Mason Bogie locomotives are a type of articulated tank locomotive suited for sharp curves and uneven track, once commonly used on narrow-gauge railways in the United States. The design is a development of the Single Fairlie locomotive.

A Fairlie locomotive is a type of articulated steam locomotive that has the driving wheels on bogies. The locomotive may be double-ended or single ended. Most double-ended Fairlies had wheel arrangements of 0-4-4-0T or 0-6-6-0T.

A cotton mill is a building that houses spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

Textile manufacture during the British Industrial Revolution was centred in south Lancashire and the towns on both sides of the Pennines in the United Kingdom. The main drivers of the Industrial Revolution were textile manufacturing, iron founding, steam power, oil drilling, the discovery of electricity and its many industrial applications, the telegraph and many others. Railroads, steamboats, the telegraph and other innovations massively increased worker productivity and raised standards of living by greatly reducing time spent during travel, transportation and communications.

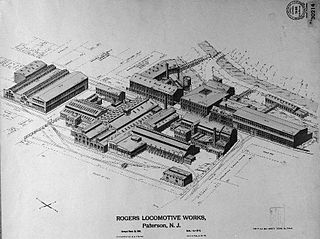

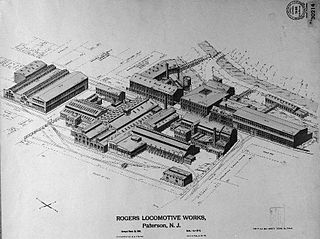

Rogers Locomotive and Machine Works was a manufacturer of railroad steam locomotives based in Paterson, in Passaic County, New Jersey, in the United States. Between its founding in 1832 and its acquisition in 1905, the company built more than 6,000 steam locomotives for railroads around the world. Most 19th-century U.S. railroads owned at least one Rogers-built locomotive. The company's most famous product was a locomotive named The General, built in December 1855, which was one of the principals of the Great Locomotive Chase of the American Civil War.

Matthias William Baldwin was an American inventor and machinery manufacturer, specializing in the production of steam locomotives. Baldwin's small machine shop, established in 1825, grew to become Baldwin Locomotive Works, one of the largest and most successful locomotive manufacturing firms in the United States. The most famous of the early locomotives were Old Ironsides, built by Matthias Baldwin in 1832. Baldwin was also a strong advocate of abolitionism.

Under the Whyte notation for the classification of steam locomotives by wheel arrangement, 2-4-4 is a steam locomotive with two unpowered leading wheels followed by four powered driving wheels and four unpowered trailing wheels. This configuration was only used for tank locomotives; no tender locomotives with this wheel arrangement were made.

Matthew Murray was an English steam engine and machine tool manufacturer, who designed and built the first commercially viable steam locomotive, the twin-cylinder Salamanca in 1812. He was an innovative designer in many fields, including steam engines, machine tools and machinery for the textile industry.

William Mason was a master mechanical engineer and builder of textile machinery and railroad steam locomotives. He founded Mason Machine Works of Taunton, Massachusetts. His company was a significant supplier of locomotives and rifles for the Union Army during the American Civil War. The company also later produced printing presses.

Charles Tillinghast James was a consulting manufacturing engineer, early proponent of steam mills, and United States Democratic Senator from the state of Rhode Island from 1851 to 1857.

The Amoskeag Manufacturing Company was a textile manufacturer which founded Manchester, New Hampshire, United States. From modest beginnings it grew throughout the 19th century into the largest cotton textile plant in the world. At its peak, Amoskeag had 17,000 employees and around 30 buildings.

Platt Brothers, also known as Platt Bros & Co Ltd, was a British company based at Werneth in Oldham, North West England. The company manufactured textile machinery and were iron founders and colliery proprietors. By the end of the 19th century, the company had become the largest textile machinery manufacturer in the world, employing more than 12,000 workers.

Samuel Leonard Crocker was a businessman and U.S. Representative from Taunton, Massachusetts. Crocker graduated from Brown University, Providence, Rhode Island, in 1822. Throughout his life, he engaged in various manufacturing and civic interests in his hometown of Taunton and throughout Massachusetts.

The Whittenton Mills Complex is a historic textile mill site located on Whittenton Street in Taunton, Massachusetts, on the banks of the Mill River. The site has been used for industrial purposes since 1670, when James Leonard built an iron forge on the west bank of the river. The first textile mill was built in 1805 and expanded throughout the 19th century. The complex was added to the National Register of Historic Places in 1984, and now contains various small businesses.

The Taunton Locomotive Manufacturing Company was one of the earliest firms in the United States established especially for the manufacture of steam locomotives. Located in Taunton, Massachusetts, the company was organized in 1849 and incorporated the following year by William A. Crocker, Willard W. Fairbanks, William R. Lee and their associates. Their first engine, the Rough and Ready was delivered in May 1849.

Ring spinning is a spindle-based method of spinning fibres, such as cotton, flax or wool, to make a yarn. The ring frame developed from the throstle frame, which in its turn was a descendant of Arkwright's water frame. Ring spinning is a continuous process, unlike mule spinning which uses an intermittent action. In ring spinning, the roving is first attenuated by using drawing rollers, then spun and wound around a rotating spindle which in its turn is contained within an independently rotating ring flyer. Traditionally ring frames could only be used for the coarser counts, but they could be attended by semi-skilled labour.

William Mason is a 4-4-0 steam locomotive currently on display at the Baltimore and Ohio Railroad Museum in Baltimore, Maryland, United States. It was built for the Baltimore and Ohio Railroad, carrying that railroad's number 25. The locomotive is named in honor of its builder, William Mason, who built around 754 steam locomotives at his Mason Machine Works firm in Taunton, Massachusetts, from 1853 until his death in 1883. The engine had been one of the oldest operable examples of the American Standard design, and is the fourth oldest Baltimore and Ohio locomotive in existence, the oldest being the 0-4-0 no. 2, the Andrew Jackson from 1836, second oldest is the no. 8 0-4-0, John Hancock built later that same year, and the third being the 0-8-0 no. 57, Memnon of 1848. While operable, William Mason had been one of the oldest operational locomotive in the world, and the oldest in the western hemisphere.

Under the Whyte notation for the classification of steam locomotives, 0-6-6 represents the wheel arrangement of no leading wheels, six powered and coupled driving wheels on three axles and six trailing wheels on three axles. All locomotives with this wheel arrangement were tank locomotives; no 0-6-6 tender locomotives were recorded.

Paul Rapsey Hodge was an English-American inventor and mechanical engineer. He invented technological improvements used by railroad companies. He also invented a device that ground wheat and other grains into flour that could then be used by bakers, as well as a machine that turned vegetable pulp into paper that could be used by printers. His innovations were useful to many industries. He was a writer of technical manuals in both the United States and England.