An engine or motor is a machine designed to convert one or more forms of energy into mechanical energy.

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be transformed, by a connecting rod and crank, into rotational force for work. The term "steam engine" is generally applied only to reciprocating engines as just described, not to the steam turbine. Steam engines are external combustion engines, where the working fluid is separated from the combustion products. The ideal thermodynamic cycle used to analyze this process is called the Rankine cycle. In general usage, the term steam engine can refer to either complete steam plants, such as railway steam locomotives and portable engines, or may refer to the piston or turbine machinery alone, as in the beam engine and stationary steam engine.

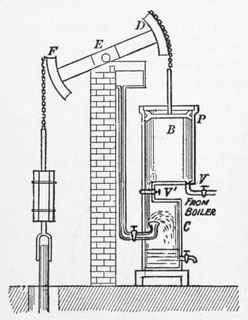

The atmospheric engine was invented by Thomas Newcomen in 1712, and is often referred to simply as a Newcomen engine. The engine was operated by condensing steam drawn into the cylinder, thereby creating a partial vacuum which allowed the atmospheric pressure to push the piston into the cylinder. It was the first practical device to harness steam to produce mechanical work. Newcomen engines were used throughout Britain and Europe, principally to pump water out of mines. Hundreds were constructed throughout the 18th century.

An alternator is an electrical generator that converts mechanical energy to electrical energy in the form of alternating current. For reasons of cost and simplicity, most alternators use a rotating magnetic field with a stationary armature. Occasionally, a linear alternator or a rotating armature with a stationary magnetic field is used. In principle, any AC electrical generator can be called an alternator, but usually the term refers to small rotating machines driven by automotive and other internal combustion engines.

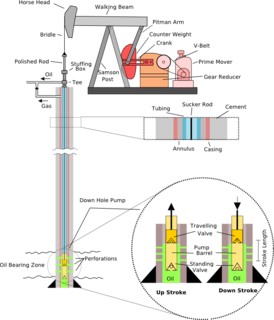

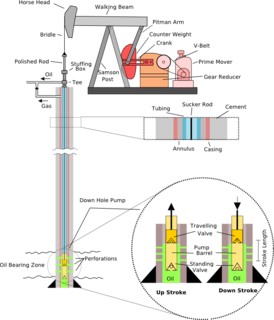

A pumpjack is the overground drive for a reciprocating piston pump in an oil well.

A stationary engine is an engine whose framework does not move. They are used to drive immobile equipment, such as pumps, generators, mills or factory machinery, or cable cars. The term usually refers to large immobile reciprocating engines, principally stationary steam engines and, to some extent, stationary internal combustion engines. Other large immobile power sources, such as steam turbines, gas turbines, and large electric motors, are categorized separately.

Stationary steam engines are fixed steam engines used for pumping or driving mills and factories, and for power generation. They are distinct from locomotive engines used on railways, traction engines for heavy steam haulage on roads, steam cars, agricultural engines used for ploughing or threshing, marine engines, and the steam turbines used as the mechanism of power generation for most nuclear power plants.

Improvements to the steam engine were some of the most important technologies of the Industrial Revolution.., although steam did not replace water power in importance in Britain until after the Industrial Revolution. From Englishman Thomas Newcomen's atmospheric engine, of 1712, through major developments by Scottish inventor and mechanical engineer James Watt, the steam engine began to be used in many industrial settings, not just in mining, where the first engines had been used to pump water from deep workings. Early mills had run successfully with water power, but by using a steam engine a factory could be located anywhere, not just close to a water source. Water power varied with the seasons and was not always available.

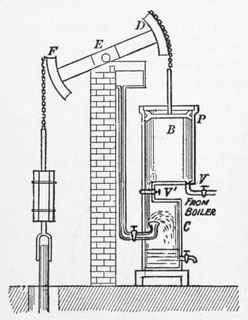

A beam engine is a type of steam engine where a pivoted overhead beam is used to apply the force from a vertical piston to a vertical connecting rod. This configuration, with the engine directly driving a pump, was first used by Thomas Newcomen around 1705 to remove water from mines in Cornwall. The efficiency of the engines was improved by engineers including James Watt, who added a separate condenser; Jonathan Hornblower and Arthur Woolf, who compounded the cylinders; and William McNaught, who devised a method of compounding an existing engine. Beam engines were first used to pump water out of mines or into canals but could be used to pump water to supplement the flow for a waterwheel powering a mill.

A Corliss steam engine is a steam engine, fitted with rotary valves and with variable valve timing patented in 1849, invented by and named after the American engineer George Henry Corliss of Providence, Rhode Island.

Haigh Foundry was an ironworks and foundry in Haigh, Lancashire, which was notable for the manufacture of early steam locomotives.

A Cornish engine is a type of steam engine developed in Cornwall, England, mainly for pumping water from a mine. It is a form of beam engine that uses steam at a higher pressure than the earlier engines designed by James Watt. The engines were also used for powering man engines to assist the underground miners' journeys to and from their working levels, for winching materials into and out of the mine, and for powering on-site ore stamping machinery.

A man engine is a mechanism of reciprocating ladders and stationary platforms installed in mines to assist the miners' journeys to and from the working levels. It was invented in Germany in the 19th century and was a prominent feature of tin and copper mines in Cornwall until the beginning of the twentieth century.

The first recorded rudimentary steam engine was the aeolipile described by Heron of Alexandria in 1st-century Roman Egypt. Several steam-powered devices were later experimented with or proposed, such as Taqi al-Din's steam jack, a steam turbine in 16th-century Ottoman Egypt, and Thomas Savery's steam pump in 17th-century England. In 1712, Thomas Newcomen's atmospheric engine became the first commercially successful engine using the principle of the piston and cylinder, which was the fundamental type of steam engine used until the early 20th century. The steam engine was used to pump water out of coal mines.

Prestongrange Museum is an industrial heritage museum at Prestongrange between Musselburgh and Prestonpans on the B1348 on the East Lothian coast, Scotland. Founded as the original site of the National Mining Museum, its operation reverted to East Lothian Council Museum Service in 1992.

A water-returning engine was an early form of stationary steam engine, developed at the start of the Industrial Revolution in the middle of the 18th century. The first beam engines did not generate power by rotating a shaft but were developed as water pumps, mostly for draining mines. By coupling this pump with a water wheel, they could be used to drive machinery.

A semi-portable engine is a form of stationary steam engine. They were built in a factory as a single unit including the boiler, so that they could be rapidly installed on site and brought into service.

A house-built engine is a stationary steam engine that is built into an engine house, such that it uses the masonry of the engine house as an integral part of the support of the engine.

A cataract was a speed governing device used for early single-acting beam engines, particularly atmospheric engines and Cornish engines. It was a kind of water clock.

Six-column beam engines are a type of beam engine, where the beam's central pivot is supported on a cast-iron frame or 'bedstead', supported on six iron columns.