Analytical chemistry studies and uses instruments and methods to separate, identify, and quantify matter. In practice, separation, identification or quantification may constitute the entire analysis or be combined with another method. Separation isolates analytes. Qualitative analysis identifies analytes, while quantitative analysis determines the numerical amount or concentration.

In nutrition, biology, and chemistry, fat usually means any ester of fatty acids, or a mixture of such compounds, most commonly those that occur in living beings or in food.

Olive oil is a liquid fat obtained by pressing whole olives, the fruit of Olea europaea, a traditional tree crop of the Mediterranean Basin, and extracting the oil.

Titration is a common laboratory method of quantitative chemical analysis to determine the concentration of an identified analyte. A reagent, termed the titrant or titrator, is prepared as a standard solution of known concentration and volume. The titrant reacts with a solution of analyte to determine the analyte's concentration. The volume of titrant that reacted with the analyte is termed the titration volume.

A triglyceride is an ester derived from glycerol and three fatty acids. Triglycerides are the main constituents of body fat in humans and other vertebrates as well as vegetable fat. They are also present in the blood to enable the bidirectional transference of adipose fat and blood glucose from the liver and are a major component of human skin oils.

Ultraviolet (UV) spectroscopy or ultraviolet–visible (UV–VIS) spectrophotometry refers to absorption spectroscopy or reflectance spectroscopy in part of the ultraviolet and the full, adjacent visible regions of the electromagnetic spectrum. Being relatively inexpensive and easily implemented, this methodology is widely used in diverse applied and fundamental applications. The only requirement is that the sample absorb in the UV-Vis region, i.e. be a chromophore. Absorption spectroscopy is complementary to fluorescence spectroscopy. Parameters of interest, besides the wavelength of measurement, are absorbance (A) or transmittance (%T) or reflectance (%R), and its change with time.

An acid–base titration is a method of quantitative analysis for determining the concentration of Brønsted-Lowry acid or base (titrate) by neutralizing it using a solution of known concentration (titrant). A pH indicator is used to monitor the progress of the acid–base reaction and a titration curve can be constructed.

Fatty acid metabolism consists of various metabolic processes involving or closely related to fatty acids, a family of molecules classified within the lipid macronutrient category. These processes can mainly be divided into (1) catabolic processes that generate energy and (2) anabolic processes where they serve as building blocks for other compounds.

In chemistry, acid value is a number used to quantify the acidity of a given chemical substance. It is the quantity of base, expressed as milligrams of KOH required to neutralize the acidic constituents in 1 gram of a sample. The acid value measures the acidity of water-insoluble substances like oils, fats, waxes and resins, which do not have a pH value.

Dielectric spectroscopy measures the dielectric properties of a medium as a function of frequency. It is based on the interaction of an external field with the electric dipole moment of the sample, often expressed by permittivity.

The smoke point, also referred to as the burning point, is the temperature at which an oil or fat begins to produce a continuous bluish smoke that becomes clearly visible, dependent upon specific and defined conditions. Smoke point values can vary greatly, depending on factors such as the volume of oil utilized, the size of the container, the presence of air currents, the type and source of light as well as the quality of the oil and its acidity content, otherwise known as free fatty acid (FFA) content. The more FFA an oil contains, the quicker it will break down and start smoking. The lower the value of FFA, the higher the smoke point. However, the FFA content typically represents less than 1% of the total oil and consequently renders smoke point a poor indicator of the capacity of a fat or oil to withstand heat.

The total acid number (TAN) is a measurement of acidity that is determined by the amount of potassium hydroxide in milligrams that is needed to neutralize the acids in one gram of oil. It is an important quality measurement of crude oil.

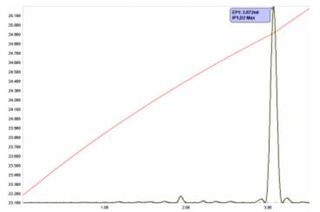

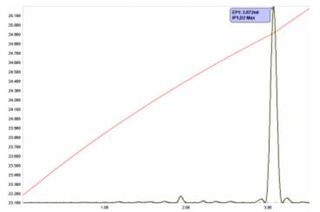

A thermometric titration is one of a number of instrumental titration techniques where endpoints can be located accurately and precisely without a subjective interpretation on the part of the analyst as to their location. Enthalpy change is arguably the most fundamental and universal property of chemical reactions, so the observation of temperature change is a natural choice in monitoring their progress. It is not a new technique, with possibly the first recognizable thermometric titration method reported early in the 20th century. In spite of its attractive features, and in spite of the considerable research that has been conducted in the field and a large body of applications that have been developed; it has been until now an under-utilized technique in the critical area of industrial process and quality control. Automated potentiometric titration systems have pre-dominated in this area since the 1970s. With the advent of cheap computers able to handle the powerful thermometric titration software, development has now reached the stage where easy to use automated thermometric titration systems can in many cases offer a superior alternative to potentiometric titrimetry.

In chemistry, the terms volatile acid and volatile acidity (VA) are used somewhat differently in various application areas.

Fatty acid esters (FAEs) are a type of ester that result from the combination of a fatty acid with an alcohol. When the alcohol component is glycerol, the fatty acid esters produced can be monoglycerides, diglycerides, or triglycerides. Dietary fats are chemically triglycerides.

Olive oil regulation and adulteration are complex issues overseen and studied by various governmental bodies, non-governmental organizations, and private researchers across the world. The most frequent type of adulteration is that oil of lower quality is mixed into olive oil.

Pirinixic acid is a peroxisome proliferator-activated receptor alpha (PPARα) agonist that is under experimental investigation for prevention of severe cardiac dysfunction, cardiomyopathy and heart failure as a result of lipid accumulation within cardiac myocytes. Treatment is primarily aimed at individuals with an adipose triglyceride lipase (ATGL) enzyme deficiency or mutation because of the essential PPAR protein interactions with free fatty acid monomers derived from the ATGL catalyzed lipid oxidation reaction. It was discovered as WY-14,643 in 1974.

In analytical chemistry, the hydroxyl value is defined as the number of milligrams of potassium hydroxide (KOH) required to neutralize the acetic acid taken up on acetylation of one gram of a chemical substance that contains free hydroxyl groups. The analytical method used to determine hydroxyl value traditionally involves acetylation of the free hydroxyl groups of the substance with acetic anhydride in pyridine solvent. After completion of the reaction, water is added, and the remaining unreacted acetic anhydride is converted to acetic acid and measured by titration with potassium hydroxide.

Cooking oil is a plant or animal liquid fat used in frying, baking, and other types of cooking. Oil allows higher cooking temperatures than water, making cooking faster and more flavorful, while likewise distributing heat, reducing burning and uneven cooking. It sometimes imparts its own flavor. Cooking oil is also used in food preparation and flavoring not involving heat, such as salad dressings and bread dips.

Base Number (BN) is a measurement of basicity that is expressed in terms of the number of milligrams of potassium hydroxide per gram of oil sample. BN is an important measurement in petroleum products, and the value varies depending on its application. BN generally ranges from 6–8 mg KOH/g in modern lubricants, 7–10 mg KOH/g for general internal combustion engine use and 10–15 mg KOH/g for diesel engine operations. BN is typically higher for marine grade lubricants, approximately 15-80 mg KOH/g, as the higher BN values are designed to increase the operating period under harsh operating conditions, before the lubricant requires replacement.