A tire or tyre is a ring-shaped component that surrounds a wheel's rim to transfer a vehicle's load from the axle through the wheel to the ground and to provide traction on the surface over which the wheel travels. Most tires, such as those for automobiles and bicycles, are pneumatically inflated structures, which also provide a flexible cushion that absorbs shock as the tire rolls over rough features on the surface. Tires provide a footprint, called a contact patch, that is designed to match the weight of the vehicle with the bearing strength of the surface that it rolls over by providing a bearing pressure that will not deform the surface excessively.

The circle of forces, traction circle, friction circle, or friction ellipse is a useful way to think about the dynamic interaction between a vehicle's tire and the road surface. The diagram below shows the tire from above, so that the road surface lies in the xy-plane. The vehicle to which the tire is attached is moving in the positive y direction.

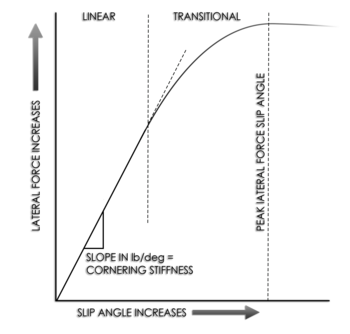

In vehicle dynamics, slip angle or sideslip angle is the angle between the direction in which a wheel is pointing and the direction in which it is actually traveling. This slip angle results in a force, the cornering force, which is in the plane of the contact patch and perpendicular to the intersection of the contact patch and the midplane of the wheel. This cornering force increases approximately linearly for the first few degrees of slip angle, then increases non-linearly to a maximum before beginning to decrease.

Automobile handling and vehicle handling are descriptions of the way a wheeled vehicle responds and reacts to the inputs of a driver, as well as how it moves along a track or road. It is commonly judged by how a vehicle performs particularly during cornering, acceleration, and braking as well as on the vehicle's directional stability when moving in steady state condition.

Rolling is a type of motion that combines rotation and translation of that object with respect to a surface, such that, if ideal conditions exist, the two are in contact with each other without sliding.

Rolling resistance, sometimes called rolling friction or rolling drag, is the force resisting the motion when a body rolls on a surface. It is mainly caused by non-elastic effects; that is, not all the energy needed for deformation of the wheel, roadbed, etc., is recovered when the pressure is removed. Two forms of this are hysteresis losses, and permanent (plastic) deformation of the object or the surface. Note that the slippage between the wheel and the surface also results in energy dissipation. Although some researchers have included this term in rolling resistance, some suggest that this dissipation term should be treated separately from rolling resistance because it is due to the applied torque to the wheel and the resultant slip between the wheel and ground, which is called slip loss or slip resistance. In addition, only the so-called slip resistance involves friction, therefore the name "rolling friction" is to an extent a misnomer.

Torque steer is the unintended influence of engine torque on the steering, especially in front-wheel-drive vehicles. For example, during heavy acceleration, the steering may pull to one side, which may be disturbing to the driver. The effect is manifested either as a tugging sensation in the steering wheel, or a veering of the vehicle from the intended path. Torque steer is directly related to differences in the forces in the contact patches of the left and right drive wheels. The effect becomes more evident when high torques are applied to the drive wheels because of a high overall reduction ratio between the engine and wheels, high engine torque, or some combination of the two. Torque steer is distinct from steering kickback.

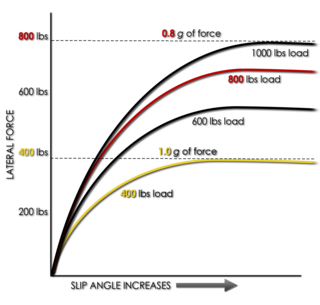

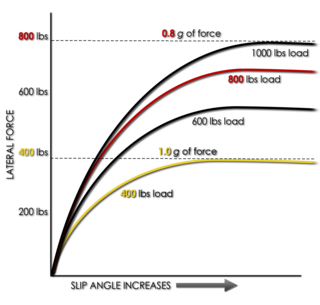

Tire load sensitivity describes the behaviour of tires under load. Conventional pneumatic tires do not behave as classical friction theory would suggest. The load sensitivity of most real tires in their typical operating range is such that the coefficient of friction decreases as the vertical load, Fz, increases. The maximum lateral force that can be developed does increase as the vertical load increases, but at a diminishing rate.

Bicycle and motorcycle dynamics is the science of the motion of bicycles and motorcycles and their components, due to the forces acting on them. Dynamics falls under a branch of physics known as classical mechanics. Bike motions of interest include balancing, steering, braking, accelerating, suspension activation, and vibration. The study of these motions began in the late 19th century and continues today.

A Bundorf analysis is a measure of the characteristics of a vehicle that govern its understeer balance. The understeer is measured in units of degrees of additional yaw per g of lateral acceleration.

Tire uniformity refers to the dynamic mechanical properties of pneumatic tires as strictly defined by a set of measurement standards and test conditions accepted by global tire and car makers.

Hans Bastiaan Pacejka was an expert in vehicle system dynamics and particularly in tire dynamics, fields in which his works are now standard references. He was Professor emeritus at Delft University of Technology in Delft, Netherlands.

In (automotive) vehicle dynamics, slip is the relative motion between a tire and the road surface it is moving on. This slip can be generated either by the tire's rotational speed being greater or less than the free-rolling speed, or by the tire's plane of rotation being at an angle to its direction of motion.

A bicycle tire is a tire that fits on the wheel of a bicycle or similar vehicle. These tires may also be used on tricycles, wheelchairs, and handcycles, frequently for racing. Bicycle tires provide an important source of suspension, generate the lateral forces necessary for balancing and turning, and generate the longitudinal forces necessary for propulsion and braking. Although the use of a pneumatic tire greatly reduces rolling resistance compared to the use of a rigid wheel or solid tire, the tires are still typically, the second largest source, after wind resistance, of power consumption on a level road. The modern detachable pneumatic bicycle tire contributed to the popularity and eventual dominance of the safety bicycle.

Self aligning torque (SAT), also known as aligning torque or aligning moment, is the torque that a tire creates as it rolls along, which tends to steer it, i.e. rotate it around its vertical axis. In the presence of a non-zero slip angle, this torque tends to steer the tire toward the direction in which it is traveling, hence its name.

Pneumatic trail or trail of the tire is a trail-like effect generated by compliant tires rolling on a hard surface and subject to side loads, as in a turn. More technically, it is the distance that the resultant force of side-slip occurs behind the geometric center of the contact patch.

A motorcycle tyre is the outer part of motorcycle wheel, attached to the rim, providing traction, resisting wear, absorbing surface irregularities, and allowing the motorcycle to turn via countersteering. The two tyres' contact patches are the motorcycle's connection to the ground, and so are fundamental to the motorcycle's suspension behaviour, and critically affect safety, braking, fuel economy, noise, and rider comfort.

Camber thrust and camber force are terms used to describe the force generated perpendicular to the direction of travel of a rolling tire due to its camber angle and finite contact patch. Camber thrust is generated when a point on the outer surface of a leaned and rotating tire, that would normally follow a path that is elliptical when projected onto the ground, is forced to follow a straight path while coming in contact with the ground, due to friction. This deviation towards the direction of the lean causes a deformation in the tire tread and carcass that is transmitted to the vehicle as a force in the direction of the lean.

Groove wander, similar to tramlining, is a lateral force acting on a vehicle's wheel resulting from the combination of rain grooves and contoured deformations in the road surface upon which the wheel runs.

The following outline is provided as an overview of and topical guide to tires: