Bead weaving is a set of techniques for weaving sheets and objects of seed beads. Threads are strung through and/or around the beads to hold them together. It can be done either on a loom or using one of a number of off-loom stitches.

Knitting is a method for production of textile fabrics by interlacing yarn loops with loops of the same or other yarns. It is used to create many types of garments. Knitting may be done by hand or by machine.

Nålebinding is a fabric creation technique predating both knitting and crochet. Also known in English as "knotless netting", "knotless knitting", or "single-needle knitting", the technique is distinct from crochet in that it involves passing the full length of the working thread through each loop, unlike crochet where the work is formed only of loops, never involving the free end. It also differs from knitting in that lengths must be pieced together during the process of nålebinding, rather than a continuous strand of yarn that can easily be pulled out. Archaeological specimens of fabric made by nålebinding can be difficult to distinguish from knitted fabric.

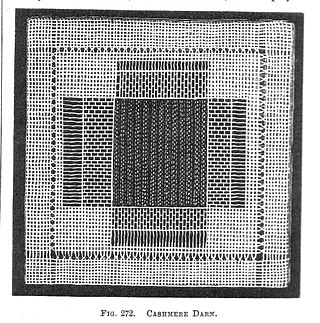

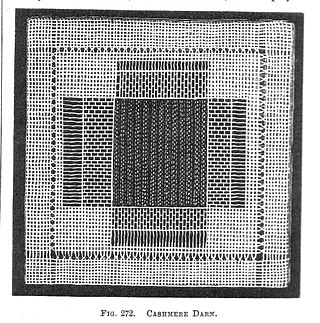

Darning is a sewing technique for repairing holes or worn areas in fabric or knitting using needle and thread alone. It is often done by hand, but using a sewing machine is also possible. Hand darning employs the darning stitch, a simple running stitch in which the thread is "woven" in rows along the grain of the fabric, with the stitcher reversing direction at the end of each row, and then filling in the framework thus created, as if weaving. Darning is a traditional method for repairing fabric damage or holes that do not run along a seam, and where patching is impractical or would create discomfort for the wearer, such as on the heel of a sock.

The term "gauge" is used in knitting to describe the fineness size of knitting machines. It is used in both hand knitting and machine knitting. The phrase in both instances refers to the number of stitches per inch rather than the size of the finished article of clothing. The gauge is calculated by counting the stitches or needles across a number of inches, then dividing by the sample's width in inches.

Combined knitting or combination knitting is a knitting method that combines elements of Eastern-style knitting with the Western techniques. The name was suggested by Mary Thomas in her 1938 book "Mary Thomas's Knitting Book", where she described the method as "..the better way to work in Flat Knitting. The resulting fabric is more even and closer in construction." By wrapping the yarn the opposite way while purling, the knitter changes the orientation of the resulting loops; then the next row's knit stitches can be formed by inserting the needle through the back leg, rather than through the front leg, without twisting the stitch. This method is suitable for all knitted fabrics from the basic Stockinette stitch, to any other technique, such as Fair Isle, circular knitting, or lace knitting.

A knitting machine is a device used to create knitted fabrics in a semi or fully automated fashion. There are numerous types of knitting machines, ranging from simple spool or board templates with no moving parts to highly complex mechanisms controlled by electronics. All, however, produce various types of knitted fabrics, usually either flat or tubular, and of varying degrees of complexity. Pattern stitches can be selected by hand manipulation of the needles, push-buttons and dials, mechanical punch cards, or electronic pattern reading devices and computers.

In knitting, an increase is the creation of one or more new stitches, which may be done by various methods that create distinctive effects in the fabric. Most knitting increases either lean towards the left or the right.

Basic knitted fabrics include stocking stitch, reverse stocking stitch, garter stitch, seed stitch, faggoting, and tricot. In some cases, these fabrics appear differently on the right side than on the wrong side.

Warp knitting is defined as a loop-forming process in which the yarn is fed into the knitting zone, parallel to the fabric selvage. It forms vertical loops in one course and then moves diagonally to knit the next course. Thus the yarns zigzag from side to side along the length of the fabric. Each stitch in a course is made by many different yarns. Each stitch in one wale is made by several different yarns.

Flat knitting is a method for producing knitted fabrics in which the work is turned periodically; that is, the fabric is worked with alternating sides facing the knitter. Another method of achieving the same result is to knit alternately from right to left and left to right without turning; this back-and-forth technique requires either innate or learned ambidextrous motor skills. The two sides of the fabric are usually designated as the right side and the wrong side.

In knitting, picking up stitches means adding stitches to the knitting needle that were previously bound off or belong to the selvage.

In knitting, crochet and other handmade textile arts, blocking is a final stage of handmade textile production that adjusts the shape and size of the finished piece. Not all pieces need blocking; however, blocking is standard for lace work and is not uncommon in sweaters, socks, and other solid projects. Through heat and moisture, blocking sets the stitches and standardizes the final dimensions, and may enhance the drape. Hand manufacture places natural stresses on fabrics that may result in deviations from its intended shape and size. Blocking is only effective on natural fibres but a technique called killing may be used on synthetic fibres to achieve an effect similar to blocking.

Knitted fabric is a textile that results from knitting, the process of inter-looping of yarns or inter-meshing of loops. Its properties are distinct from woven fabric in that it is more flexible and can be more readily constructed into smaller pieces, making it ideal for socks and hats.

A selvage or selvedge is a "self-finished" edge of a piece of fabric which keeps it from unraveling and fraying. The term "self-finished" means that the edge does not require additional finishing work, such as hem or bias tape, to prevent fraying.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fiber from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, with color and patterns, which turns it into cloth. The machine used for weaving is the loom. For decoration, the process of coloring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

Complete garment knitting is a next-generation form of fully fashioned knitting that adds the capability of making a 3-dimensional full garment. Unlike other fully fashioned knitting, where the shaped pieces must still be sewn together, finished complete knitted garments do not have seams. The knitting machines' computerized instructions direct movement of hundreds of needles to construct and connect several tubular knitted forms to create a complete garment in a single production step.

Waffle fabric, also known as honeycomb fabric, has raised threads that form small rectangles. It can be made by either weaving or knitting. Waffle weave is a further exploitation of plain weave and twill weave which produces a three-dimensional effect. The combination of warp and weft floats creates the structure. It is woven partly on tabby areas surrounded by ridges of long floats. The weave consists of warp and weft floats arranged around a plain weave center. The warp and weft threads are interlaced and floating in a way that creates small square ridges and hollows in the fabric in a regular pattern.

Sewing is the craft of fastening or attaching objects using stitches made with needle and thread. Sewing is one of the oldest of the textile arts, arising in the Paleolithic Era. Although usually associated with clothing and household linens, sewing is used in a variety of crafts and industries, including shoemaking, upholstery, sailmaking, bookbinding and the manufacturing of some kinds of sporting goods. Sewing is the fundamental process underlying a variety of textile arts and crafts, including embroidery, tapestry, quilting, appliqué and patchwork.

Malimo is a textile manufacturing technique in which warp and weft yarns are sewn together. The method is also referred to as "stitch-bonding." It was invented in Eastern Germany in the 1950s. Malimo is used in a variety of applications, including apparel fabrics, wind turbine wings and isolation fabrics, and aerospace.