A poppet valve is a valve typically used to control the timing and quantity of petrol (gas) or vapour flow into or out of an engine, but with many other applications.

A camshaft is a shaft that contains a row of pointed cams in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines, mechanically controlled ignition systems and early electric motor speed controllers.

In a piston engine, the cylinder head sits above the cylinders, forming the roof of the combustion chamber. In sidevalve engines the head is a simple plate of metal containing the spark plugs and possibly heat dissipation fins. In more modern overhead valve and overhead camshaft engines, the head is a more complicated metal block that also contains the inlet and exhaust passages, and often coolant passages, Valvetrain components, and fuel injectors.

A desmodromic valve is a reciprocating engine poppet valve that is positively closed by a cam and leverage system, rather than by a more conventional spring.

VTEC is a system developed by Honda to improve the volumetric efficiency of a four-stroke internal combustion engine, resulting in higher performance at high RPM, and lower fuel consumption at low RPM. The VTEC system uses two camshaft profiles and hydraulically selects between profiles. It was invented by Honda engineer Ikuo Kajitani. It is distinctly different from standard VVT systems which change only the valve timings and do not change the camshaft profile or valve lift in any way.

An overhead camshaft (OHC) engine is a piston engine in which the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combustion chamber in the engine block.

Redline refers to the maximum engine speed at which an internal combustion engine or traction motor and its components are designed to operate without causing damage to the components themselves or other parts of the engine. The redline of an engine depends on various factors such as stroke, mass of the components, displacement, composition of components, and balance of components.

An overhead valve (OHV) engine, sometimes called a pushrod engine, is a piston engine whose valves are located in the cylinder head above the combustion chamber. This contrasts with flathead engines, where the valves were located below the combustion chamber in the engine block.

A flathead engine, also known as a sidevalve engine or valve-in-block engine, is an internal combustion engine with its poppet valves contained within the engine block, instead of in the cylinder head, as in an overhead valve engine.

A tappet or valve lifter is a valve train component which converts rotational motion into linear motion in activating a valve. It is most commonly found in internal combustion engines, where it converts the rotational motion of the camshaft into linear motion of intake and exhaust valves, either directly or indirectly.

Valve float is an adverse condition which can occur at high engine speeds when the poppet valves in an internal combustion engine valvetrain do not properly follow the closure phase of the cam lobe profile. This reduces engine efficiency and performance. There is also a significant risk of severe engine damage that can include valve spring failure, pistons contacting the valves, or catastrophic lifter and cam lobe failure, especially with roller lifters.

The Honda F-Series engine was considered Honda's "big block" SOHC inline four, though lower production DOHC versions of the F-series were built. It features a solid iron or aluminum open deck cast iron sleeved block and aluminum/magnesium cylinder head.

A valvetrain is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture into the combustion chamber, while the exhaust valves control the flow of spent exhaust gases out of the combustion chamber once combustion is completed.

A hydraulic tappet, also known as a hydraulic valve lifter or hydraulic lash adjuster, is a device for maintaining zero valve clearance in an internal combustion engine. Conventional solid valve lifters require regular adjusting to maintain a small clearance between the valve and its rocker or cam follower. This space prevents the parts from binding as they expand with the engine's heat, but can also lead to noisy operation and increased wear as the parts rattle against one another until they reach operating temperature. The hydraulic lifter was designed to compensate for this small tolerance, allowing the valve train to operate with zero clearance—leading to quieter operation, longer engine life, and eliminating the need for periodic adjustment of valve clearance.

The intake/inlet over exhaust, or "IOE" engine, known in the US as F-head, is a four-stroke internal combustion engine whose valvetrain comprises OHV inlet valves within the cylinder head and exhaust side-valves within the engine block.

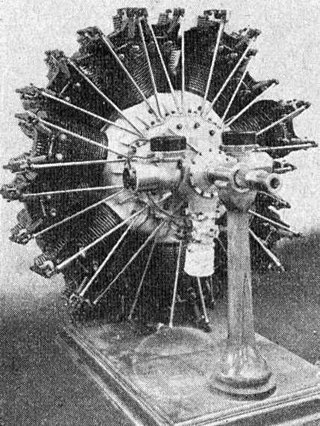

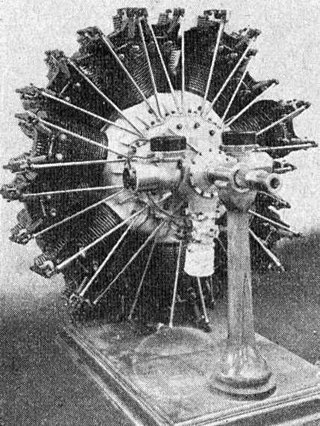

The Lorraine 9N Algol was a French 9-cylinder radial aeroengine built and used in the 1930s. It was rated at up to 370 kW (500 hp), but more usually in the 220–300 kW (300–400 hp) range.

The Lorraine 14A Antarès was a French 14-cylinder radial aero engine built and used in the 1930s. It was rated in the 370 kW (500 hp) range.

The Maybach VL I was an Otto cycle V-12 engine, made from 1924 in Germany. The airship LZ 126 was powered by five VL I engines which emphasised reliability and low fuel consumption.