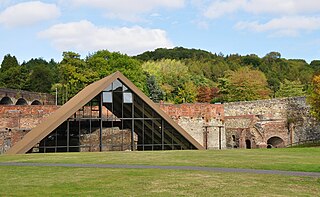

Dyfi Furnace is a restored mid 18th century charcoal fired blast furnace used for smelting iron ore. It has given its name to the adjoining hamlet of Furnace (Welsh : Ffwrnais).

Dyfi Furnace is a restored mid 18th century charcoal fired blast furnace used for smelting iron ore. It has given its name to the adjoining hamlet of Furnace (Welsh : Ffwrnais).

The Dyfi Furnace is in the village of Furnace, Ceredigion, Wales, adjoining the A487 trunk road from Machynlleth to Aberystwyth, near Eglwysfach.

The site for Dyfi Furnace was chosen downstream of the waterfall on the River Einion to take advantage of the water power from the river and charcoal produced from the local woodlands, with the iron ore being shipped in from Cumbria via the Afon Dyfi.

The furnace built around 1755 was only used for about fifty years to smelt iron ore. By 1810 it had been abandoned and the waterwheel removed. [1] The etching by John George Wood to accompany his "The Principal Rivers of Wales", published 1813, shows the furnace in its transitional form with no waterwheel attached. Some time later a new waterwheel was installed - the one that has been renovated and is visible today - and the furnace became a sawmill. The furnace site was renovated around 1988. [2]

The furnace was built by Ralph Vernon and the brothers Edward Bridge and William Bridge [ citation needed ]. Vernon retired between 1765 and 1770, and the Bridges (who also owned Conwy Furnace) became bankrupt in 1773. It is likely that the furnace was then transferred to Kendall & Co. [ citation needed ] (Jonathan Kendall and his brother Henry), ironmasters from the West Midlands with extensive interests scattered across Staffordshire, Cheshire, The Lake District and Scotland. After the original lease expired in 1796, it appears [ citation needed ] the furnace was then owned by Bell and Gaskell, including Thomas Bell, who had managed it for the Kendalls, whose main activity by then was running the Beaufort Ironworks in Beaufort, Ebbw Vale, in the South Wales Valleys.

The water wheel, shown in the photographs, provided power for a sawmill. [3]

The site was previously a Silver Mill of the Society of Mines Royal.

| Water wheel |  |  |

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. Blast refers to the combustion air being supplied above atmospheric pressure.

Coalbrookdale is a village in the Ironbridge Gorge in Shropshire, England, containing a settlement of great significance in the history of iron ore smelting. It lies within the civil parish called the Gorge.

The Wealden iron industry was located in the Weald of south-eastern England. It was formerly an important industry, producing a large proportion of the bar iron made in England in the 16th century and most British cannon until about 1770. Ironmaking in the Weald used ironstone from various clay beds, and was fuelled by charcoal made from trees in the heavily wooded landscape. The industry in the Weald declined when ironmaking began to be fuelled by coke made from coal, which does not occur accessibly in the area.

A bloomery is a type of metallurgical furnace once used widely for smelting iron from its oxides. The bloomery was the earliest form of smelter capable of smelting iron. Bloomeries produce a porous mass of iron and slag called a bloom. The mix of slag and iron in the bloom, termed sponge iron, is usually consolidated and further forged into wrought iron. Blast furnaces, which produce pig iron, have largely superseded bloomeries.

Pyrometallurgy is a branch of extractive metallurgy. It consists of the thermal treatment of minerals and metallurgical ores and concentrates to bring about physical and chemical transformations in the materials to enable recovery of valuable metals. Pyrometallurgical treatment may produce products able to be sold such as pure metals, or intermediate compounds or alloys, suitable as feed for further processing. Examples of elements extracted by pyrometallurgical processes include the oxides of less reactive elements like iron, copper, zinc, chromium, tin, and manganese.

The Lehigh Crane Iron Company, later renamed Crane Iron Company, was a major ironmaking firm in the Lehigh Valley from its founding in 1839 until its sale in 1899. It was based in Catasauqua, Pennsylvania, and was founded by Josiah White and Erskine Hazard, who financed its development through their Lehigh Coal & Navigation Company, which promoted the then-novel technique of smelting iron ore with anthracite coal. This was an important cost and energy savings technique, credited with eliminating the need for either expensive charcoal or coke producing processes and transport costs that proved central to the acceleration of the American industrial revolution.

Seend Ironstone Quarry and Road Cutting is a 3 acres (1.2 ha) Geological Site of Special Scientific Interest at Seend in Wiltshire, England, notified in 1965. The site contains facies of Lower Greensand containing specimens of fauna not found elsewhere.

The Katahdin Iron Works is a Maine state historic site located in the unorganized township of the same name. It is the site of an ironworks which operated from 1845 to 1890. In addition to the kilns of the ironworks, the community was served by a railroad and had a 100-room hotel. The site was listed on the National Register of Historic Places in 1969.

Ferrous metallurgy is the metallurgy of iron and its alloys. The earliest surviving prehistoric iron artifacts, from the 4th millennium BC in Egypt, were made from meteoritic iron-nickel. It is not known when or where the smelting of iron from ores began, but by the end of the 2nd millennium BC iron was being produced from iron ores in the region from Greece to India, and sub-Saharan Africa. The use of wrought iron was known by the 1st millennium BC, and its spread defined the Iron Age. During the medieval period, smiths in Europe found a way of producing wrought iron from cast iron, in this context known as pig iron, using finery forges. All these processes required charcoal as fuel.

Cornwall Iron Furnace is a designated National Historic Landmark that is administered by the Pennsylvania Historical and Museum Commission in Cornwall, Lebanon County, Pennsylvania in the United States. The furnace was a leading Pennsylvania iron producer from 1742 until it was shut down in 1883. The furnaces, support buildings and surrounding community have been preserved as a historical site and museum, providing a glimpse into Lebanon County's industrial past. The site is the only intact charcoal-burning iron blast furnace in its original plantation in the western hemisphere. Established by Peter Grubb in 1742, Cornwall Furnace was operated during the Revolution by his sons Curtis and Peter Jr. who were major arms providers to George Washington. Robert Coleman acquired Cornwall Furnace after the Revolution and became Pennsylvania's first millionaire. Ownership of the furnace and its surroundings was transferred to the Commonwealth of Pennsylvania in 1932.

The Oregon Iron Company was an iron smelting company located in what is now Lake Oswego, Oregon. The company was established in 1865, and in 1867, became the first company west of the Rocky Mountains in the United States to smelt iron. The company failed after a few years, but was reorganized as the Oswego Iron Company in 1878, and again as the Oregon Iron and Steel Company in 1883. With the addition of a larger furnace, the last incarnation of the company prospered, reaching peak production in 1890. By 1894, however, pressure from cheaper imported iron combined with the effects of the Panic of 1893 forced the company to close its smelter. The company continued to operate a pipe foundry until 1928, and until the early 1960s, existed as a land management company, selling its real estate holdings which expanded the city of Lake Oswego.

The firm of Harrison Ainslie & Co. was a British firm of ironmasters and iron ore merchants, selling high quality haematite from their mines on Lindal Moor to smelters in Glasgow, Scotland, South Wales and the Midlands. From a 21st-century perspective, they are more interesting as the last operators of charcoal-fired blast furnaces in Great Britain. Their furnaces were stone-built, water-powered, and much smaller than the coke-fired furnaces of the same era.

The Duddon furnace is a surviving charcoal-fuelled blast furnace near Broughton-in-Furness in Cumbria. It is on the west side of the River Duddon in the parish of Millom and formerly in Cumberland.

Old Furnace State Park is a public recreation area adjacent to Ross Pond State Park in the town of Killingly, Connecticut. The state parks covers 367 acres (149 ha), sits at an elevation of 390 feet (120 m), and is open year-round for hiking, hunting, and fishing. It is located east of Interstate 395, south of U.S. Route 6 and north of Connecticut Route 695. The park is the site of a former iron furnace. It was established as a town park in 1909 before being transferred to the state in 1918.

Clarksville Iron Furnace was a charcoal iron furnace in Unicoi County, Tennessee, built in 1833 and operated until 1844. Its ruins are in Cherokee National Forest and are listed on the National Register of Historic Places.

The Bonawe Iron Furnace, was an industrial complex located in Bonawe, Lorn District, Scotland. It operated in the middle of the eighteenth century, with the aim of producing pig iron. Central to this complex was a charcoal fired blast furnace.

The Bogolong iron mine and blast furnace is an abandoned iron mining and smelting site, near Bookham, New South Wales, Australia. Located in an area known best for sheep grazing and wool, it has been called Australia's 'forgotten furnace'. In 1874, the blast furnace produced a small amount of pig iron—sufficient to allow its testing—that was smelted from iron ore mined nearby. Plans to operate commercially did not eventuate. It is significant as one of the only three remaining ruins of 19th-Century iron-smelting blast furnaces in Australia, and the only one in New South Wales.

The Ilfracombe Iron Company (I.I.C.) was an iron mining and smelting company that operated in Northern Tasmania in 1873 and 1874.

The Wundowie charcoal iron and wood distillation plant manufactured pig iron between 1948 and 1981 and wood distillation products between 1950 and 1977, at Wundowie, Western Australia.