A tire is a ring-shaped component that surrounds a wheel's rim to transfer a vehicle's load from the axle through the wheel to the ground and to provide traction on the surface over which the wheel travels. Most tires, such as those for automobiles and bicycles, are pneumatically inflated structures, providing a flexible cushion that absorbs shock as the tire rolls over rough features on the surface. Tires provide a footprint, called a contact patch, designed to match the vehicle's weight and the bearing on the surface that it rolls over by exerting a pressure that will avoid deforming the surface.

A mountain bike (MTB) or mountain bicycle is a bicycle designed for off-road cycling. Mountain bikes share some similarities with other bicycles, but incorporate features designed to enhance durability and performance in rough terrain, which often makes them heavier, more complex and less efficient on smooth surfaces. These typically include a suspension fork, large knobby tires, more durable wheels, more powerful brakes, straight, wide handlebars to improve balance and comfort over rough terrain, and wide-ratio gearing optimized for topography, application and a frame with a suspension mechanism for the rear wheel. Rear suspension is ubiquitous in heavier-duty bikes and now common even in lighter bikes. Dropper seat posts can be installed to allow the rider to quickly adjust the seat height.

A tire iron is a specialized metal or plastic tool used in working with tires. Tire irons have not been in common use for automobile tires since the shift to the use of tubeless tires in the late 1950s.

A bicycle wheel is a wheel, most commonly a wire wheel, designed for a bicycle. A pair is often called a wheelset, especially in the context of ready built "off the shelf" performance-oriented wheels.

A bicycle pump is a type of positive-displacement air pump specifically designed for inflating bicycle tires. It has a connection or adapter for use with one or both of the two most common types of valves used on bicycles, Schrader or Presta. A third type of valve called the Dunlop valve exists, but tubes with these valves can be filled using a Presta pump.

The Schrader valve is a type of pneumatic tire valve used on virtually every motor vehicle in the world today. The Schrader company, for which it was named, was founded in 1844 by August Schrader. The original Schrader valve design was invented in 1891, and patented in the United States in 1893.

August Schrader (1807–1894) was a German-American inventor and mechanic. He is known for inventing the Schrader valve.

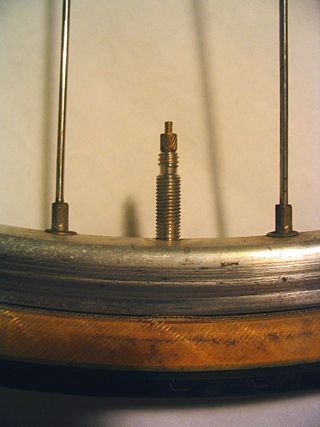

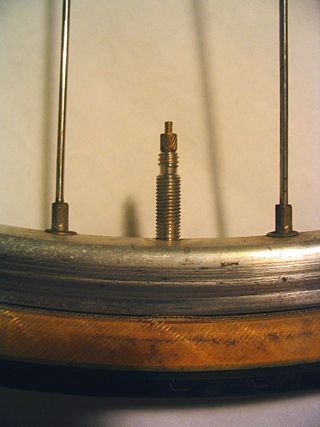

The Presta valve is a type of tire valve commonly found on high pressure bicycle inner tubes and is commonly used on tubeless setups. It consists of an outer valve stem and an inner valve body. A lock nut to secure the stem at the wheel rim and a valve cap may also be present.

ISO 5775 is an international standard for labeling the size of bicycle tires and rims. The system used was originally developed by the European Tyre and Rim Technical Organisation (ETRTO). It is designed to make tire sizing consistent and clear. It replaces overlapping informal systems that ambiguously distinguished between sizes. For example, at least 6 different "26 inch" sizes exist, and "27 inch" wheels have a larger diameter than American "28 inch" wheels. The Japanese Industrial Standards Committee also cooperates with ISO 5775. The corresponding Japanese standards are JIS D 9112 for tires and JIS D 9421 for rims.

Tire bead is the term for the edge of a tire that sits on the rim. Wheels for automobiles, bicycles, etc. are made with a small slot or groove into which the tire bead sits. When the tire is properly inflated, the air pressure within the tire keeps the bead in this groove.

BFGoodrich is an American tire brand. Originally part of the industrial conglomerate Goodrich Corporation, it was acquired in 1990 by the French tire maker Michelin. BFGoodrich was the first American tire manufacturer to make radial tires. It made tires for the then new Winton car from Winton Motor Carriage Company.

The rim is the "outer edge of a wheel, holding the tire". It makes up the outer circular design of the wheel on which the inside edge of the tire is mounted on vehicles such as automobiles. For example, on a bicycle wheel the rim is a large hoop attached to the outer ends of the spokes of the wheel that holds the tire and tube. In cross-section, the rim is deep in the center and shallow at the outer edges, thus forming a "U" shape that supports the bead of the tire casing.

A run-flat tire is a pneumatic vehicle tire designed to resist the effects of deflation when punctured, allowing the vehicle to continue to be driven at reduced speeds for limited distances. First developed by tire manufacturer Michelin in the 1930s, run-flat tires were introduced to the public market in the 1980s. They have increased in popularity over time.

A tire-pressure monitoring system (TPMS) monitors the air pressure inside the pneumatic tires on vehicles. A TPMS reports real-time tire-pressure information to the driver, using either a gauge, a pictogram display, or a simple low-pressure warning light. TPMS can be divided into two different types – direct (dTPMS) and indirect (iTPMS).

A flat tire is a deflated pneumatic tire, which can cause the rim of the wheel to ride on the tire tread or the ground potentially resulting in loss of control of the vehicle or irreparable damage to the tire. The most common cause of a flat tire is the puncturing of the tire by a sharp object, such as a nail or pin, letting the air escape. Depending on the size of the blowout, the tire may deflate slowly or rapidly.

The Dunlop valve, is a type of pneumatic valve stem in use—mostly on inner tubes of bicycles—in many countries, including Japan, Korea, India, Pakistan, Sri Lanka, most European countries, and a number of developing countries. The Dunlop valve has a wider base than a Presta valve, similar enough in size to a Schrader valve to use identically drilled valve holes in rims, but it can be inflated with a Presta valve adapter. The inner mechanism of the valve can be replaced easily, without the need for special tools.

A bicycle tire is a tire that fits on the wheel of a bicycle or similar vehicle. These tires may also be used on tricycles, wheelchairs, and handcycles, frequently for racing. Bicycle tires provide an important source of suspension, generate the lateral forces necessary for balancing and turning, and generate the longitudinal forces necessary for propulsion and braking. Although the use of a pneumatic tire greatly reduces rolling resistance compared to the use of a rigid wheel or solid tire, the tires are still typically the second largest source, after wind resistance, of power consumption on a level road. The modern detachable pneumatic bicycle tire contributed to the popularity and eventual dominance of the safety bicycle.

A tubular tyre, referred to as a tub in Britain, a sew-up in the US, a single in Australia, or just a tubular is a bicycle tyre that is stitched closed around the inner tube to form a torus. The combination is then glued onto a specially designed rim, referred to as a "sprint rim" in Britain, and just a "tubular rim" in the US, of a bicycle wheel.

The following outline is provided as an overview of and topical guide to tires:

An inner tube is an inflatable torus that forms the interior of some pneumatic tires. The tube is inflated through a valve stem and fits inside the tire casing. The inflated inner tube provides structural support and suspension, while the outer tire offers grip and protects the more fragile tube.