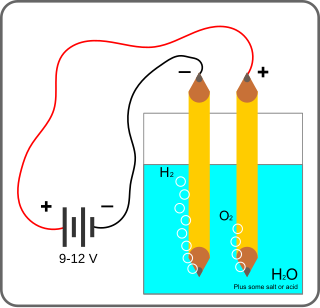

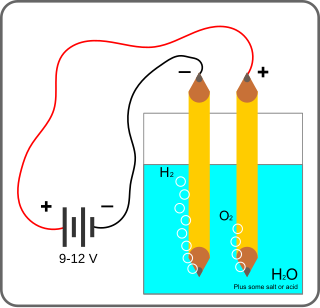

In chemistry and manufacturing, electrolysis is a technique that uses direct electric current (DC) to drive an otherwise non-spontaneous chemical reaction. Electrolysis is commercially important as a stage in the separation of elements from naturally occurring sources such as ores using an electrolytic cell. The voltage that is needed for electrolysis to occur is called the decomposition potential. The word "lysis" means to separate or break, so in terms, electrolysis would mean "breakdown via electricity".

The hydrogen economy is an umbrella term that draws together the roles hydrogen can play alongside renewable electricity to decarbonize specific economic sectors, sub-sectors and activities which may be technically difficult to decarbonize through other means, or where cheaper and more energy-efficient clean solutions are not available. In this context, hydrogen economy encompasses hydrogen’s production through to end-uses in ways that substantively contribute to avoiding the use of fossil fuels and mitigating greenhouse gas emissions.

A regenerative fuel cell or reverse fuel cell (RFC) is a fuel cell run in reverse mode, which consumes electricity and chemical B to produce chemical A. By definition, the process of any fuel cell could be reversed. However, a given device is usually optimized for operating in one mode and may not be built in such a way that it can be operated backwards. Standard fuel cells operated backwards generally do not make very efficient systems unless they are purpose-built to do so as with high-pressure electrolysers, regenerative fuel cells, solid-oxide electrolyser cells and unitized regenerative fuel cells.

High-temperature electrolysis is a technology for producing hydrogen from water at high temperatures.

The methanol economy is a suggested future economy in which methanol and dimethyl ether replace fossil fuels as a means of energy storage, ground transportation fuel, and raw material for synthetic hydrocarbons and their products. It offers an alternative to the proposed hydrogen economy or ethanol economy, although these concepts are not exclusive. Methanol can be produced from a variety of sources including fossil fuels as well as agricultural products and municipal waste, wood and varied biomass. It can also be made from chemical recycling of carbon dioxide.

A hydrogen station is a storage or filling station for hydrogen fuel. The hydrogen is dispensed by weight. There are two filling pressures in common use: H70 or 700 bar, and the older standard H35 or 350 bar. As of 2021, around 550 filling stations were available worldwide.

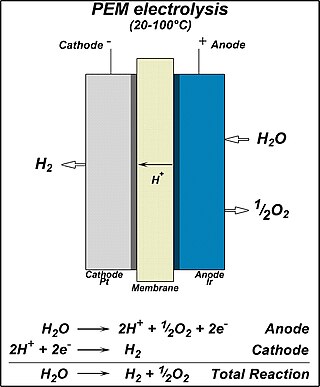

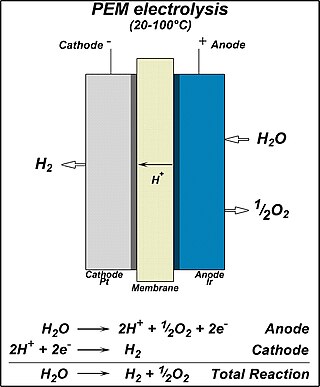

A proton-exchange membrane, or polymer-electrolyte membrane (PEM), is a semipermeable membrane generally made from ionomers and designed to conduct protons while acting as an electronic insulator and reactant barrier, e.g. to oxygen and hydrogen gas. This is their essential function when incorporated into a membrane electrode assembly (MEA) of a proton-exchange membrane fuel cell or of a proton-exchange membrane electrolyser: separation of reactants and transport of protons while blocking a direct electronic pathway through the membrane.

Electrolysis of water is using electricity to split water into oxygen and hydrogen gas by electrolysis. Hydrogen gas released in this way can be used as hydrogen fuel, but must be kept apart from the oxygen as the mixture would be extremely explosive. Separately pressurised into convenient 'tanks' or 'gas bottles', hydrogen can be used for oxyhydrogen welding and other applications, as the hydrogen / oxygen flame can reach approximately 2,800°C.

Hydrogen production is the family of industrial methods for generating hydrogen gas. There are four main sources for the commercial production of hydrogen: natural gas, oil, coal, and electrolysis of water; which account for 48%, 30%, 18% and 4% of the world's hydrogen production respectively. Fossil fuels are the dominant source of industrial hydrogen. As of 2020, the majority of hydrogen (~95%) is produced by steam reforming of natural gas and other light hydrocarbons, partial oxidation of heavier hydrocarbons, and coal gasification. Other methods of hydrogen production include biomass gasification and methane pyrolysis. Methane pyrolysis and water electrolysis can use any source of electricity including renewable energy.

The HyNor-project was a nationally supported project which purpose was to facilitate and coordinate the introduction of hydrogen as a fuel in Norway, running from 2003 to 2012. Toward the commercial introduction of hydrogen vehicles in 2015, the HyNor-project focused on acquiring an early pre-commercial fleet of hydrogen vehicles, and keeping a close dialogue with the leading car manufacturers and other similar initiatives in the Nordic countries and around the world.

High-pressure electrolysis (HPE) is the electrolysis of water by decomposition of water (H2O) into oxygen (O2) and hydrogen gas (H2) due to the passing of an electric current through the water. The difference with a standard proton exchange membrane electrolyzer is the compressed hydrogen output around 12–20 megapascals (120–200 bar) at 70 °C. By pressurising the hydrogen in the electrolyser the need for an external hydrogen compressor is eliminated, the average energy consumption for internal differential pressure compression is around 3%.

A solid oxide electrolyzer cell (SOEC) is a solid oxide fuel cell that runs in regenerative mode to achieve the electrolysis of water by using a solid oxide, or ceramic, electrolyte to produce hydrogen gas and oxygen. The production of pure hydrogen is compelling because it is a clean fuel that can be stored, making it a potential alternative to batteries, methane, and other energy sources. Electrolysis is currently the most promising method of hydrogen production from water due to high efficiency of conversion and relatively low required energy input when compared to thermochemical and photocatalytic methods.

ITM Power plc is an energy storage and clean fuel company founded in the UK in 2001. It designs, manufactures, and integrates electrolysers based on proton exchange membrane (PEM) technology to produce green hydrogen using renewable electricity and tap water. Hydrogen produced via electrolysis is used for mobility, Power-to-X, and industry.

Power-to-gas is a technology that uses electric power to produce a gaseous fuel. When using surplus power from wind generation, the concept is sometimes called windgas.

Proton exchange membrane(PEM) electrolysis is the electrolysis of water in a cell equipped with a solid polymer electrolyte (SPE) that is responsible for the conduction of protons, separation of product gases, and electrical insulation of the electrodes. The PEM electrolyzer was introduced to overcome the issues of partial load, low current density, and low pressure operation currently plaguing the alkaline electrolyzer. It involves a proton-exchange membrane.

Hydrogenics is a developer and manufacturer of hydrogen generation and fuel cell products based on water electrolysis and proton-exchange membrane (PEM) technology. Hydrogenics is divided into two business units: OnSite Generation and Power Systems. Onsite Generation is headquartered in Oevel, Belgium and had 73 full-time employees as of December 2013. Power Systems is based in Mississauga, Ontario, Canada, with a satellite facility in Gladbeck, Germany. It had 62 full-time employees as of December 2013. Hydrogenics maintains operations in Belgium, Canada and Germany with satellite offices in the United States, Indonesia, Malaysia and Russia.

Green hydrogen (GH2 or GH2) is hydrogen produced by the electrolysis of water, using renewable electricity. Production of green hydrogen causes significantly lower greenhouse gas emissions than production of grey hydrogen, which is derived from fossil fuels without carbon capture.

Bruno Georges Pollet BSc(Hons) MSc PhD FRSC, is a French chemist, electrochemist and electrochemical engineer, a Fellow of the Royal Society of Chemistry, professor of chemistry, director of the Green Hydrogen Lab, co-director of the Institute for Hydrogen Research at the Université du Québec à Trois-Rivières in Canada. He has worked on Hydrogen Energy in the UK, Japan, South Africa, Norway and Canada, and has both industrial and academic experience. He is regarded as one of the most prominent Hydrogen experts in the world.

Anion exchange membrane(AEM) electrolysis is the electrolysis of water that utilises a semipermeable membrane that conducts hydroxide ions (OH−) called an anion exchange membrane. Like a proton-exchange membrane (PEM), the membrane separates the products, provides electrical insulation between electrodes, and conducts ions. Unlike PEM, AEM conducts hydroxide ions. The major advantage of AEM water electrolysis is that a high-cost noble metal catalyst is not required, low-cost transition metal catalyst can be used instead. AEM electrolysis is similar to alkaline water electrolysis, which uses a non-ion-selective separator instead of an anion-exchange membrane.

Ohmium is a Hydrogen production company based in Palo Alto, California.