Lead glass, commonly called crystal, is a variety of glass in which lead replaces the calcium content of a typical potash glass. Lead glass contains typically 18–40% lead(II) oxide (PbO), while modern lead crystal, historically also known as flint glass due to the original silica source, contains a minimum of 24% PbO. Lead glass is often desirable for a variety of uses due to its clarity. In marketing terms it is often called crystal glass.

Pressed glass is a form of glass made by pressing molten glass into a mold using a plunger. Although hand pressed glass has existed for over 1,000 years, the use of a machine for pressing was first patented by Pittsburgh glass man John P. Bakewell in 1825 to make knobs for furniture.

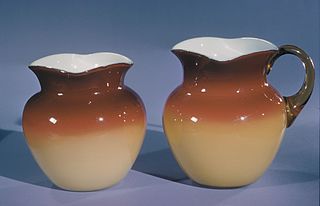

Depression glass is glassware made in the period 1929–1939, often clear or colored translucent machine-made glassware that was distributed free, or at low cost, in the United States and Canada around the time of the Great Depression. Depression glass is so called because collectors generally associate mass-produced glassware in pink, yellow, crystal, green, and blue with the Great Depression in America.

The early modern period in England brought on a revival in local glass production. Medieval glass had been limited to the small-scale production of forest glass for window glass and vessels, predominantly in the Weald. The organisation of production evolved from the small-scale family-run glass houses typical of forest glass-making to large monopolies granted by the Crown. The influx of immigrants from Europe brought changes in furnace technology and raw materials, creating a better quality glass. Monastic decrees later banned the use of wood fuel which was then replaced by the less expensive alternative of coal. The development of lead glass in the late 17th century propelled England to the forefront of the glass industry and paved the way for advancements in the Industrial Revolution.

The Fostoria Glass Company was a manufacturer of pressed, blown and hand-molded glassware and tableware. It began operations in Fostoria, Ohio, on December 15, 1887, on land donated by the townspeople. The new company was formed by men from West Virginia who were experienced in the glassmaking business. They started their company in northwest Ohio to take advantage of newly discovered natural gas that was an ideal fuel for glassmaking. Numerous other businesses were also started in the area, and collectively they depleted the natural gas supply. Fuel shortages caused the company to move to Moundsville, West Virginia, in 1891.

The Sneath Glass Company was an American manufacturer of glass and glassware. After a brief 1890s startup in Tiffin, Ohio, the company moved to Hartford City, Indiana, to take advantage of the Indiana Gas Boom. The small city was enjoying the benefits of the boom, and could provide natural gas as an energy source for manufacturers. Sneath Glass was one of many glass manufacturers that moved to the region, and became Hartford City's second largest employer.

Belmont Glass Company, also known as the Belmont Glass Works, was one of Ohio's early glassmaking companies. It was named after Belmont County, Ohio, where the plant was located. The firm began operations in 1866 in a riverfront village along the east side of the county, which is known as Bellaire. At that time, the community had resource advantages that made it an attractive site for glassmaking. Bellaire's location at the intersection of the Ohio River, the National Road, and two railroads meant it had an excellent transportation infrastructure. Fuel necessary for the glassmaking process was also readily available, since Belmont County was part of the eastern Ohio coal region. Bellaire also had a workforce with glassmaking expertise located less than five miles away, since glass had been produced in Wheeling, West Virginia, since the 1820s.

The Macbeth-Evans Glass Company was an American glass company that created "almost every kind of glass for illuminating, industrial and scientific purposes," but is today famous for making depression glass.

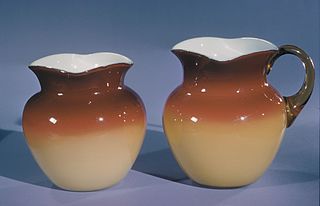

Early American molded glass refers to glass functional and decorative objects, such as bottles and dishware, that were manufactured in the United States in the 19th century. The objects were produced by blowing molten glass into a mold, thereby causing the glass to assume the shape and pattern design of the mold. When a plunger rather than blowing is used, as became usual later, the glass is technically called pressed glass. Common blown molded tableware items bearing designs include salt dishes, sugar bowls, creamers, celery stands, decanters, and drinking glasses.

Seneca Glass Company was a glass manufacturer that began in Fostoria, Ohio, in 1891. At one time it was the largest manufacturer of blown tumblers in the United States. The company was also known for its high-quality lead (crystal) stemware, which was hand-made for nearly a century. Customers included Eleanor Roosevelt and Lyndon B. Johnson, and retailers such as Marshall Field and Company, Neiman Marcus, and Tiffany's.

Early glassmaking in the United States began in Colonial America in 1608 at the Colony of Virginia near Jamestown, believed to be the first industrial facility in what would later become the United States. For centuries, glassmaking procedures, techniques, and recipes were kept secret, with countries actively preventing glassmaking knowledge from spreading beyond their borders. German workers with glassmaking knowledge, described as Dutchmen, along with Polish glass workers, were brought to Colonial America to begin operations. Although glass was made at Jamestown, production was soon suspended because of strife in the colony. A second attempt at Jamestown also failed.

J. H. Hobbs, Brockunier and Company was one of the largest and best-known manufacturers of glass in the United States during the 19th century. Its products were distributed worldwide. The company is responsible for one of the greatest innovations in American glassmaking—an improved formula for lime glass that enabled American glass manufacturers to produce high-quality glass at a lower cost. The firm also developed talented glassmakers that started glass factories in Ohio and Indiana.

Indiana Glass Company was an American company that manufactured pressed, blown and hand-molded glassware and tableware for almost 100 years. Predecessors to the company began operations in Dunkirk, Indiana, in 1896 and 1904, when East Central Indiana experienced the Indiana gas boom. The company started in 1907, when a group of investors led by Frank W. Merry formed a company to buy the Dunkirk glass plant that belonged to the bankrupt National Glass Company. National Glass was a trust for glass tableware that originally owned 19 glass factories including the plant in Dunkirk. National Glass went bankrupt in 1907, and its assets were sold in late 1908.

The Nickel Plate Glass Company was a manufacturer of tableware, lamps, and bar goods. It began operations in Fostoria, Ohio, on August 8, 1888, on land donated by the townspeople. The new company was formed by men from West Virginia who were experienced in the glassmaking business, and their company was incorporated in that state in February of the same year. They were lured to northwest Ohio to take advantage of newly discovered natural gas that was an ideal low-cost fuel for glassmaking. The company name came from the New York, Chicago and St. Louis Railroad, commonly known as the "Nickel Plate Road", which had tracks adjacent to the new glass plant.

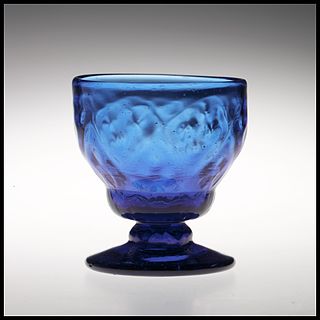

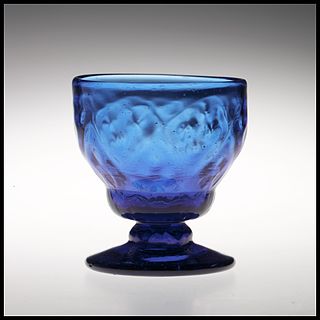

18th century glassmaking in the United States began before the country existed. During the previous century, several attempts were made to produce glass, but none were long-lived. By 1700, it is thought that little or no glass was being produced in the British colonies that would eventually become the United States. The first American glass factory operated with long–term success was started by Caspar Wistar in 1745—although two glass works in New Amsterdam that operated in the previous century deserve honorable mention. Wistar's glass works was located in the English colony known as the Province of New Jersey. In the southeastern portion of the Province of Pennsylvania, Henry Stiegel was the first American producer of high–quality glassware known as crystal. Stiegel's first glass works began in 1763, and his better quality glassmaking began in 1769. In the United States, the first use of coal as a fuel for glassmaking furnaces is believed to have started in 1794 at a short-lived factory on the Schuylkill River near Philadelphia. In 1797 Pittsburgh's O'Hara and Craig glass works was also powered by coal, and it contributed to the eventual establishment of Pittsburgh as a leading glassmaking center in the 19th century.

Very few 19th Century glassmaking innovations in the United States happened at the beginning of the century. Only ten glass manufacturers are thought to have been operating in 1800. High-quality glassware was imported from England, and glassmaking knowledge was kept secret. England controlled a key ingredient for producing high–quality glassware and kept its price high—making it difficult for American glass manufacturers to compete price-wise. European glassmakers with the knowledge to produce high–quality glassware were, in some cases, smuggled to the United States. Eventually the American glass industry grew, and the second half of the century saw numerous innovations.

19th century glass categories in the United States include types of glass and decoration methods for glass. A simplified category version appropriate at the beginning of the century is glassware, bottles, and windows. As the century progressed, glass production became more complex and made necessary more categories and subcategories. An 1884 United States government report used glassware, bottles, windows, and plate glass as major categories—although plate glass accounted for only four percent of the value of all glass made.

19th century glassmaking in the United States started slowly with less than a dozen glass factories operating. Much of the nation's better quality glass was imported, and English glassmakers had a monopoly on major ingredients for high–quality glass such as good–quality sand and red lead. A tariff and the War of 1812 added to the difficulties of making crystal glass in America. After the war, English glassmakers began dumping low priced glassware in the United States, which caused some glass works to go out of business. A protective tariff and the ingenuity of Boston businessman Deming Jarves helped revive the domestic glass industry.

Bakewell, Pears and Company was Pittsburgh's best known glass manufacturer. The company was most famous for its lead crystal glass, which was often decorated by cutting or engraving. It also made window glass, bottles, and lamps. The company was one of the first American glass manufacturers to produce glass using mechanical pressing. In the 1820s and 1830s, Bakewell glassware was purchased for the White House by presidents James Monroe and Andrew Jackson. Founder Benjamin Bakewell is considered by some to be father of the crystal glassware business in the United States.

Sulphide portrait glassware is blown, cut, and molded glassware usually made from lead crystal that encases an image. The image appears silver or white, as if made from silver sulphide. Although sulphide is used to describe glass decorated in this manor, the silver or white image is actually a hardened clay paste. Experiments with this glass decorating style began in Europe during the late 18th century, and processes for production were successfully implemented in France and England during the early 19th century. Production in the United States began in the 1820s.