A thermoplastic, or thermosoftening plastic, is a plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

Polycarbonates (PC) are a group of thermoplastic polymers containing carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, tough materials, and some grades are optically transparent. They are easily worked, molded, and thermoformed. Because of these properties, polycarbonates find many applications. Polycarbonates do not have a unique resin identification code (RIC) and are identified as "Other", 7 on the RIC list. Products made from polycarbonate can contain the precursor monomer bisphenol A (BPA).

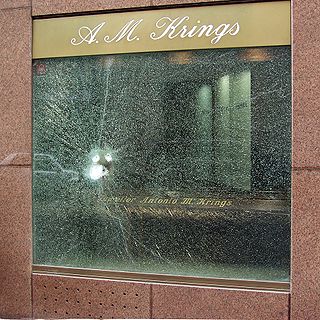

Bulletproof glass, ballistic glass, transparent armor, or bullet-resistant glass is a strong and optically transparent material that is particularly resistant to penetration by projectiles. Like any other material, it is not completely impenetrable. It is usually made from a combination of two or more types of glass, one hard and one soft. The softer layer makes the glass more elastic, so that it can flex instead of shatter. The index of refraction for both of the glasses used in the bulletproof layers must be almost the same to keep the glass transparent and allow a clear, undistorted view through the glass. Bulletproof glass varies in thickness from 3⁄4 to 3+1⁄2 inches.

A refractory material or refractory is a material that is resistant to decomposition by heat, pressure, or chemical attack, and retains strength and form at high temperatures. Refractories are polycrystalline, polyphase, inorganic, non-metallic, porous, and heterogeneous. They are typically composed of oxides or non oxides like carbides, nitrides etc. of the following materials: silicon, aluminium, magnesium, calcium, and zirconium. Some metals with melting points >1850 °C like niobium, chromium, zirconium, tungsten, rhenium, tantalum, molybdenum etc. are also considered refractories.

Heat-shrink tubing is a shrinkable plastic tube used to insulate wires, providing abrasion resistance and environmental protection for stranded and solid wire conductors, connections, joints and terminals in electrical work. It can also be used to repair the insulation on wires or to bundle them together, to protect wires or small parts from minor abrasion, and to create cable entry seals, offering environmental sealing protection. Heat-shrink tubing is ordinarily made of polyolefin, which shrinks radially when heated, to between one-half and one-sixth of its diameter.

An electrical enclosure is a cabinet for electrical or electronic equipment to mount switches, knobs and displays and to prevent electrical shock to equipment users and protect the contents from the environment. The enclosure is the only part of the equipment which is seen by users. It may be designed not only for its utilitarian requirements, but also to be pleasing to the eye. Regulations may dictate the features and performance of enclosures for electrical equipment in hazardous areas, such as petrochemical plants or coal mines. Electronic packaging may place many demands on an enclosure for heat dissipation, radio frequency interference and electrostatic discharge protection, as well as functional, esthetic and commercial constraints.

Structural steel is a category of steel used for making construction materials in a variety of shapes. Many structural steel shapes take the form of an elongated beam having a profile of a specific cross section. Structural steel shapes, sizes, chemical composition, mechanical properties such as strengths, storage practices, etc., are regulated by standards in most industrialized countries.

FKM is a family of fluorocarbon-based fluoroelastomer materials defined by the ASTM International standard D1418, while it is called FPM by ISO 1629. It is commonly called fluorine rubber or fluoro-rubber. All FKMs contain vinylidene fluoride as a monomer. Originally developed by DuPont, FKMs are today also produced by many companies, including: Daikin (Dai-El), 3M (Dyneon), Solvay S.A. (Tecnoflon), HaloPolymer (Elaftor), Gujarat Fluorochemicals (Fluonox), Zrunek (ZruElast), and several Chinese manufacturers including VSK Industrial. Fluoroelastomers are more expensive than neoprene or nitrile rubber elastomers. They provide additional heat and chemical resistance. FKMs can be divided into different classes on the basis of either their chemical composition, their fluorine content, or their cross-linking mechanism.

Tempered or toughened glass is a type of safety glass processed by controlled thermal or chemical treatments to increase its strength compared with normal glass. Tempering puts the outer surfaces into compression and the interior into tension. Such stresses cause the glass, when broken, to shatter into small granular chunks instead of splintering into jagged shards as ordinary annealed glass does. The granular chunks are less likely to cause injury.

The SAE steel grades system is a standard alloy numbering system for steel grades maintained by SAE International.

ASTM A53 is a carbon steel alloy, used as structural steel or for low-pressure plumbing. The alloy specifications are set by ASTM International, in specification ASTM A53/A53M.

6061 is a precipitation-hardened aluminium alloy, containing magnesium and silicon as its major alloying elements. Originally called "Alloy 61S", it was developed in 1935. It has good mechanical properties, exhibits good weldability, and is very commonly extruded. It is one of the most common alloys of aluminum for general-purpose use.

ASTM E2395 is a Standard Specification for Voluntary Security Performance of Window and Door Assemblies with and without Glazing Impact. This standard was created by the American Standard for Testing and Materials (ASTM). ASTM International which was funded in 1898, is an international standards developing organization that develops and publishes standards for a wide range of materials, products, systems, and services. Through this standard is specified voluntary performance test for the resistance to forced entry of window and door assemblies. This standards deal with the capability of window and door assemblies to prevent entry about intruders. These requirements are only limited to window and door assemblies

ASTM F1712 is a standard specification for steel chain-link fencing materials used for high security applications. This standard was created by the American Standard for Testing and Materials (ASTM). ASTM International which was founded in 1898, is an international standards developing organization that develops and publishes standards for a wide range of materials, products, systems, and services. This was published by ASTM F14 which is a committee specializes about high security fences and perimeter barriers.

ASTM F2248 is a standard practice for specifying an equivalent 3-Second Duration design loading for blast resistant glazing fabricated with laminated glass. This standard was created by the American Standard for Testing and Materials (ASTM). ASTM International which was founded in 1898, is an international standards developing organization that develops and publishes standards for a wide range of materials, products, systems, and services. This standard was published by ASTM F14 which is a committee specializes about on systems products and services. The standard explain different methods to check the thickness and type of blast resistant glazing fabricated with laminated glass to glaze a fenestration

ASTM F2348 is a standard test performance specification for privacy padlocks. This standard was created by the American Standard for Testing and Materials (ASTM). ASTM International which was funded in 1898, is an international standards developing organization that develops and publishes standards for a wide range of materials, products, systems, and services. This standard was published by ASTM F12.50 which is a committee specializes about locking devices. The standards deal with requirement regarding security for padlocks. This standard involves descriptions, operational tests, forcing tests, and surreptitious entry tests.

Bituminous waterproofing systems are designed to protect residential and commercial buildings. Bitumen is a mixed substance made up of organic liquids that are highly sticky, viscous, and waterproof. These systems are sometimes used to construct roofs, in the form of roofing felt or roll roofing products.

Package testing or packaging testing involves the measurement of a characteristic or property involved with packaging. This includes packaging materials, packaging components, primary packages, shipping containers, and unit loads, as well as the associated processes.

Polyetherketoneketone (PEKK) is a semi-crystalline thermoplastic in the polyaryletherketone (PAEK) family of polymers. It possesses high heat, chemical, and mechanical load resistance. PEKK has a glass transition temperature (Tg) of 162°C.

2219 aluminium alloy is an alloy in the wrought aluminium-copper family. It can be heat-treated to produce tempers with higher strength but lower ductility. The aluminium-copper alloys have high strength, but are generally less corrosion resistant and harder to weld than other types of aluminium alloys. To compensate for the lower corrosion resistance, 2219 aluminium can be clad in a commercially pure alloy such as 1050 or painted. This alloy is commonly formed by both extrusion and forging, but is not used in casting.