The straight-five engine is a piston engine with five cylinders mounted in a straight line along the crankshaft.

The Volvo PV is a series of two-door, four-passenger car models — the PV444 and the PV544 — made by Volvo from 1947 to 1965. During World War II's early stages, Volvo decided that a new, smaller car that could deliver good fuel economy would assure the company's future. A raw materials shortage during the war drove home the point that an automobile should be smaller, and also complicated Volvo's ability to mass-produce the product. In 1944, when the car was finally introduced to a car-hungry public, response was very positive and orders poured in from the Swedish population. It was another three years though, until 1947, before series production began.

The Volvo Sport is a Swedish fiberglass-bodied roadster of which sixty-eight units were built, first 19 by Glasspar Company in California, between 1956 and 1957 by Volvo Cars.

The Chrysler B and RB engines are a series of big-block V8 gasoline engines introduced in 1958 to replace the Chrysler FirePower engines. The B and RB engines are often referred to as "wedge" engines because they use wedge-shaped combustion chambers; this differentiates them from Chrysler's 426 Hemi big block engines that are typically referred to as "Hemi" or "426 Hemi" due to their hemispherical shaped combustion chambers. The corporation had been seeking a smaller and lighter replacement for its FirePower engines, in part because new styling dictates meant moving the engine forward in the chassis which negatively affected weight distribution.

The LA engine is a family of overhead-valve small-block 90° V-configured gasoline engines built by Chrysler Corporation between 1964 and 2003. Primarily V8s, the line includes a single V6 and V10, both derivations of its Magnum series introduced in 1992. A replacement of the Chrysler A engine, they were factory-installed in passenger vehicles, trucks and vans, commercial vehicles, marine and industrial applications. Their combustion chambers are wedge-shaped, rather than polyspheric, as in the A engine, or hemispheric in the Chrysler Hemi. LA engines have the same 4.46 in (113 mm) bore spacing as the A engines.

The Chevrolet small-block engine is a series of gasoline-powered V8 automobile engines, produced by the Chevrolet division of General Motors between 1954 and 2003, using the same basic engine block. Referred to as a "small-block" for its size relative to the physically much larger Chevrolet big-block engines, the small-block family spanned from 262 cu in (4.3 L) to 400 cu in (6.6 L) in displacement. Engineer Ed Cole is credited with leading the design for this engine. The engine block and cylinder heads were cast at Saginaw Metal Casting Operations in Saginaw, Michigan.

The Iron Duke engine is a 151 cu in (2.5 L) straight-4 piston engine built by the Pontiac Motor Division of General Motors from 1977 until 1993. Originally developed as Pontiac's new economy car engine, it was used in a wide variety of vehicles across GM's lineup in the 1980s as well as supplied to American Motors Corporation (AMC). The engine was engineered for fuel efficiency, smooth operation, and long life, not for performance. Total Duke engine production is estimated to be between 3.8 and 4.2 million units.

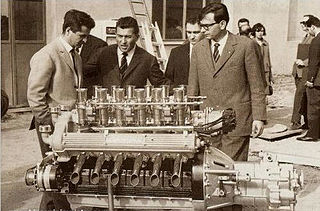

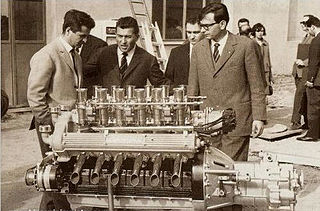

The Lamborghini V12 refers to the flagship V12 engine used by Lamborghini. Lamborghini has had two generations of V12 engines through their history, both of which were developed in-house. The first-generation Lamborghini V12 was a sixty degree (60°) V12 petrol engine designed by Lamborghini, and was the first internal combustion engine ever produced by the firm.

The E-series was a line of inline four-cylinder automobile engines designed and built by Honda for use in their cars in the 1970s and 1980s. These engines were notable for the use of CVCC technology, introduced in the ED1 engine in the 1975 Civic, which met 1970s emissions standards without using a catalytic converter.

The Austin Motor Company A-series is a British small straight-4 automobile engine. Launched in 1951 with the Austin A30, production lasted until 2000 in the Mini. It used a cast-iron block and cylinder head, and a steel crankshaft with three main bearings. The camshaft ran in the cylinder block, driven by a single-row chain for most applications, and with tappets sliding in the block, accessible through pressed steel side covers for most applications, and with overhead valves operated through rockers. The cylinder blocks are not interchangeable between versions intended for conventional end-on mounted gearboxes and the 'in-sump' transaxle used on British Motor Corporation/British Leyland front wheel drive models such as the Mini. The cylinder head for the overhead-valve version of the A-series engine was designed by Harry Weslake – a cylinder head specialist famed for his involvement in SS (Jaguar) engines and several Formula One-title winning engines. Although a "clean sheet" design, the A-series owed much to established Austin engine design practise, resembling in general design and overall appearance a scaled-down version of the 1200cc overhead-valve engine first seen in the Austin A40 Devon which would form the basis of the later B-series engine.

The Nissan L series of automobile engines was produced from 1966 through 1986 in both inline-four and inline-six configurations ranging from 1.3 L to 2.8 L. It is a two-valves per cylinder SOHC non-crossflow engine, with an iron block and an aluminium head. It was most notable as the engine of the Datsun 510, Datsun 240Z sports car, and the Nissan Maxima. These engines are known for their reliability, durability, and parts interchangeability.

Manifold vacuum, or engine vacuum in a petrol engine is the difference in air pressure between the engine's intake manifold and Earth's atmosphere.

The Volvo B21 is a slanted straight-four engine first used in the Volvo 200 series, meant to replace the B20. The B21 and all derived engines are often referred to as red block engines for the red paint applied to the block. The primary differences when compared to the B20 was the switch to a SOHC in place of the older pushrod configuration, and an aluminum crossflow cylinder head versus the iron head of the B20.

Carburetor heat is a system used in automobile and piston-powered light aircraft engines to prevent or clear carburetor icing. It consists of a moveable flap which draws hot air into the engine intake. The air is drawn from the heat stove, a metal plate around the exhaust manifold.

The Saab two-stroke was a two-stroke cycle, inline, two cylinder, and later three cylinder engine manufactured by Swedish automotive manufacturer Saab that was based on a design by German manufacturer DKW.

The Subaru EA engine is a series of automobile internal combustion engines manufactured by Subaru, a division of Fuji Heavy Industries. All EA series engines are of a flat-4 design, and have always been water cooled.

F Renault engine is an automotive internal combustion engine, four-stroke, inline-four engine bored directly into the iron block, water cooled, with overhead camshaft driven by a timing belt, and with an aluminum cylinder head, developed and produced by Renault in the early '80s, making its appearance on the Renault 9 and 11. This engine is available in petrol and diesel versions, with 8 or 16 valves.

Renix was a joint venture by Renault and Bendix that designed and manufactured automobile electronic ignitions, fuel injection systems, electronic automatic transmission controls, and various engine sensors. Major applications included various Renault and Volvo vehicles. The name became synonymous in the U.S. with the computer and fuel injection system used on the AMC/Jeep 2.5 L I4 and 4.0 L I6 engines.