Related Research Articles

Pottery is the process and the products of forming vessels and other objects with clay and other raw materials, which are fired at high temperatures to give them a hard and durable form. The place where such wares are made by a potter is also called a pottery. The definition of pottery, used by the ASTM International, is "all fired ceramic wares that contain clay when formed, except technical, structural, and refractory products". End applications include tableware, decorative ware, sanitaryware, and in technology and industry such as electrical insulators and laboratory ware. In art history and archaeology, especially of ancient and prehistoric periods, pottery often means vessels only, and sculpted figurines of the same material are called terracottas.

Porcelain is a ceramic material made by heating raw materials, generally including kaolinite, in a kiln to temperatures between 1,200 and 1,400 °C. The greater strength and translucence of porcelain, relative to other types of pottery, arise mainly from vitrification and the formation of the mineral mullite within the body at these high temperatures. End applications include tableware, decorative ware such as figurines, and products in technology and industry such as electrical insulators and laboratory ware.

Earthenware is glazed or unglazed nonvitreous pottery that has normally been fired below 1,200 °C (2,190 °F). Basic earthenware, often called terracotta, absorbs liquids such as water. However, earthenware can be made impervious to liquids by coating it with a ceramic glaze, and is used for the great majority of modern domestic earthenware. The main other important types of pottery are porcelain, bone china, and stoneware, all fired at high enough temperatures to vitrify. End applications include tableware, decorative ware such as figurines.

Faience or faïence is the general English language term for fine tin-glazed pottery. The invention of a white pottery glaze suitable for painted decoration, by the addition of an oxide of tin to the slip of a lead glaze, was a major advance in the history of pottery. The invention seems to have been made in Iran or the Middle East before the ninth century. A kiln capable of producing temperatures exceeding 1,000 °C (1,830 °F) was required to achieve this result, the result of millennia of refined pottery-making traditions. The term is now used for a wide variety of pottery from several parts of the world, including many types of European painted wares, often produced as cheaper versions of porcelain styles.

Stoneware is a rather broad term for pottery fired at a relatively high temperature. A modern definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. End applications include tableware, decorative ware such as vases.

Pottery and porcelain, is one of the oldest Japanese crafts and art forms, dating back to the Neolithic period. Kilns have produced earthenware, pottery, stoneware, glazed pottery, glazed stoneware, porcelain, and blue-and-white ware. Japan has an exceptionally long and successful history of ceramic production. Earthenwares were made as early as the Jōmon period, giving Japan one of the oldest ceramic traditions in the world. Japan is further distinguished by the unusual esteem that ceramics holds within its artistic tradition, owing to the enduring popularity of the tea ceremony.

Salt-glaze or salt glaze pottery is pottery, usually stoneware, with a glaze of glossy, translucent and slightly orange-peel-like texture which was formed by throwing common salt into the kiln during the higher temperature part of the firing process. Sodium from the salt reacts with silica in the clay body to form a glassy coating of sodium silicate. The glaze may be colourless or may be coloured various shades of brown, blue, or purple.

Langley Mill Pottery was located in Langley Mill, Derbyshire on the Derbyshire – Nottinghamshire border. From its establishment in 1865 to its final closure in 1982, the pottery went through five distinct periods of ownership, producing a wide range of stoneware ranging from salt glazed ink bottles, utilitarian items and tableware to high quality and original art pottery.

Ding ware, Ting ware or Dingyao are Chinese ceramics, mostly porcelain, that were produced in the prefecture of Dingzhou in Hebei in northern China. The main kilns were at Jiancicun or Jianci in Quyang County. They were produced between the Tang and Yuan dynasties of imperial China, though their finest period was in the 11th century, under the Northern Song. The kilns "were in almost constant operation from the early eighth until the mid-fourteenth century."

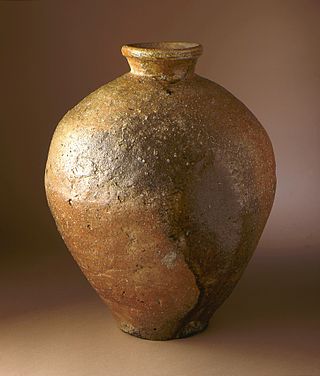

Shigaraki ware (信楽焼) is a type of stoneware pottery made in Shigaraki area, Japan. The kiln is one of the Six Ancient Kilns in Japan. Although figures representing the tanuki are a popular product included as Shigaraki ware, the kiln and local pottery tradition has a long history.

Royal Doulton is an English ceramic and home accessories manufacturer that was founded in 1815. Operating originally in Vauxhall, London, and later moving to Lambeth, in 1882 it opened a factory in Burslem, Stoke-on-Trent, in the centre of English pottery. From the start, the backbone of the business was a wide range of utilitarian wares, mostly stonewares, including storage jars, tankards and the like, and later extending to drain pipes, lavatories, water filters, electrical porcelain and other technical ceramics. From 1853 to 1901, its wares were marked Doulton & Co., then from 1901, when a royal warrant was given, Royal Doulton.

Chinese ceramics show a continuous development since pre-dynastic times and are one of the most significant forms of Chinese art and ceramics globally. The first pottery was made during the Palaeolithic era. Chinese ceramics range from construction materials such as bricks and tiles, to hand-built pottery vessels fired in bonfires or kilns, to the sophisticated Chinese porcelain wares made for the imperial court and for export. Porcelain was a Chinese invention and is so identified with China that it is still called "china" in everyday English usage.

This is a list of pottery and ceramic terms.

Shiwan ware is Chinese pottery from kilns located in the Shiwanzhen Subdistrict of the provincial city of Foshan, near Guangzhou, Guangdong. It forms part of a larger group of wares from the coastal region known collectively as "Canton stonewares". The hilly, wooded, area provided slopes for dragon kilns to run up, and fuel for them, and was near major ports.

Buena Vista is an unincorporated community in Polk County, Oregon, United States. It is located on the Willamette River, and is the western landing for the Buena Vista Ferry. It is approximately 7 miles (11 km) south-southeast of Independence.

Catawba Valley Pottery describes alkaline glazed stoneware made in the Catawba River Valley of Western North Carolina from the early 19th century, as well as certain contemporary pottery made in the region utilizing traditional methods and forms.

Dorchester Pottery Works is a historic site at 101-105 Victory Road in Dorchester, Massachusetts, a neighborhood of Boston. The Dorchester Pottery Works was founded in 1895 by George Henderson and made stoneware. The Dorchester Pottery Works closed in 1979. The building was designated as a Boston Landmark in 1980 and added to the National Register of Historic Places in 1985.

Ceramics in Mexico date back thousands of years before the Pre-Columbian period, when ceramic arts and pottery crafts developed with the first advanced civilizations and cultures of Mesoamerica. With one exception, pre-Hispanic wares were not glazed, but rather burnished and painted with colored fine clay slips. The potter's wheel was unknown as well; pieces were shaped by molding, coiling and other methods,

Ceramic art is art made from ceramic materials, including clay. It may take varied forms, including artistic pottery, including tableware, tiles, figurines and other sculpture. As one of the plastic arts, ceramic art is a visual art. While some ceramics are considered fine art, such as pottery or sculpture, most are considered to be decorative, industrial or applied art objects. Ceramic art can be created by one person or by a group, in a pottery or a ceramic factory with a group designing and manufacturing the artware.

George William Newman Fulton (1834–1894) was a noted potter who worked in Allegheny County, Virginia and in Fincastle, Virginia.

References

- 1 2 3 4 5 6 7 8 9 10 11 12 Schmeer, Blaine (1987). Pottery on the Willamette. Halcyon Publications. ISBN 0-9617654-0-2.

- 1 2 3 Corning, Howard McKinley (1973). Willamette Landings. Oregon Historical Society Press. ISBN 0875950426.

- 1 2 3 4 Gaston, Joseph (1911). Portland, Oregon, Its History and Builders: In Connection with the Antecedent Explorations, Discoveries, and Movements of the Pioneers that Selected the Site for the Great City of the Pacific. S.J. Clarke Publishing Company. pp. 279–282.

- ↑ Orheritage (August 3, 2020). "Smith's Oregon Pottery Company". Heritage Museum Society. Retrieved February 2, 2022.

- ↑ "Buena Vista Pottery" (PDF). Heritage Museum Society. Fall 2016. p. 4.

- 1 2 "Willamette Clay: Bricks, homewares, art featured in Corvallis exhibit". Newspapers.com. March 31, 1989. Retrieved February 2, 2022.