This article needs additional citations for verification .(May 2011) (Learn how and when to remove this template message) |

The black clamp connects to the battery -, the red clamp to +, the green one to the breaker side of the coil (for RPM), the big black clamp in the foreground is an inductive pick-up that clamps around a spark plug wire.

A timing light is a stroboscope used to dynamically set the ignition timing of an Otto cycle or similar internal combustion engine equipped with a distributor. Modern electronically controlled passenger vehicle engines require use of a scan tool to display ignition timing.

A stroboscope also known as a strobe, is an instrument used to make a cyclically moving object appear to be slow-moving, or stationary. It consists of either a rotating disk with slots or holes or a lamp such as a flashtube which produces brief repetitive flashes of light. Usually the rate of the stroboscope is adjustable to different frequencies. When a rotating or vibrating object is observed with the stroboscope at its vibration frequency, it appears stationary. Thus stroboscopes are also used to measure frequency.

In a spark ignition internal combustion engine, Ignition timing refers to the timing, relative to the current piston position and crankshaft angle, of the release of a spark in the combustion chamber near the end of the compression stroke.

An Otto cycle is an idealized thermodynamic cycle that describes the functioning of a typical spark ignition piston engine. It is the thermodynamic cycle most commonly found in automobile engines.

The timing light is connected to the ignition circuit and used to illuminate the timing marks on the engine's crankshaft pulley or flywheel, with the engine running. The apparent position of the marks, frozen by the stroboscopic effect, indicates the current timing of the spark in relation to piston position. A reference pointer is attached to the flywheel housing or other fixed point, and an engraved scale gives the offset between the spark time and the top dead centre position of the piston in the cylinder. The distributor can be rotated slightly until the reference pointer aligns with the specified point on the timing scale.

A timing mark is an indicator used for setting the timing of the ignition system of an engine, typically found on the crankshaft pulley or the flywheel, being the largest radius rotating at crankshaft speed and therefore the place where marks at one degree intervals will be farthest apart.

A crankshaft—related to crank—is a mechanical part able to perform a conversion between reciprocating motion and rotational motion. In a reciprocating engine, it translates reciprocating motion of the piston into rotational motion; whereas in a reciprocating compressor, it converts the rotational motion into reciprocating motion. In order to do the conversion between two motions, the crankshaft has "crank throws" or "crankpins", additional bearing surfaces whose axis is offset from that of the crank, to which the "big ends" of the connecting rods from each cylinder attach.

A flywheel is a mechanical device specifically designed to efficiently store rotational energy. Flywheels resist changes in rotational speed by their moment of inertia. The amount of energy stored in a flywheel is proportional to the square of its rotational speed. The way to change a flywheel's stored energy is by increasing or decreasing its rotational speed by applying a torque aligned with its axis of symmetry,

Fuel-injected engines, or engines with microprocessor controls may require special procedures to allow basic spark timing to be observed without control effects from the engine computer. On most automotive engines, the timing is set based on the #1 cylinder. [1] In few cases an engine is timed off another cylinder, such as the International Harvester V8 engines, which use #8, and the Isuzu 4Z series four-cylinder, which is timed off the #4 cylinder, or the 3 cylinder Saab two-stroke engine which is timed on the middle (#2) cylinder.

The International Harvester Company was a United States manufacturer of agricultural machinery, construction equipment, trucks, automobiles, and household and commercial products. Its reorganized successor, after spin-off of several of those businesses, is Navistar International.

The first Saab two-stroke engine was based on a DKW design. The SAAB engine, a two-cylinder with 764 cc engine displacement and 25 hp was transversally placed in the 1950 - 1956 Saab 92, giving it a top speed of 100 km/h (62 mph). With the 1954 model engine output was raised to 28 hp (21 kW). It had some features only found in modern cars such as one ignition coil per cylinder.

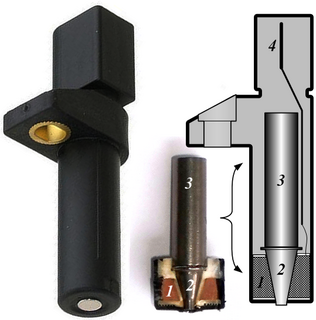

Simple timing lights may just contain a neon lamp operated by the energy provided by the ignition circuit. Timing lights using xenon strobe lamps electronically triggered by the spark provide brighter light, allowing use of the timing lamp under normal shop lighting or daylight conditions.

A neon lamp is a miniature gas discharge lamp. The lamp typically consists of a small glass capsule that contains a mixture of neon and other gases at a low pressure and two electrodes. When sufficient voltage is applied and sufficient current is supplied between the electrodes, the lamp produces an orange glow discharge. The glowing portion in the lamp is a thin region near the cathode; the larger and much longer neon signs are also glow discharges, but they use the positive column which is not present in the ordinary neon lamp. Neon glow lamps are widely used as indicator lamps in the displays of electronic instruments and appliances.

A timing light may be a self-contained instrument, but is sometimes combined with a voltmeter, RPM meter, and a dwell angle meter, or may be incorporated into a more comprehensive instrument such as an engine analyser. Self-contained units used to time automotive engines have an inductive pickup that clamps around the proper spark plug wire and serves as the trigger for the strobe. Power for the strobe comes directly from the vehicle's battery. Some older timing lights require the removal of the spark plug boot in order to attach a direct pickup between the wire's terminal and the centre conductor of the spark plug.

A voltmeter is an instrument used for measuring electrical potential difference between two points in an electric circuit. Analog voltmeters move a pointer across a scale in proportion to the voltage of the circuit; digital voltmeters give a numerical display of voltage by use of an analog to digital converter.

Revolutions per minute is the number of turns in one minute. It is a unit of rotational speed or the frequency of rotation around a fixed axis.

A contact breaker is a type of electrical switch, and the term typically refers to the switching device found in the distributor of the ignition systems of spark-ignition internal combustion engines.