A tire or tyre is a ring-shaped component that surrounds a wheel's rim to transfer a vehicle's load from the axle through the wheel to the ground and to provide traction on the surface traveled over. Most tires, such as those for automobiles and bicycles, are pneumatically inflated structures, which also provide a flexible cushion that absorbs shock as the tire rolls over rough features on the surface. Tires provide a footprint that is designed to match the weight of the vehicle with the bearing strength of the surface that it rolls over by providing a bearing pressure that will not deform the surface excessively.

The circle of forces, traction circle, friction circle, or friction ellipse is a useful way to think about the dynamic interaction between a vehicle's tire and the road surface. The diagram below shows the tire from above, so that the road surface lies in the x-y plane. The vehicle to which the tire is attached is moving in the positive y direction.

Understeer and oversteer are vehicle dynamics terms used to describe the sensitivity of a vehicle to steering. Oversteer is what occurs when a car turns (steers) by more than the amount commanded by the driver. Conversely, understeer is what occurs when a car steers less than the amount commanded by the driver.

The lowsider or lowside is a type of motorcycle or bicycle crash usually occurring in a turn. It is caused when either the front or rear wheel slides out as a result of either too much braking into the corner, too much acceleration through or out of the corner, or too much speed carried into or through the corner for the available grip. It may also be caused by unexpected slippery or loose material on the road surface.

Weight transfer and load transfer are two expressions used somewhat confusingly to describe two distinct effects: the change in load borne by different wheels of even perfectly rigid vehicles during acceleration, and the change in center of mass (CoM) location relative to the wheels because of suspension compliance or cargo shifting or sloshing. In the automobile industry, weight transfer customarily refers to the change in load borne by different wheels during acceleration. This is more properly referred to as load transfer, and that is the expression used in the motorcycle industry, while weight transfer on motorcycles, to a lesser extent on automobiles, and cargo movement on either is due to a change in the CoM location relative to the wheels. This article uses this latter pair of definitions.

Rolling resistance, sometimes called rolling friction or rolling drag, is the force resisting the motion when a body rolls on a surface. It is mainly caused by non-elastic effects; that is, not all the energy needed for deformation of the wheel, roadbed, etc. is recovered when the pressure is removed. Two forms of this are hysteresis losses, and permanent (plastic) deformation of the object or the surface. Another cause of rolling resistance lies in the slippage between the wheel and the surface, which dissipates energy. Note that only the last of these effects involves friction, therefore the name "rolling friction" is to an extent a misnomer.

Steering ratio refers to the ratio between the turn of the steering wheel or handlebars and the turn of the wheels.

A Bundorf analysis is a measure of the characteristics of a vehicle that govern its understeer balance. The understeer is measured in units of degrees of additional yaw per g of lateral acceleration.

Tire Uniformity refers to the dynamic mechanical properties of pneumatic tires as strictly defined by a set of measurement standards and test conditions accepted by global tire and car makers. These standards include the parameters of radial force variation, lateral force variation, conicity, plysteer, radial run-out, lateral run-out, and sidewall bulge. Tire makers worldwide employ tire uniformity measurement as a way to identify poorly performing tires so they are not sold to the marketplace. Both tire and vehicle manufacturers seek to improve tire uniformity in order to improve vehicle ride comfort.

Hans Bastiaan Pacejka was an expert in vehicle system dynamics and particularly in tire dynamics, fields in which his works are now standard references. He was Professor emeritus at Delft University of Technology in Delft, Netherlands.

In (automotive) vehicle dynamics, slip is the relative motion between a tire and the road surface it is moving on. This slip can be generated either by the tire's rotational speed being greater or less than the free-rolling speed, or by the tire's plane of rotation being at an angle to its direction of motion.

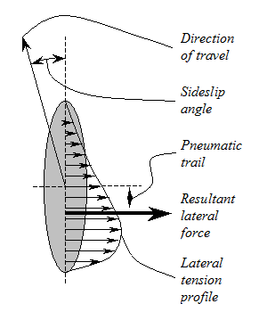

Self aligning torque, also known as aligning torque, aligning moment, SAT, or Mz, is the torque that a tire creates as it rolls along, which tends to steer it, i.e. rotate it around its vertical axis. In the presence of a non-zero slip angle, this torque tends to steer the tire toward the direction in which it is traveling, hence its name.

Motorcycle tyres are the outer part of motorcycle wheels, attached to the rims, providing traction, resisting wear, absorbing surface irregularities, and allowing the motorcycle to turn via countersteering. The two tyres' contact patches are the motorcycle's connection to the ground, and so are fundamental to the motorcycle's suspension behaviour, and critically affect safety, braking, fuel economy, noise, and rider comfort.

The following outline is provided as an overview of and topical guide to tires: