The Industrial Revolution, sometimes divided into the First Industrial Revolution and Second Industrial Revolution, was a period of global transition of the human economy towards more widespread, efficient and stable manufacturing processes that succeeded the Agricultural Revolution. Beginning in Great Britain, the Industrial Revolution spread to continental Europe and the United States, from around 1760 to about 1820–1840. This transition included going from hand production methods to machines; new chemical manufacturing and iron production processes; the increasing use of water power and steam power; the development of machine tools; and the rise of the mechanised factory system. Output greatly increased, and the result was an unprecedented rise in population and the rate of population growth. The textile industry was the first to use modern production methods, and textiles became the dominant industry in terms of employment, value of output, and capital invested.

Derwent Valley Mills is a World Heritage Site along the River Derwent in Derbyshire, England, designated in December 2001. It is administered by the Derwent Valley Mills Partnership. The modern factory, or 'mill', system was born here in the 18th century to accommodate the new technology for spinning cotton developed by Richard Arkwright. With advancements in technology, it became possible to produce cotton continuously. The system was adopted throughout the valley, and later spread so that by 1788 there were over 200 Arkwright-type mills in Britain. Arkwright's inventions and system of organising labour was exported to Europe and the United States.

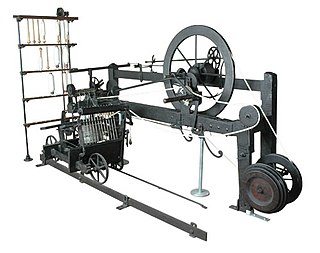

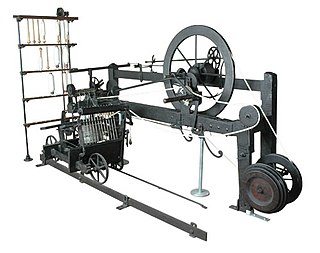

James Hargreaves was an English weaver, carpenter and inventor who lived and worked in Lancashire, England. Hargreaves is credited with inventing the spinning jenny in 1764.

A factory, manufacturing plant or production plant is an industrial facility, often a complex consisting of several buildings filled with machinery, where workers manufacture items or operate machines which process each item into another. They are a critical part of modern economic production, with the majority of the world's goods being created or processed within factories.

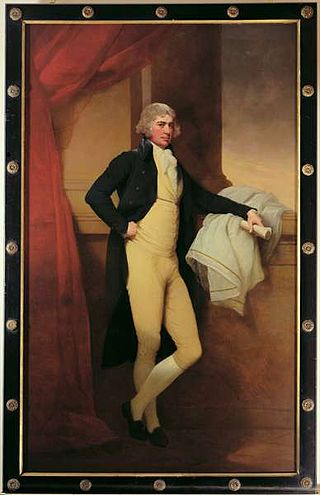

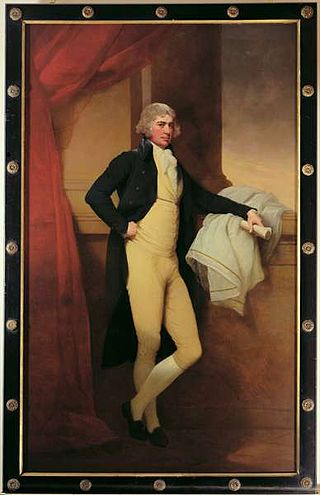

Sir Richard Arkwright was an English inventor and a leading entrepreneur during the early Industrial Revolution. He is credited as the driving force behind the development of the spinning frame, known as the water frame after it was adapted to use water power; and he patented a rotary carding engine to convert raw cotton to 'cotton lap' prior to spinning. He was the first to develop factories housing both mechanised carding and spinning operations.

Samuel Slater was an early English-American industrialist known as the "Father of the American Industrial Revolution", a phrase coined by Andrew Jackson, and the "Father of the American Factory System". In the United Kingdom, he was called "Slater the Traitor" and "Sam the Slate" because he brought British textile technology to the United States, modifying it for American use. He memorized the textile factory machinery designs as an apprentice to a pioneer in the British industry before migrating to the U.S. at the age of 21.

The history of technology is the history of the invention of tools and techniques by humans. Technology includes methods ranging from simple stone tools to the complex genetic engineering and information technology that has emerged since the 1980s. The term technology comes from the Greek word techne, meaning art and craft, and the word logos, meaning word and speech. It was first used to describe applied arts, but it is now used to describe advancements and changes that affect the environment around us.

A cotton mill is a building that houses spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

Textile manufacture during the British Industrial Revolution was centred in south Lancashire and the towns on both sides of the Pennines in the United Kingdom. The main drivers of the Industrial Revolution were textile manufacturing, iron founding, steam power, oil drilling, the discovery of electricity and its many industrial applications, the telegraph and many others. Railroads, steamboats, the telegraph and other innovations massively increased worker productivity and raised standards of living by greatly reducing time spent during travel, transportation and communications.

Improvements to the steam engine were some of the most important technologies of the Industrial Revolution, although steam did not replace water power in importance in Britain until after the Industrial Revolution. From Englishman Thomas Newcomen's atmospheric engine, of 1712, through major developments by Scottish inventor and mechanical engineer James Watt, the steam engine began to be used in many industrial settings, not just in mining, where the first engines had been used to pump water from deep workings. Early mills had run successfully with water power, but by using a steam engine a factory could be located anywhere, not just close to a water source. Water power varied with the seasons and was not always available.

The factory system is a method of manufacturing whereby workers and manufacturing equipment are centralized in a factory, the work is supervised and structured through a division of labor, and the manufacturing process is mechanized. Because of the high capital cost of machinery and factory buildings, factories are typically privately owned by wealthy individuals or corporations who employ the operative labor. Use of machinery with the division of labor reduced the required skill-level of workers and also increased the output per worker.

The spinning frame is an Industrial Revolution invention for spinning thread or yarn from fibres such as wool or cotton in a mechanized way. It was developed in 18th-century Britain by Richard Arkwright and John Kay.

The textile industry is primarily concerned with the design, production and distribution of textiles: yarn, cloth and clothing.

Samuel Oldknow (1756–1828) was an English cotton manufacturer.

A line shaft is a power-driven rotating shaft for power transmission that was used extensively from the Industrial Revolution until the early 20th century. Prior to the widespread use of electric motors small enough to be connected directly to each piece of machinery, line shafting was used to distribute power from a large central power source to machinery throughout a workshop or an industrial complex. The central power source could be a water wheel, turbine, windmill, animal power or a steam engine. Power was distributed from the shaft to the machinery by a system of belts, pulleys and gears known as millwork.

Cotton-spinning machinery is machines which process prepared cotton roving into workable yarn or thread. Such machinery can be dated back centuries. During the 18th and 19th centuries, as part of the Industrial Revolution cotton-spinning machinery was developed to bring mass production to the cotton industry. Cotton spinning machinery was installed in large factories, commonly known as cotton mills.

Thomas Highs (1718–1803), of Leigh, Lancashire, was a reed-maker and manufacturer of cotton carding and spinning engines in the 1780s, during the Industrial Revolution. He is known for claiming patents on a spinning jenny, a carding machine and the throstle.

The productivity-improving technologies are the technological innovations that have historically increased productivity.

Peter Atherton was a British inventor, entrepreneur, and cotton mill proprietor. Renowned for his pioneering work as a designer and manufacturer of textile machinery during the early Industrial Revolution, Atherton began his career by assisting Richard Arkwright and John Kay in developing the ground-breaking spinning frame in the late 1760s. Subsequently, Atherton developed methods to elongate cotton, wool, and silk fibres, resulting in stronger, smoother yarn and finer quality fabrics, representing a notable progression in textile manufacturing. His influence extended to mill construction nationwide, where his innovative designs and use of steam power marked significant advancements in industrial architecture. He engaged with policymakers and advocated for the interests of the British textile industry, notably participating in a delegation that met with Prime Minister William Pitt the Younger in 1788 to safeguard domestic production against the encroachments of the East India Company. Additionally, he established and invested in numerous enterprises within both the textile and clock and watchmaking industries. One of his companies, Atherton & Co., became a leading manufacturer of cotton spinners, with locations in Warrington, Manchester, and Liverpool.