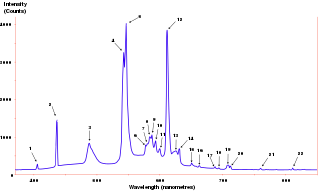

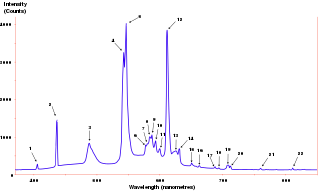

The power spectrum of a time series describes the distribution of power into frequency components composing that signal. According to Fourier analysis, any physical signal can be decomposed into a number of discrete frequencies, or a spectrum of frequencies over a continuous range. The statistical average of a certain signal or sort of signal as analyzed in terms of its frequency content, is called its spectrum.

In materials science, fatigue is the initiation and propagation of cracks in a material due to cyclic loading. Once a fatigue crack has initiated, it grows a small amount with each loading cycle, typically producing striations on some parts of the fracture surface. The crack will continue to grow until it reaches a critical size, which occurs when the stress intensity factor of the crack exceeds the fracture toughness of the material, producing rapid propagation and typically complete fracture of the structure.

Modal testing is the form of vibration testing of an object whereby the natural (modal) frequencies, modal masses, modal damping ratios and mode shapes of the object under test are determined.

Seismic analysis is a subset of structural analysis and is the calculation of the response of a building structure to earthquakes. It is part of the process of structural design, earthquake engineering or structural assessment and retrofit in regions where earthquakes are prevalent.

Structural health monitoring (SHM) involves the observation and analysis of a system over time using periodically sampled response measurements to monitor changes to the material and geometric properties of engineering structures such as bridges and buildings.

A structural load or structural action is a force, deformation, or acceleration applied to structural elements. A load causes stress, deformation, and displacement in a structure. Structural analysis, a discipline in engineering, analyzes the effects of loads on structures and structural elements. Excess load may cause structural failure, so this should be considered and controlled during the design of a structure. Particular mechanical structures—such as aircraft, satellites, rockets, space stations, ships, and submarines—are subject to their own particular structural loads and actions. Engineers often evaluate structural loads based upon published regulations, contracts, or specifications. Accepted technical standards are used for acceptance testing and inspection.

This is an alphabetical list of articles pertaining specifically to structural engineering. For a broad overview of engineering, please see List of engineering topics. For biographies please see List of engineers.

Structural dynamics is a type of structural analysis which covers the behavior of a structure subjected to dynamic loading. Dynamic loads include people, wind, waves, traffic, earthquakes, and blasts. Any structure can be subjected to dynamic loading. Dynamic analysis can be used to find dynamic displacements, time history, and modal analysis.

Modal analysis is the study of the dynamic properties of systems in the frequency domain. Examples would include measuring the vibration of a car's body when it is attached to a shaker, or the noise pattern in a room when excited by a loudspeaker.

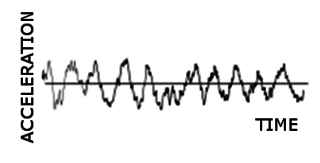

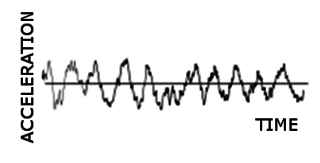

In mechanical engineering, random vibration is motion which is non-deterministic, meaning that future behavior cannot be precisely predicted. The randomness is a characteristic of the excitation or input, not the mode shapes or natural frequencies. Some common examples include an automobile riding on a rough road, wave height on the water, or the load induced on an airplane wing during flight. Structural response to random vibration is usually treated using statistical or probabilistic approaches. Mathematically, random vibration is characterized as an ergodic and stationary process.

The Extreme Response Spectrum (ERS) is defined as a curve giving the value of the highest peak of the response of a linear Single Degree of Freedom System to vibration, according to its natural frequency, for a given damping ratio. The response is described here by the relative movement of the mass of this system in relation to its support. The x-axis refers to the natural frequency and the y-axis to the highest peak multiplied by the square of the quantity, by analogy with the relative displacement shock response spectrum.

In geophysics, geology, civil engineering, and related disciplines, seismic noise is a generic name for a relatively persistent vibration of the ground, due to a multitude of causes, that is often a non-interpretable or unwanted component of signals recorded by seismometers.

Vibratory Stress Relief, often abbreviated VSR, is a non-thermal stress relief method used by the metal working industry to enhance the dimensional stability and mechanical integrity of castings, forgings, and welded components, chiefly for two categories of these metal workpieces:

Ambient modal identification, also known as operational modal analysis (OMA), aims at identifying the modal properties of a structure based on vibration data collected when the structure is under its operating conditions, i.e., no initial excitation or known artificial excitation. The modal properties of a structure include primarily the natural frequencies, damping ratios and mode shapes. In an ambient vibration test the subject structure can be under a variety of excitation sources which are not measured but are assumed to be 'broadband random'. The latter is a notion that one needs to apply when developing an ambient identification method. The specific assumptions vary from one method to another. Regardless of the method used, however, proper modal identification requires that the spectral characteristics of the measured response reflect the properties of the modes rather than those of the excitation.

Bayesian operational modal analysis (BAYOMA) adopts a Bayesian system identification approach for operational modal analysis (OMA). Operational modal analysis aims at identifying the modal properties of a constructed structure using only its (output) vibration response measured under operating conditions. The (input) excitations to the structure are not measured but are assumed to be 'ambient'. In a Bayesian context, the set of modal parameters are viewed as uncertain parameters or random variables whose probability distribution is updated from the prior distribution to the posterior distribution. The peak(s) of the posterior distribution represents the most probable value(s) (MPV) suggested by the data, while the spread of the distribution around the MPV reflects the remaining uncertainty of the parameters.

Low cycle fatigue has two fundamental characteristics: plastic deformation in each cycle; and low cycle phenomenon, in which the materials have finite endurance for this type of load. The term cycle refers to repeated applications of stress that lead to eventual fatigue and failure; low-cycle pertains to a long period between applications.

Solder fatigue is the mechanical degradation of solder due to deformation under cyclic loading. This can often occur at stress levels below the yield stress of solder as a result of repeated temperature fluctuations, mechanical vibrations, or mechanical loads. Techniques to evaluate solder fatigue behavior include finite element analysis and semi-analytical closed-form equations.

Fatigue of welded joints can occur when poorly made or highly stressed welded joints are subjected to cyclic loading. Welding is a manufacturing method used to join various materials in order to form an assembly. During welding, joints are formed between two or more separate pieces of material which can introduce defects or residual stresses. Under cyclic loading these defects can grow a fatigue crack, causing the assembly to fail even if these cyclic stresses are low and smaller than the base material and weld filler material yield stress. Hence, the fatigue strength of a welded joint does not correlate to the fatigue strength of the base material. Incorporating design considerations in the development phase can reduce failures due to fatigue in welded joints.

Fatigue testing is a specialised form of mechanical testing that is performed by applying cyclic loading to a coupon or structure. These tests are used either to generate fatigue life and crack growth data, identify critical locations or demonstrate the safety of a structure that may be susceptible to fatigue. Fatigue tests are used on a range of components from coupons through to full size test articles such as automobiles and aircraft.

Fastran is a computer program for calculating the rate of fatigue crack growth by combining crack growth equations and a simulation of the plasticity at the crack tip.