A flat-four engine, also known as a horizontally opposed-four engine or boxer engine, is a four-cylinder piston engine with two banks of cylinders lying on opposite sides of a common crankshaft. The most common type of flat-four engine is the boxer-four engine, each pair of opposed pistons moves inwards and outwards at the same time.

Lycoming Engines is a major American manufacturer of aircraft engines. With a factory in Williamsport, Pennsylvania, Lycoming produces a line of horizontally opposed, air-cooled, four, six and eight-cylinder engines including the only FAA-certified aerobatic and helicopter piston engines on the market.

Continental Aerospace Technologies is an aircraft engine manufacturer located at the Brookley Aeroplex in Mobile, Alabama, United States. It was originally spun off from automobile engine manufacturer Continental Motors Company in 1929 and owned by Teledyne Technologies from 1969 until December 2010. The company is now part of Aviation Industry Corporation of China (AVIC), which is a Government of the People's Republic of China state-owned aerospace company headquartered in Beijing.

The Cessna AT-17 Bobcat or Cessna Crane is a twin-engine advanced trainer aircraft designed and made in the United States, and used during World War II to bridge the gap between single-engine trainers and larger multi-engine combat aircraft. The commercial version was the Model T-50, from which the military versions were developed.

The Lycoming XR-7755 was the largest piston aircraft engine ever built in the United States, with 36 cylinders totaling about 7,750 in3 (127 L) of displacement and a power output of 5,000 horsepower (3,700 kilowatts). It was originally intended to be used in the "European bomber" that eventually emerged as the Convair B-36. Only two examples were built before the project was terminated in 1946.

The Cessna 190 and 195 Businessliner are a family of light single radial engine powered, conventional landing gear equipped, general aviation aircraft which were manufactured by Cessna between 1947 and 1954.

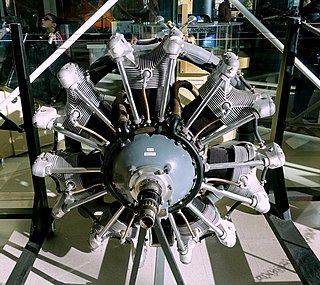

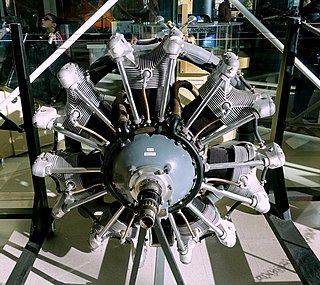

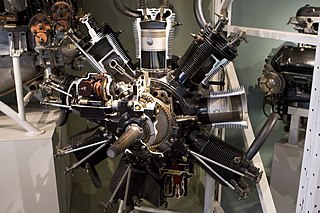

The Armstrong Siddeley Lynx is a British seven-cylinder aero engine developed by Armstrong Siddeley. It was developed as a single row version of the two-row Armstrong Siddeley Jaguar. Testing began in 1920 and 6,000 had been produced by 1939. In Italy Alfa Romeo built a 200 horsepower (150 kW) licensed version of this engine named the Alfa Romeo Lynx.

The Warner Scarab is an American seven-cylinder radial aircraft engine, that was manufactured by the Warner Aircraft Corporation of Detroit, Michigan in 1928 through to the early 1940s. In military service the engine was designated R-420.

The Continental R-670 was a seven-cylinder four-stroke radial aircraft engine produced by Continental displacing 668 cubic inches and a dry weight of 465 lb (211 kg). Horsepower varied from 210 to 240 at 2,200 rpm. The engine was the successor to Continental's first radial engine, the 170 hp Continental A-70. This engine was used on many aircraft in the 1930s and 1940s. The R-670 was widely used in the PT-17 Stearman primary training aircraft of the U.S. military.

The Alvis Leonides Major is a British air-cooled 14-cylinder radial aero engine developed by Alvis from the earlier nine-cylinder Leonides.

The Siemens-Halske Sh 14 was a seven-cylinder air-cooled radial engine for aircraft produced in Germany in the 1920s and 1930s. First run in 1928, it was rated at 93 kW (125 hp). It was briefly distributed in the United States by Ryan Aeronautical as the Yankee 7.

The Jacobs R-755 is a seven-cylinder, air-cooled, radial engine for aircraft manufactured in the United States by the Jacobs Aircraft Engine Company.

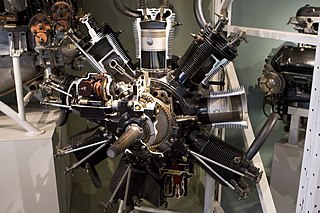

The Lawrance J-1 was an engine developed by Charles Lanier Lawrance and used in American aircraft in the early 1920s. It was a nine-cylinder, air-cooled radial design.

The Wright R-790 Whirlwind was a series of nine-cylinder air-cooled radial aircraft engines built by Wright Aeronautical Corporation, with a total displacement of about 790 cubic inches (12.9 L) and around 200 horsepower (150 kW). These engines were the earliest members of the Wright Whirlwind engine family.

The Lycoming R-680 is a nine-cylinder air-cooled radial engine, the first aero engine produced by Lycoming. The engine was produced in two types, the E and B series; both are essentially the same. The B4E was available in a trainer version with a front exhaust collector "ring" for use without cylinder air baffles. R-680 received Approved Type Certificate No. 42 on 4 Feb 1930.

The Jacobs R-915 or Jacobs L-6 is a seven-cylinder, air-cooled, radial engine for aircraft manufactured in the United States, production started in 1936.

The Jacobs R-830 or L-5 is a seven-cylinder, air-cooled, radial engine for aircraft manufactured in the United States by the Jacobs Aircraft Engine Company, beginning in 1935.

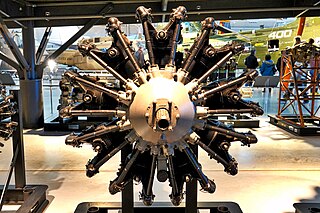

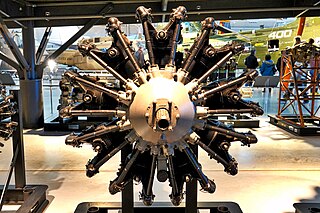

The Wright Whirlwind was a family of air-cooled radial aircraft engines built by Wright Aeronautical. The family began with nine-cylinder engines, and later expanded to include five-cylinder and seven-cylinder varieties. Fourteen-cylinder twin-row versions were also developed, but these were not commercially produced.

Lawrance Aero Engine Company was an American aircraft engine manufacturer. Founded by engine pioneer Charles Lawrance, it designed one of the first successful air-cooled radial engines. It existed for only 5 years, being acquired by Wright Aeronautical, a much larger company better able to mass-produce Lawrance's radial engines.

The Comet 7-cylinder radials were a family of air-cooled radial engines, designed and built by the Comet Engine Corporation at Madison, Wisconsin from around 1927.