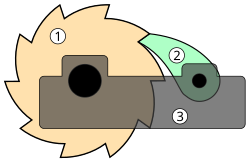

A ratchet (occasionally spelled rachet) is a mechanical device that allows continuous linear or rotary motion in only one direction while preventing motion in the opposite direction. Ratchets are widely used in machinery and tools. [1] The word ratchet is also used informally to refer to a ratcheting socket wrench.