This article needs additional citations for verification .(December 2006) |

Nikasil is a trademarked electrodeposited lipophilic nickel matrix silicon carbide coating for engine components, mainly piston engine cylinder liners.

This article needs additional citations for verification .(December 2006) |

Nikasil is a trademarked electrodeposited lipophilic nickel matrix silicon carbide coating for engine components, mainly piston engine cylinder liners.

Nikasil was introduced by Mahle in 1967 and was initially developed to allow Wankel engine apex seals to work directly against the aluminum block. [1] This coating allowed aluminum cylinders and pistons to work directly against each other with low wear and friction. Unlike other methods, including cast iron cylinder liners, Nikasil allowed very large cylinder bores with tight tolerances. This made it possible for existing engine designs to be expanded easily. The aluminum cylinders also gave a much better heat conductivity and lower friction than cast iron liners, an important attribute for a high-output engine. The coating was further developed as a replacement for hard-chrome plated cylinder bores for Mercury Marine Racing, and Kohler Engines, and as a repair replacement for factory-chromed snowmobiles, dirt bikes, ATVs, watercraft, and automotive V8 liners/bores.

Nikasil is short for nickel silicon carbide. Silicon carbide is a very hard ceramic (much harder than steel) that can be dissolved in nickel. The nickel silicon carbide solution can then be electroplated onto the aluminium cylinder bore. After the cylinders are plated, the Nikasil bores are diamond-honed to a plateau finish. Pistons will need to be fitted with Nikasil compatible piston rings as chrome rings commonly used with cast iron bores are not compatible. Due to Nikasil's hardness, the resulting cylinder bores are usually long-lived with less cylinder wear than other types of cylinders. As Nikasil is extremely durable, cylinders do not need to be reworked as often as you would an iron or chrome cylinder, usually only requiring deglazing before re-ringing. However, if there is damage to the plating, the cylinder must be stripped before it can be bored and re-plated. [2]

Porsche started using Nikasil on the 1970 917 race car, and later on the 1973 911 RS. Porsche also used it on production cars, but for a short time switched to Alusil due to cost savings for their base 911. Nikasil cylinders were always used for the 911 Turbo and RS models. Nikasil coated aluminium cylinders allowed Porsche to build air-cooled engines that had the highest specific output of any engine of their time.

Nikasil was very popular in the 1990s. It was used by companies such as BMW, Ducati, Jaguar and Moto Guzzi in their new engine families. However, the sulfur found in much of the world's low-quality gasoline caused some Nikasil cylinders to break down over time, causing costly engine failures. [3] Porsche engines did suffer from many issues caused by high sulfur content fuels.[ citation needed ]

Nikasil or similar coatings under other trademarks are also still widely used in racing engines, including those used in Formula One and ChampCar. Suzuki uses a nickel phosphorus-silicon-carbide proprietary coating trademarked SCEM (Suzuki Composite Electro-chemical Material) to maximize cylinder size and improve heat dissipation in the TU250X, Hayabusa, Honda NX250 Enduro and other motorcycles. [4]

Radio-control glow-plug nitro engines commonly use a Nikasil coated sleeved cylinder and an aluminium alloy piston without any compression rings.

In materials science, a metal matrix composite (MMC) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel. The secondary phase is typically a ceramic or another metal. They are typically classified according to the type of reinforcement: short discontinuous fibers (whiskers), continuous fibers, or particulates. There is some overlap between MMCs and cermets, with the latter typically consisting of less than 20% metal by volume. When at least three materials are present, it is called a hybrid composite. MMCs can have much higher strength-to-weight ratios, stiffness, and ductility than traditional materials, so they are often used in demanding applications. MMCs typically have lower thermal and electrical conductivity and poor resistance to radiation, limiting their use in the very harshest environments.

Aluminium–silicon alloys or Silumin is a general name for a group of lightweight, high-strength aluminium alloys based on an aluminum–silicon system (AlSi) that consist predominantly of aluminum - with silicon as the quantitatively most important alloying element. Pure AlSi alloys cannot be hardened, the commonly used alloys AlSiCu and AlSiMg can be hardened. The hardening mechanism corresponds to that of AlCu and AlMgSi.

In a reciprocating engine, the cylinder is the space in which a piston travels.

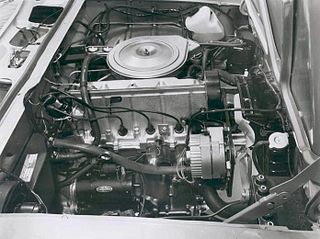

The Chevrolet 2300 is a 2.3-liter straight-four engine produced by the Chevrolet division of General Motors for the 1971 to 1977 model years of the Chevrolet Vega and Chevrolet Monza. This engine was also offered in the 1973–74 Pontiac Astre, the 1975–77 Pontiac Astre, the Pontiac Sunbird for 1976 only, and the Oldsmobile Starfire for 1976–77.

The BMW M52 is a straight-6 DOHC petrol engine which was produced from 1994 to 2000. It was released in the E36 320i, to replace the M50. The BMW S52 engine is a high performance variant of the M52 which powered the American and Canadian market E36 M3 from 1996 to 1999.

BMW M62 is a naturally aspirated V8 petrol engine which was produced from 1995 to 2005. A successor to the BMW M60, the M62 features an aluminium engine block and a single row timing chain.

Plating is a finishing process in which a metal is deposited on a surface. Plating has been done for hundreds of years; it is also critical for modern technology. Plating is used to decorate objects, for corrosion inhibition, to improve solderability, to harden, to improve wearability, to reduce friction, to improve paint adhesion, to alter conductivity, to improve IR reflectivity, for radiation shielding, and for other purposes. Jewelry typically uses plating to give a silver or gold finish.

A hypereutectic piston is an internal combustion engine piston cast using a hypereutectic aluminum alloy with silicon content greater than the eutectic point of 12 weight percent silicon. Most aluminum-silicon casting alloys are hypoeutectic, meaning the silicon content is lower than the eutectic point, and contain relatively fine elemental silicon crystals formed through the eutectic reaction during solidification. In addition to fine silicon crystals, hypereutectic alloys also contain large primary silicon crystals that form before the eutectic reaction. As a result it contains a much higher phase fraction of silicon. Consequently, hypereutectic aluminum has a lower coefficient of thermal expansion, which allows engine designers to specify much tighter tolerances. The silicon content of these alloys is typically 16-19 weight percent, and above this content the mechanical properties and castability degrade substantially. Special molds, casting, and cooling techniques are required to obtain uniformly dispersed primary silicon particles throughout the piston material.

The Suzuki V-Strom 650 is a mid-weight, adventure touring motorcycle made by Suzuki since 2004, in its third generation since model year 2017. It has a standard riding posture, fuel injection and an aluminum chassis. Marketed in Europe, Oceania, the Americas, and since 2018, India, the DL650 is manufactured at Suzuki's final assembly plant in Toyokawa, Japan. The V-Strom 650 trades strength in a single area for adaptability to a variety of riding conditions: commuting, cruising, adventure touring, and to a lesser degree, off-road riding. The bike is variously categorized as dual sport, sport enduro tourer, street/adventure, commuter, or entry-level.

A piston ring is a metallic split ring that is attached to the outer diameter of a piston in an internal combustion engine or steam engine.

Electroless nickel-phosphorus plating, also referred to as E-nickel, is a chemical process that deposits an even layer of nickel-phosphorus alloy on the surface of a solid substrate, like metal or plastic. The process involves dipping the substrate in a water solution containing nickel salt and a phosphorus-containing reducing agent, usually a hypophosphite salt. It is the most common version of electroless nickel plating and is often referred by that name. A similar process uses a borohydride reducing agent, yielding a nickel-boron coating instead.

Alusil as a hypereutectic aluminium-silicon alloy contains approximately 78% aluminium and 17% silicon. This alloy was theoretically conceived in 1927 by Schweizer & Fehrenbach, of Badener Metall-Waren-Fabrik, but practically created only by Lancia in the same year, for its car engines. It was further developed by Reynolds, now Rheinmetall Automotive. In the United States, Chevrolet was the first to use Reynolds A390 in the Chevrolet Vega.

The Suzuki TU250— marketed also as the TU250X, ST250 and ST250 E-Type — is a single-cylinder, air-cooled lightweight street bike manufactured by Suzuki across two generations from 1994 to 2019.

The Honda NX250 is a crossover dual-sport motorcycle produced by Honda, available in the United States from 1988 through 1990. It is a lightweight bike intended for both on-road and off-road riding. The NX250 featured the new MD21E engine which is a liquid-cooled, 249 cc, single-cylinder, four-valve, DOHC, four-stroke with an electric start. It has a bore and stroke of 70.0 mm × 64.8 mm, 11 to 1 compression ratio, and a six-speed transmission. The suspension has 37 mm (1.5 in) forks with 8.7 inches travel up front, and Pro-Link with 7.9" in the rear. The NX250 has a 1,350 mm (53 in) wheelbase and a dry weight of 118 kg (260 lb). The seat height is 820 mm (32 in). In some countries Honda continued production of the NX250 up to 1993, where it was named Honda NX250 Dominator.

The GT series is a series of two-stroke chain drive motorcycles manufactured and marketed by Suzuki for model years 1972–1977, with a range of engine capacities and cylinder counts. Certain markets received the GT380 until model year 1980.

Plasma transferred wire arc (PTWA)thermal spraying is a thermal spraying process that deposits a coating on the internal surface of a cylindrical surface, or external surface of any geometry. It is predominantly known for its use in coating the cylinder bores of an internal combustion engine, enabling the construction of aluminium engine blocks without cast iron cylinder sleeves.

The Suzuki Choinori was a scooter built by Suzuki from 2003 to 2007. It was designed to minimize the use of materials in general and plastics and threaded fasteners in particular in order to minimize cost. The Society of Automotive Engineers of Japan(in Japanese) named the Choinori as one of the 240 Landmarks of Japanese Automotive Technology.

Nigusil is a patented metal alloy created by Moto Guzzi for motorcycle cylinder liners. The name is an acronym for Nickel-Guzzi-Silicon.

The BMW M60 is a naturally aspirated V8 petrol engine which was produced from 1992 to 1996. It was BMW's first V8 engine in over 25 years.

The Volkswagen-Audi V8 engine family is a series of mechanically similar, gasoline-powered and diesel-powered, V-8, internal combustion piston engines, developed and produced by the Volkswagen Group, in partnership with Audi, since 1988. They have been used in various Volkswagen Group models, and by numerous Volkswagen-owned companies. The first spark-ignition gasoline V-8 engine configuration was used in the 1988 Audi V8 model; and the first compression-ignition diesel V8 engine configuration was used in the 1999 Audi A8 3.3 TDI Quattro. The V8 gasoline and diesel engines have been used in most Audi, Volkswagen, Porsche, Bentley, and Lamborghini models ever since. The larger-displacement diesel V8 engine configuration has also been used in various Scania commercial vehicles; such as in trucks, buses, and marine (boat) applications.