and organizing conferences, workshops and webinars.

Ductwork airtightness can be defined as the resistance to inward or outward air leakage through the ductwork envelope. This air leakage is driven by differential pressures across the ductwork envelope due to the combined effects of stack and fan operation.