Filtration is a physical separation process that separates solid matter and fluid from a mixture using a filter medium that has a complex structure through which only the fluid can pass. Solid particles that cannot pass through the filter medium are described as oversize and the fluid that passes through is called the filtrate. Oversize particles may form a filter cake on top of the filter and may also block the filter lattice, preventing the fluid phase from crossing the filter, known as blinding. The size of the largest particles that can successfully pass through a filter is called the effective pore size of that filter. The separation of solid and fluid is imperfect; solids will be contaminated with some fluid and filtrate will contain fine particles. Filtration occurs both in nature and in engineered systems; there are biological, geological, and industrial forms.

Decantation is a process for the separation of mixtures of immiscible liquids or of a liquid and a solid mixture such as a suspension. The layer closer to the top of the container—the less dense of the two liquids, or the liquid from which the precipitate or sediment has settled out—is poured off, leaving the other component or the denser liquid of the mixture behind. An incomplete separation is witnessed during the separation of two immiscible liquids. To put it in a simple way, decantation is separating immiscible materials by transferring the top layer to another container. The process does not provide accurate or pure product.

Centrifugation is a mechanical process which involves the use of the centrifugal force to separate particles from a solution according to their size, shape, density, medium viscosity and rotor speed. The denser components of the mixture migrate away from the axis of the centrifuge, while the less dense components of the mixture migrate towards the axis. Chemists and biologists may increase the effective gravitational force of the test tube so that the precipitate (pellet) will travel quickly and fully to the bottom of the tube. The remaining liquid that lies above the precipitate is called a supernatant or supernate.

In chemistry, a suspension is a heterogeneous mixture of a fluid that contains solid particles sufficiently large for sedimentation. The particles may be visible to the naked eye, usually must be larger than one micrometer, and will eventually settle, although the mixture is only classified as a suspension when and while the particles have not settled out.

Hydrocyclones are a type of cyclonic separators that separate product phases mainly on basis of differences in gravity with aqueous solutions as the primary feed fluid.

Cyclonic separation is a method of removing particulates from an air, gas or liquid stream, without the use of filters, through vortex separation. When removing particulate matter from liquid, a hydrocyclone is used; while from gas, a gas cyclone is used. Rotational effects and gravity are used to separate mixtures of solids and fluids. The method can also be used to separate fine droplets of liquid from a gaseous stream.

Industrial wastewater treatment describes the processes used for treating wastewater that is produced by industries as an undesirable by-product. After treatment, the treated industrial wastewater may be reused or released to a sanitary sewer or to a surface water in the environment. Some industrial facilities generate wastewater that can be treated in sewage treatment plants. Most industrial processes, such as petroleum refineries, chemical and petrochemical plants have their own specialized facilities to treat their wastewaters so that the pollutant concentrations in the treated wastewater comply with the regulations regarding disposal of wastewaters into sewers or into rivers, lakes or oceans. This applies to industries that generate wastewater with high concentrations of organic matter, toxic pollutants or nutrients such as ammonia. Some industries install a pre-treatment system to remove some pollutants, and then discharge the partially treated wastewater to the municipal sewer system.

Sand filters are used as a step in the water treatment process of water purification.

Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy. Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling.

A fluidized bed is a physical phenomenon that occurs when a solid particulate substance is under the right conditions so that it behaves like a fluid. The usual way to achieve a fluidized bed is to pump pressurized fluid into the particles. The resulting medium then has many properties and characteristics of normal fluids, such as the ability to free-flow under gravity, or to be pumped using fluid technologies.

A dust collector is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas. Designed to handle high-volume dust loads, a dust collector system consists of a blower, dust filter, a filter-cleaning system, and a dust receptacle or dust removal system. It is distinguished from air purifiers, which use disposable filters to remove dust.

The physical process of sedimentation has applications in water treatment, whereby gravity acts to remove suspended solids from water. Solid particles entrained by the turbulence of moving water may be removed naturally by sedimentation in the still water of lakes and oceans. Settling basins are ponds constructed for the purpose of removing entrained solids by sedimentation. Clarifiers are tanks built with mechanical means for continuous removal of solids being deposited by sedimentation; however, clarification does not remove dissolved solids.

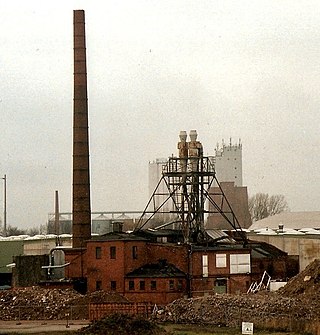

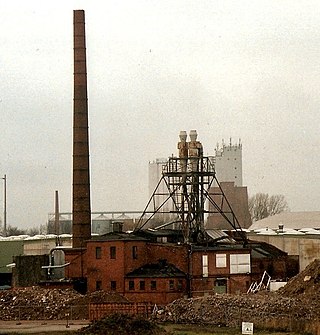

A coal preparation plant is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or ships.

Clarifiers are settling tanks built with mechanical means for continuous removal of solids being deposited by sedimentation. A clarifier is generally used to remove solid particulates or suspended solids from liquid for clarification and/or thickening. Inside the clarifier, solid contaminants will settle down to the bottom of the tank where it is collected by a scraper mechanism. Concentrated impurities, discharged from the bottom of the tank, are known as sludge, while the particles that float to the surface of the liquid are called scum.

Depth filters are filters that use a porous filtration medium to retain particles throughout the medium, rather than just on the surface of the medium. Depth filtration, typified by multiple porous layers with depth, is used to capture the solid contaminants from the liquid phase. These filters are commonly used when the fluid to be filtered contains a high load of particles because, relative to other types of filters, they can retain a large mass of particles before becoming clogged.

A separation process is a method that converts a mixture or a solution of chemical substances into two or more distinct product mixtures, a scientific process of separating two or more substance in order to obtain purity. At least one product mixture from the separation is enriched in one or more of the source mixture's constituents. In some cases, a separation may fully divide the mixture into pure constituents. Separations exploit differences in chemical properties or physical properties between the constituents of a mixture.

Gyratory equipment, used in mechanical screening and sieving is based on a circular motion of the machine. Unlike other methods, gyratory screen operates in a gentler manner and is more suited to handle fragile things, enabling it to produce finer products. This method is applicable for both wet and dry screening.

A conical plate centrifuge is a type of centrifuge that has a series of conical discs which provides a parallel configuration of centrifugation spaces.

An oil water separator (OWS) is a piece of equipment used to separate oil and water mixtures into their separate components. There are many different types of oil-water separator. Each has different oil separation capability and are used in different industries. Oil water separators are designed and selected after consideration of oil separation performance parameters and life cycle cost considerations. "Oil" can be taken to mean mineral, vegetable and animal oils, and the many different hydrocarbons.

Gravity filtration is a method of filtering impurities from solutions by using gravity to pull liquid through a filter. The two main kinds of filtration used in laboratories are gravity and vacuum/suction. Gravity filtration is often used in chemical laboratories to filter precipitates from precipitation reactions as well as drying agents, inadmissible side items, or remaining reactants. While it can also be used to separate out strong products, vacuum filtration is more commonly used for this purpose.