A nickel metal hydride battery is a type of rechargeable battery. The chemical reaction at the positive electrode is similar to that of the nickel–cadmium cell (NiCd), with both using nickel oxide hydroxide (NiOOH). However, the negative electrodes use a hydrogen-absorbing alloy instead of cadmium. NiMH batteries can have two to three times the capacity of NiCd batteries of the same size, with significantly higher energy density, although much less than lithium-ion batteries.

A hybrid vehicle is one that uses two or more distinct types of power, such as submarines that use diesel when surfaced and batteries when submerged. Other means to store energy include pressurized fluid in hydraulic hybrids.

A lithium-ion or Li-ion battery is a type of rechargeable battery which uses the reversible reduction of lithium ions to store energy. The anode of a conventional lithium-ion cell is typically graphite made from carbon. The cathode is typically a metal oxide. The electrolyte is typically a lithium salt in an organic solvent.

A rechargeable battery, storage battery, or secondary cell, is a type of electrical battery which can be charged, discharged into a load, and recharged many times, as opposed to a disposable or primary battery, which is supplied fully charged and discarded after use. It is composed of one or more electrochemical cells. The term "accumulator" is used as it accumulates and stores energy through a reversible electrochemical reaction. Rechargeable batteries are produced in many different shapes and sizes, ranging from button cells to megawatt systems connected to stabilize an electrical distribution network. Several different combinations of electrode materials and electrolytes are used, including lead–acid, zinc–air, nickel–cadmium (NiCd), nickel–metal hydride (NiMH), lithium-ion (Li-ion), lithium iron phosphate (LiFePO4), and lithium-ion polymer.

A lithium polymer battery, or more correctly lithium-ion polymer battery, is a rechargeable battery of lithium-ion technology using a polymer electrolyte instead of a liquid electrolyte. High conductivity semisolid (gel) polymers form this electrolyte. These batteries provide higher specific energy than other lithium battery types and are used in applications where weight is a critical feature, such as mobile devices, radio-controlled aircraft and some electric vehicles.

An electric vehicle (EV) is a vehicle that uses one or more electric motors for propulsion. It can be powered by a collector system, with electricity from extravehicular sources, or it can be powered autonomously by a battery. EVs include, but are not limited to, road and rail vehicles, surface and underwater vessels, electric aircraft, and electric spacecraft. For road vehicles, together with other emerging automotive technologies such as autonomous driving, connected vehicles, and shared mobility, EVs form a future mobility vision called Connected, Autonomous, Shared, and Electric (CASE) Mobility.

The Restriction of Hazardous Substances Directive 2002/95/EC, short for Directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment, was adopted in February 2003 by the European Union.

Green building refers to both a structure and the application of processes that are environmentally responsible and resource-efficient throughout a building's life-cycle: from planning to design, construction, operation, maintenance, renovation, and demolition. This requires close cooperation of the contractor, the architects, the engineers, and the client at all project stages. The Green Building practice expands and complements the classical building design concerns of economy, utility, durability, and comfort. Green building also refers to saving resources to the maximum extent, including energy saving, land saving, water saving, material saving, etc., during the whole life cycle of the building, protecting the environment and reducing pollution, providing people with healthy, comfortable and efficient use of space, and being in harmony with nature Buildings that live in harmony. Green building technology focuses on low consumption, high efficiency, economy, environmental protection, integration and optimization.’

Lithium metal batteries are primary batteries that have metallic lithium as an anode. These types of batteries are also referred to as lithium-metal batteries after lithium-ion batteries had been invented. Most lithium metal batteries are non-rechargeable. However, rechargeable lithium metal batteries are also under development. Since 2007, Dangerous Goods Regulations differentiate between lithium metal batteries and lithium-ion batteries.

Electronic waste or e-waste describes discarded electrical or electronic devices. It is also commonly known as waste electrical and electronic equipment (WEEE) or end-of-life (EOL) electronics. Used electronics which are destined for refurbishment, reuse, resale, salvage recycling through material recovery, or disposal are also considered e-waste. Informal processing of e-waste in developing countries can lead to adverse human health effects and environmental pollution. The growing consumption of electronic goods due to the digital revolution and innovations in science and technology, such as bitcoin, has led to a global e-waste problem and hazard. The rapid exponential increase of e-waste is due to frequent new model releases and unnecessary purchases of electrical and electronic equipment (EEE), short innovation cycles and low recycling rates, and a drop in the average life span of computers.

Battery recycling is a recycling activity that aims to reduce the number of batteries being disposed as municipal solid waste. Batteries contain a number of heavy metals and toxic chemicals and disposing of them by the same process as regular household waste has raised concerns over soil contamination and water pollution.

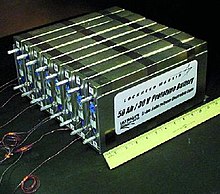

An electric vehicle battery is a rechargeable battery used to power the electric motors of a battery electric vehicle (BEV) or hybrid electric vehicle (HEV).

This is a glossary of environmental science.

Sustainability measurement are a set of frameworks or indicators to measure how sustainable something is. This includes processes, products, services and businesses. Sustainability is difficult to quantify. It may even be impossible to measure. To measure sustainability, the indicators consider environmental, social and economic domains. The metrics are still evolving. They include indicators, benchmarks and audits. They include sustainability standards and certification systems like Fairtrade and Organic. They also involve indices and accounting. And they can include assessment, appraisal and other reporting systems. These metrics are used over a wide range of spatial and temporal scales. Sustainability measures include corporate sustainability reporting, Triple Bottom Line accounting. They include estimates of the quality of sustainability governance for individual countries. These use the Environmental Sustainability Index and Environmental Performance Index. Some methods let us track sustainable development. These include the UN Human Development Index and ecological footprints.

The analysis of the global environment of a company is called global environmental analysis. This analysis is part of a company's analysis-system, which also comprises various other analyses, like the industry analysis, the market analysis and the analyses of companies, clients and competitors. This system can be divided into a macro and micro level. Except for the global environmental analysis, all other analyses can be found on the micro level. Though, the global environmental analysis describes the macro environment of a company. A company is influenced by its environment. Many environmental factors, especially economical or social factors, play a big role in a company's decisions, because the analysis and the monitoring of those factors reveal chances and risks for the company's business. This environmental framework also gives information about location issues. A company is thereby able to determine its location sites. Furthermore, many other strategic decisions are based on this analysis. One may also apply the BBW model. In addition, the factors are analyzed to evaluate external business developments. It is finally the task of the management to adapt the firm to its environment or to influence the environment in an adequate way. The latter is mostly the more difficult option. There are different instruments to analyze the company's environment which are going to be explained afterwards.

The rare earths trade dispute, between China on one side and several countries on the other, was over China's export restrictions on rare earth elements as well as tungsten and molybdenum. Rare earth metals are used to make lithium ion (li-on) batteries, top of the line neodymium magnets, defense products and many electronics.

Since 2011 the European Commission has assessed every 3 years a list of Critical Raw Materials (CRMs) for the EU economy within its Raw Materials Initiative. To date, 14 CRMs were identified in 2011, 20 in 2014, 27 in 2017 and 30 in 2020. These materials are mainly used in energy transition and digital technologies. Then in March 2023 Commission President Ursula von der Leyen proposed the Critical Raw Materials Act, "for a regulation of the European Parliament and of the European Council establishing a framework for ensuring a secure and sustainable supply of critical raw materials". At the time, Europe depended on China for 98% of its rare-earth needs, 97% of its lithium supply and 93% of its magnesium supply.

Electric cars have a smaller environmental footprint than conventional internal combustion engine vehicles (ICEVs). While aspects of their production can induce similar, less or alternative environmental impacts, they produce little or no tailpipe emissions, and reduce dependence on petroleum, greenhouse gas emissions, and health effects from air pollution. Electric motors are significantly more efficient than internal combustion engines and thus, even accounting for typical power plant efficiencies and distribution losses, less energy is required to operate an EV. Manufacturing batteries for electric cars requires additional resources and energy, so they may have a larger environmental footprint from the production phase. EVs also generate different impacts in their operation and maintenance. EVs are typically heavier and could produce more tire and road dust air pollution, but their regenerative braking could reduce such particulate pollution from brakes. EVs are mechanically simpler, which reduces the use and disposal of engine oil.

Lithium batteries are primary batteries that use lithium as an anode. This type of battery is also referred to as a lithium-ion battery and is most commonly used for electric vehicles and electronics. The first type of lithium battery was created by the British chemist M. Stanley Whittingham in the early 1970s and used titanium and lithium as the electrodes. Unfortunately, applications for this battery were limited by the high prices of titanium and the unpleasant scent that the reaction produced. Today's lithium ion battery, modeled after the Whittingham attempt by Akira Yoshino, was first developed in 1985.

The electric vehicle supply chain comprises the mining and refining of raw materials and the manufacturing processes that produce lithium ion batteries and other components for electric vehicles. The lithium-ion battery supply chain is a major component of the overall EV supply chain, and the battery accounts for 30%-40% of the value of the vehicle. Lithium, cobalt, graphite, nickel, and manganese are all critical minerals that are necessary for electric vehicle batteries. There is rapidly growing demand for these materials because of growth in the electric vehicle market, which is driven largely by the proposed transition to renewable energy. Securing the supply chain for these materials is a major world economic issue. Recycling and advancement in battery technology are proposed strategies to reduce demand for raw materials. Supply chain issues could create bottlenecks, increase costs of EVs and slow their uptake.