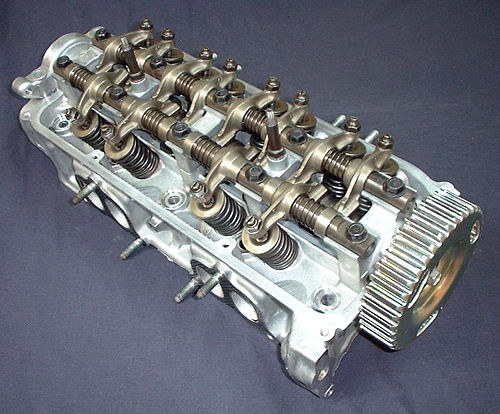

In a piston engine, the cylinder head sits above the cylinders, [1] forming the roof of the combustion chamber. In sidevalve engines the head is a simple plate of metal containing the spark plugs and possibly heat dissipation fins. In more modern overhead valve and overhead camshaft engines, the head is a more complicated metal block that also contains the inlet and exhaust passages, and often coolant passages, valvetrain components, and fuel injectors.