Related Research Articles

A differential is a gear train with three drive shafts that has the property that the rotational speed of one shaft is the average of the speeds of the others. A common use of differentials is in motor vehicles, to allow the wheels at each end of a drive axle to rotate at different speeds while cornering. Other uses include clocks and analog computers.

A traction control system (TCS), is typically a secondary function of the electronic stability control (ESC) on production motor vehicles, designed to prevent loss of traction of the driven road wheels. TCS is activated when throttle input and engine power and torque transfer are mismatched to the road surface conditions.

Four-wheel drive, also called 4×4 or 4WD, refers to a two-axled vehicle drivetrain capable of providing torque to all of its wheels simultaneously. It may be full-time or on-demand, and is typically linked via a transfer case providing an additional output drive shaft and, in many instances, additional gear ranges.

A limited-slip differential (LSD) is a type of differential that allows its two output shafts to rotate at different speeds but limits the maximum difference between the two shafts. Limited-slip differentials are often known by the generic trademark Positraction, a brand name owned by General Motors and originally used for its Chevrolet branded vehicles.

Quattro is the trademark used by the automotive brand Audi to indicate that all-wheel drive (AWD) technologies or systems are used on specific models of its automobiles.

In automotive design, a front-engine, front-wheel-drive (FWD) layout, or FF layout, places both the internal combustion engine and driven roadwheels at the front of the vehicle.

A transfer case is a part of the drivetrain of four-wheel-drive, all-wheel-drive, and other multiple powered axle vehicles. The transfer case transfers power from the transmission to the front and rear axles by means of drive shafts. It also synchronizes the difference between the rotation of the front and rear wheels(only high-speed 4wd-Awd systems), and may contain one or more sets of low range gears for off-road use.

A locking differential is a mechanical component, commonly used in vehicles, designed to overcome the chief limitation of a standard open differential by essentially "locking" both wheels on an axle together as if on a common shaft. This forces both wheels to turn in unison, regardless of the traction available to either wheel individually.

The Ford Expedition is a full-size three-row SUV, manufactured by Ford. Introduced for the 1997 model year as the successor of the Ford Bronco, the Expedition was the first full-size Ford SUV sold with a four-door body. For its entire production life, the Ford Expedition has been derived from the corresponding generation of the Ford F-150 in production, sharing some body and mechanical components. The fourth-generation Ford Expedition began production for the 2018 model year. Similar to the configuration of the Chevrolet Tahoe and Suburban, the Ford Expedition is sold in regular and extended lengths ; sold since 2007, the latter functionally serves as the replacement for the Ford Excursion.

4Matic is the marketing name of an all-wheel drive system developed by Mercedes-Benz. It is designed to increase traction in slippery conditions. With the introduction of the 2017 E 63 S sedan, Mercedes-AMG announced a performance-oriented variant of the system called AMG Performance 4MATIC+.

BMW xDrive is the marketing name for the all-wheel drive system found on various BMW models since 2003. The system uses an electronically actuated clutch-pack differential to vary the torque between the front and rear axles. Models with the DPC torque vectoring system also have a planetary gearset to overdrive an axle or rear wheel as required.

ATTESA is a four-wheel drive system used in some automobiles produced by the Japanese automaker Nissan, including some models under its luxury marque Infiniti.

Jeep uses a variety of four-wheel drive systems on their vehicles. These range from basic part-time systems that require the driver to move a control lever to send power to four wheels, to permanent four-wheel systems that monitor and sense traction needs at all four wheels automatically under all conditions.

Super Handling-All Wheel Drive (SH-AWD) is a full-time, fully automatic, all-wheel drive traction and handling system, which combines front-rear torque distribution control with independently regulated torque distribution to the left and right rear wheels. This way the system freely distributes the optimum amount of torque to all four wheels according to the driving conditions." The system was announced in April 2004, and was introduced in the North American market in the second generation 2005 model year Acura RL, and in Japan as the fourth generation Honda Legend.

Super Select is the brand name of a four-wheel drive system produced by Mitsubishi Motors, used worldwide except for North America, where it was initially known as Active-Trac. It was first introduced in 1991 with the then-new second generation of the Mitsubishi Pajero.

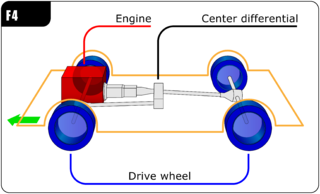

In automotive design, an F4, or front-engine, four-wheel drive (4WD) layout places the internal combustion engine at the front of the vehicle and drives all four roadwheels. This layout is typically chosen for better control on many surfaces, and is an important part of rally racing, as well as off-road driving. In terms of racing purposes, whether it be on-road or off-road, can be described as follows,

A team that pursues the Weak LS4WD architecture will minimize the development cost of the front-wheel drive system at the expense of having a larger rear powertrain. The Weak architecture produces a vehicle with a large powersplit between the front and rear powertrains, while the Strong architecture recommends a vehicle with more similar power and torque requirements for the front and rear.

S-AWC is the brand name of an advanced full-time four-wheel drive system developed by Mitsubishi Motors. The technology, specifically developed for the new 2007 Lancer Evolution, the 2010 Outlander, the 2014 Outlander, the Outlander PHEV and the Eclipse Cross have an advanced version of Mitsubishi Motors' AWC system. Mitsubishi Motors first exhibited S-AWC integration control technology in the Concept-X model at the 39th Tokyo Motor Show in 2005. According to Mitsubishi Motors, "the ultimate embodiment of the company's AWC philosophy is the S-AWC system, a 4WD-based integrated vehicle dynamics control system".

All Wheel Control (AWC) is the brand name of a four-wheel drive (4WD) system developed by Mitsubishi Motors. The system was first incorporated in the 2001 Lancer Evolution VII. Subsequent developments have led to S-AWC (Super All Wheel Control), developed specifically for the new 2007 Lancer Evolution. The system is referred by the company as its unique 4-wheel drive technology umbrella, cultivated through its motor sports activities and long history in rally racing spanning almost half a century.

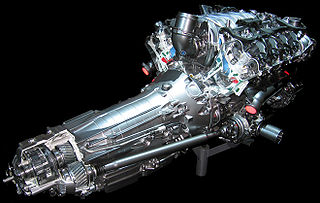

A drivetrain is the group of components that deliver mechanical power from the prime mover to the driven components. In automotive engineering, the drivetrain is the components of a motor vehicle that deliver power to the drive wheels. This excludes the engine or motor that generates the power. In marine applications, the drive shaft will drive a propeller, thruster, or waterjet rather than a drive axle, while the actual engine might be similar to an automotive engine. Other machinery, equipment and vehicles may also use a drivetrain to deliver power from the engine(s) to the driven components.

The Symmetrical All-Wheel Drive is a full-time four-wheel drive system developed by the Japanese automobile manufacturer Subaru. The SAWD system consists of a longitudinally mounted boxer engine coupled to a symmetrical drivetrain with equal length half-axles. The combination of the symmetrical layout with a flat engine and a transmission balanced over the front axle provides optimum weight distribution with low center of gravity, improving the steering characteristics of the vehicle. Ever since 1986, most of the Subaru models sold in the international market are equipped with the SAWD system by default, with the rear wheel drive BRZ and kei cars as the exceptions.

References

- 1 2 3 4 5 6 7 8 9 10 11 12 13 14 "4-wheel drive steps back to the future". www.designnews.com. Retrieved 2012-09-10.

- 1 2 3 "New Ford Expedition Features Borg-Warner Transfer Case". www.thefreelibrary.com. Retrieved 2012-09-11.

- ↑ "BorgWarner Products". www.borgwarner.com. Retrieved 2012-09-10.

- 1 2 3 "Control Trac® delivers automatic torque split, low-range". www.ford-trucks.com. Retrieved 2012-09-10.

- ↑ "2011 Ford Explorer Overview". www.ford-trucks.com. Retrieved 2012-09-10.

- ↑ "Intelligent 4WD". www.ford.com. Retrieved 2012-09-10.

- 1 2 3 4 5 "2003 Ford Expedition Overview". www.ford-trucks.com. Retrieved 2012-09-10.

- 1 2 3 4 "2002 Ford Explorer Overview/Powertrain". www.ford-trucks.com. Retrieved 2012-09-10.