The Rammelsberg is a mountain, 635 metres (2,083 ft) high, on the northern edge of the Harz range, south of the historic town of Goslar in the North German state of Lower Saxony. The mountain is the location of an important silver, copper, and lead mine. When it closed in 1988, it had been the only mine still working continuously for over 1,000 years. Because of its long history of mining and testimony to the advancement and exchange of technology over many centuries, the visitor mine of Rammelsberg was inscribed as a UNESCO World Heritage Site in 1992.

The Comstock Lode is a lode of silver ore located under the eastern slope of Mount Davidson, a peak in the Virginia Range in Virginia City, Nevada, which was the first major discovery of silver ore in the United States and named after American miner Henry Comstock.

The Southeast Missouri Lead District, commonly called the Lead Belt, is a lead mining district in the southeastern part of Missouri. Counties in the Lead Belt include Saint Francois, Crawford, Dent, Iron, Madison, Reynolds, and Washington. This mining district is the most important and critical lead producer in the United States.

Mount Isa Mines Limited ("MIM") operates the Mount Isa copper, lead, zinc and silver mines near Mount Isa, Queensland, Australia as part of the Glencore group of companies. For a brief period in 1980, MIM was Australia's largest company. It has pioneered several significant mining industry innovations, including the Isa Process copper refining technology, the Isasmelt smelting technology, and the IsaMill fine grinding technology, and it also commercialized the Jameson Cell column flotation technology.

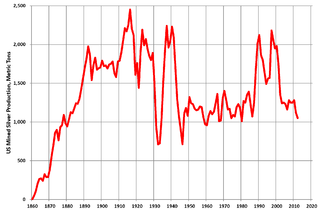

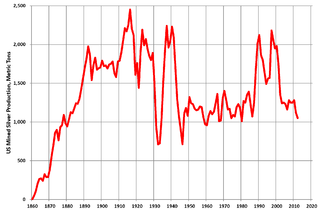

Silver mining in the United States began on a major scale with the discovery of the Comstock Lode in Nevada in 1858. The industry suffered greatly from the demonetization of silver in 1873 by the Coinage Act of 1873, known pejoratively as the "Crime of 73", but silver mining continues today.

Silver mining in Colorado has taken place since the 1860s. In the past, Colorado called itself the Silver State.

Silver mining in Nevada, a state of the United States, began in 1858 with the discovery of the Comstock Lode, the first major silver-mining district in the United States. Nevada calls itself the "Silver State." Nevada is the nation's second-largest producer of silver, after Alaska. In 2014 Nevada produced 10.93 million troy ounces of silver, of which 6.74 million ounces were as a byproduct of the mining of gold. The largest byproducers were the Hycroft Mine, the Phoenix Mine, the Midas Mine and Round Mountain.

The Broken Hill Ore Deposit is located underneath Broken Hill in western New South Wales, Australia, and is the namesake for the town. It is arguably the world's richest and largest zinc-lead ore deposit.

Gold mining in Alaska, a state of the United States, has been a major industry and impetus for exploration and settlement since a few years after the United States acquired the territory in 1867 from the Russian Empire. Russian explorers discovered placer gold in the Kenai River in 1848, but no gold was produced. Gold mining started in 1870 from placers southeast of Juneau, Alaska.

The Leadville mining district, located in the Colorado Mineral Belt, was the most productive silver-mining district in the state of Colorado and hosts one of the largest lead-zinc-silver deposits in the world. Oro City, an early Colorado gold placer mining town located about a mile east of Leadville in California Gulch, was the location to one of the richest placer gold strikes in Colorado, with estimated gold production of 120,000–150,000 ozt, worth $2.5 to $3 million at the then-price of $20.67 per troy ounce.

The Admiralty mining district is a mining area in the U.S. state of Alaska which consists of Admiralty Island. Silver and base metals are mined, with gold recovered as a by-product.

Ophir is an unincorporated community in the north-central part of Montgomery County, North Carolina, United States.

Sala Silver Mine is a mine in Sala Municipality, in Västmanland County in Sweden. The mine was in continuous production from the 15th century until 1908. Additional mining occurred in 1950–1951 and also in 1945–1962 in the neighbouring Bronäs Mine.

Hecla Mining is a gold, silver, and other precious metals mining company based in Coeur d'Alene, Idaho. Founded in 1891, it is the second-largest mining company that produces silver in the country. This area is known as the Silver Valley (Idaho). In 1983, this entire area was designated as a Superfund site by the Environmental Protection Agency, because of land, water, and air contamination resulting from a century of mostly unregulated silver and gold mining.

East Wheal Rose was a metalliferous mine around three-quarters of a mile (1.2 km) south east of the village of St Newlyn East and is around 4 miles (6.4 km) from Newquay on the north Cornwall coast, United Kingdom. The country rock at the mine was killas and its main produce was lead ore (galena), but as is usual when mining this mineral, commercial quantities of silver and zinc were also found and sold.

Mining in the Upper Harz region of central Germany was a major industry for several centuries, especially for the production of silver, lead, copper, and, latterly, zinc as well. Great wealth was accumulated from the mining of silver from the 16th to the 19th centuries, as well as from important technical inventions. The centre of the mining industry was the group of seven Upper Harz mining towns of Clausthal, Zellerfeld, Sankt Andreasberg, Wildemann, Grund, Lautenthal und Altenau.

The Cantonnier lode formed in the Piégut-Pluviers Granodiorite, part of the basement rocks of the northwestern Massif Central in France. Its importance is highlighted by very rare mineral parageneses.

The le Puy Mine is an ancient lead mine in the northwestern Massif Central, France. The mine produced mainly silver-bearing galena.

The Lucky Friday mine is an underground silver, lead, and zinc mine in the western United States, near Mullan, Idaho. Operated by Hecla Mining company, it is one of the few mines remaining operational in the Silver Valley of northern Idaho, producing 1000 tons of ore per day. The ore deposit type is Polymetallic veins of hydrothermal origin. The mining method used is underhand cut and fill mining.

Mount Garnet Mine Assay Office is a heritage-listed assay office at Zinc Road, Mount Garnet, Tablelands Region, Queensland, Australia. It was built from 1899 to 1900. It was added to the Queensland Heritage Register on 21 October 1992.