A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel (aggregate) together. Cement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete. Concrete is the most widely used material in existence and is behind only water as the planet's most-consumed resource.

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and non-specialty grout. It was developed from other types of hydraulic lime in England in the early 19th century by Joseph Aspdin, and is usually made from limestone. It is a fine powder, produced by heating limestone and clay minerals in a kiln to form clinker, and then grinding the clinker with the addition of several percent gypsum. Several types of portland cement are available. The most common, historically called ordinary portland cement (OPC), is grey, but white portland cement is also available. Its name is derived from its resemblance to Portland stone which is quarried on the Isle of Portland in Dorset, England. It was named by Joseph Aspdin who obtained a patent for it in 1824. His son William Aspdin is regarded as the inventor of "modern" portland cement due to his developments in the 1840s.

A lime kiln is a kiln used for the calcination of limestone (calcium carbonate) to produce the form of lime called quicklime (calcium oxide). The chemical equation for this reaction is

Rutland Railway Museum, now trading as Rocks by Rail: The Living Ironstone Museum, is a heritage railway on part of a former Midland Railway mineral branch line. It is situated north east of Oakham, in Rutland, England.

Ketton is a village and civil parish in Rutland in the East Midlands of England. It is about 8 miles (13 km) east of Oakham and 3 miles (5 km) west of Stamford, Lincolnshire. The 2011 Census recorded a parish population of 1,926, making it the fourth largest settlement in Rutland, after Oakham, Uppingham and Cottesmore. The village has a primary school.

ENCI is a Dutch company based in Maastricht, Rotterdam and IJmuiden. Their core business activity used to consist of the digging of marl out of St Pietersberg, which they used to make cement. The company has been around since 1924, with some key locations being in Maastricht and Sint-Pietersberg. The Maastricht location was closed in 2020, along with the cement production.

Aberthaw Cement Works are cement works in the Vale of Glamorgan near the village of East Aberthaw in Wales.

Hanson Cement was a cement production company located in the United Kingdom. It was called Castle Cement until it was rebranded in 2009. The company is now owned by HeidelbergCement, with the UK business managed by Heidelberg Materials UK. Hanson Cement has a long history dating back to the early 19th century, when it was founded as the Portland Cement Company.

Cement kilns are used for the pyroprocessing stage of manufacture of portland and other types of hydraulic cement, in which calcium carbonate reacts with silica-bearing minerals to form a mixture of calcium silicates. Over a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant. As the main energy-consuming and greenhouse-gas–emitting stage of cement manufacture, improvement of kiln efficiency has been the central concern of cement manufacturing technology. Emissions from cement kilns are a major source of greenhouse gas emissions, accounting for around 2.5% of non-natural carbon emissions worldwide.

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill. The raw milling stage of the process effectively defines the chemistry of the finished cement, and has a large effect upon the efficiency of the whole manufacturing process.

Heidelberg Materials is a German multinational building materials company headquartered in Heidelberg, Germany. Formerly known as HeidelbergCement AG, the company has rebranded as Heidelberg Materials in September 2022. It is a DAX corporation and stands as one of the world's largest building materials companies. On 1 July 2016, HeidelbergCement AG completed the acquisition of a 45% shareholding in Italcementi. This acquisition made HeidelbergCement the number one producer of construction aggregates, the second-largest in cement and the third-largest in ready-mixed concrete worldwide. In the 2020 Forbes Global 2000, HeidelbergCement was ranked as the 678th -largest public company in the world.

Adbri, formerly Adelaide Brighton Cement, is an Australian manufacturer of cement, lime and dry blended products.

Rutland is a ceremonial county in the East Midlands of England. It borders Leicestershire to the north and west, Lincolnshire to the north-east, and Northamptonshire to the south-west. Oakham is the largest town and county town.

Mysore Cements Limited is one of major producers of Cement in south India since its establishment in 1958 – 59 by Karnataka-based industrialist Sarangapani Mudaliar and by collaboration of Kaisers USA as a Public Limited Company The company produced its major output of 1 ton cement with the investment of about 20 million Rupees, in 1962. MCL was immediately taken over by Kaisers and G.D Birla and from then the following years company started producing more cement and it was 4 tpa by the end of year 1968. With an investment of 23 million, MCL produced 6 tpa of cement in Ammasandra unit Based in Tumkur District of Karnataka State. After the death of G.D Birla, in 1983 MCL was totally under control of Birlas and Shri. S.K Birla, grandson of GD Birla was declared the chairman of the organisation.

Thos. W. Ward Ltd was a Sheffield, Yorkshire, steel, engineering and cement business, which began as coal and coke merchants. It expanded into recycling metal for Sheffield's steel industry, and then the supply and manufacture of machinery.

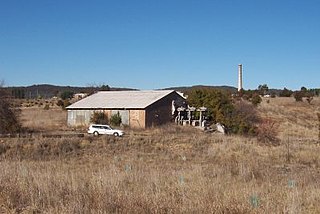

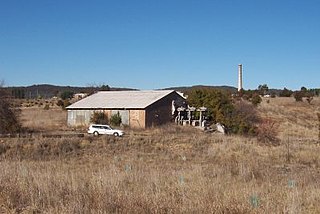

Raffan's Mill and Brick Bottle Kilns is a heritage-listed lime kiln at Carlton Road, Portland, New South Wales, Australia. It was built from 1884 to 1895 by George Raffan and Alexander Currie. It is also known as Raffan's Mill and Brick Bottle Kilns Precinct, Portland Cement Works Site, Williwa Street Portland. The property is owned by Boral. It was added to the New South Wales State Heritage Register on 3 August 2012.

Portland Cement Works Precinct is a heritage-listed former cement works and limestone quarries and now disused industrial site at Williwa Street, Portland, City of Lithgow, New South Wales, Australia. It was designed and built in various stages from 1890 to 2003. It is also known as Portland Cement Group and Commonwealth Portland Cement Company Ltd. The property is owned by Boral Limited. It was added to the New South Wales State Heritage Register on 3 August 2012.

Hope Cement Works, is a cement plant located near to the village of Hope in Derbyshire, England. The plant is mostly self-contained with its own shale and limestone quarries adjacent, with only fuel and small amounts of additives needing to be brought in. The site is located inside the Peak District National Park, and so is subject to tighter planning restrictions than other cement plants in the United Kingdom. It is now the largest cement plant in the United Kingdom, and is also one of the largest emitters of CO2 within the national park.

Horton Quarry is a limestone quarry near to Horton-in-Ribblesdale, North Yorkshire, England. The quarry, which is some 6 miles (9.7 km) north of Settle, has been operating since at least 1889, and produces limestone for a variety of purposes. Stone used to be exported from the quarry by rail, but now leaves by lorry, although there are plans to re-instate the railway sidings. The quarry used to produce its own lime by roasting the limestone in big kilns on the site, but the last of these were removed in the 1980s. Since 2000, the quarry has been owned and operated by Heidelberg Materials UK.

The Antoing cement kiln is in the Belgian province of Hainaut. The facility is next to the Scheldt River in the Tournai region. It was built in 1929 under CBR which was later taken over by Heidelberg Materials.