A tire or tyre is a ring-shaped component that surrounds a wheel's rim to transfer a vehicle's load from the axle through the wheel to the ground and to provide traction on the surface over which the wheel travels. Most tires, such as those for automobiles and bicycles, are pneumatically inflated structures, which also provide a flexible cushion that absorbs shock as the tire rolls over rough features on the surface. Tires provide a footprint, called a contact patch, that is designed to match the weight of the vehicle with the bearing strength of the surface that it rolls over by providing a bearing pressure that will not deform the surface excessively.

A tire iron is a specialized metal tool used in working with tires. Tire irons have not been in common use for automobile tires since the shift to the use of tubeless tires in the late 1950s.

A bicycle brake reduces the speed of a bicycle or prevents it from moving. The three main types are: rim brakes, disc brakes, and drum brakes.

A bicycle wheel is a wheel, most commonly a wire wheel, designed for a bicycle. A pair is often called a wheelset, especially in the context of ready built "off the shelf" performance-oriented wheels.

The wheel size for a motor vehicle or similar wheel has a number of parameters.

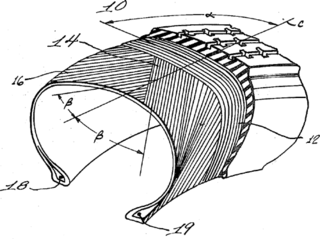

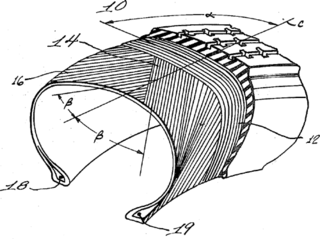

A radial tire is a particular design of vehicular tire. In this design, the cord plies are arranged at 90 degrees to the direction of travel, or radially. Radial tire construction climbed to 100% market share in North America following Consumer Reports finding the superiority of the radial design in 1968, and were standard by 1976.

The term bicycle tools usually refers to specialty tools only used on bicycles, as opposed to general purpose mechanical tools such as spanners and hex wrenches. Various bicycle tools' have evolved over the years into specialized tools for working on a bicycle. Modern bicycle shops will stock a large number of tools for working on different bicycle parts. This work can be performed by a trained bicycle mechanic, or for simple tasks, by the bicycle owner.

Tire bead is the term for the edge of a tire that sits on the rim. Wheels for automobiles, bicycles, etc. are made with a small slot or groove into which the tire bead sits. When the tire is properly inflated, the air pressure within the tire keeps the bead in this groove.

A beadlock or bead lock is a mechanical device that secures the bead of a tire to the wheel of a vehicle. Tires and wheels are designed so that when the tire is inflated, the tire pressure pushes the bead of the tire against the inside of the wheel rim so that the tire stays on the wheel and the two rotate together. In situations where tire pressure is insufficient to hold the bead of the tire in place, a beadlock is needed.

The rim is the "outer edge of a wheel, holding the tire". It makes up the outer circular design of the wheel on which the inside edge of the tire is mounted on vehicles such as automobiles. For example, on a bicycle wheel the rim is a large hoop attached to the outer ends of the spokes of the wheel that holds the tire and tube. In cross-section, the rim is deep in the center and shallow at the outer edges, thus forming a "U" shape that supports the bead of the tire casing.

Radial force variation or road force variation (RFV) is a property of a tire that affects steering, traction, braking and load support. High values of RFV for a given tire reflect a high level of manufacturing variations in the tire structure that will impart ride disturbances into the vehicle in the vertical direction. RFV is measured according to processes specified by the ASTM International in ASTM F1806 – Standard Practice for Tire Testing.

Automotive tires are described by an alphanumeric tire code or tyre code, which is generally molded into the sidewall of the tire. This code specifies the dimensions of the tire, and some of its key limitations, such as load-bearing ability, and maximum speed. Sometimes the inner sidewall contains information not included on the outer sidewall, and vice versa.

Pneumatic tires are manufactured according to relatively standardized processes and machinery, in around 455 tire factories in the world. With over 1 billion tires manufactured worldwide annually, the tire industry is a major consumer of natural rubber. Tire factories start with bulk raw materials such as synthetic rubber, carbon black, and chemicals and produce numerous specialized components that are assembled and cured.

Plus sizing is the practice of replacing an automotive wheel with one of a larger diameter fitted with a new tire of lower aspect ratio so that the new tire has close to the same diameter and circumference as the original tire to minimize any changes in speedometer accuracy, torque and traction control, while reducing sidewall flex and (generally) increasing cornering ability.

A flat tire is a deflated pneumatic tire, which can cause the rim of the wheel to ride on the tire tread or the ground potentially resulting in loss of control of the vehicle or irreparable damage to the tire. The most common cause of a flat tire is puncturing of the tire by a sharp object, such as a nail or pin, letting the air escape. Depending on the size of the puncture, the tire may deflate slowly or rapidly.

Tire uniformity refers to the dynamic mechanical properties of pneumatic tires as strictly defined by a set of measurement standards and test conditions accepted by global tire and car makers.

The Michelin TRX, (and the related TDX), is a radial tire introduced by the Michelin Group in 1975. It is one of the first volume-produced low-profile tires. Although technologically advanced, and reasonably successful, the tire's requirement for a non-standard rim ultimately condemned it to a relatively short commercial life. It has thus been called the "Betamax of the tire industry."

A bicycle tire is a tire that fits on the wheel of a bicycle or similar vehicle. These tires may also be used on tricycles, wheelchairs, and handcycles, frequently for racing. Bicycle tires provide an important source of suspension, generate the lateral forces necessary for balancing and turning, and generate the longitudinal forces necessary for propulsion and braking. Although the use of a pneumatic tire greatly reduces rolling resistance compared to the use of a rigid wheel or solid tire, the tires are still typically, the second largest source, after wind resistance, of power consumption on a level road. The modern detachable pneumatic bicycle tire contributed to the popularity and eventual dominance of the safety bicycle.

A tire changer is a machine used to help tire technicians dismount and mount tires with automobile wheels. After the wheel and tire assembly are removed from the automobile, the tire changer has all the components necessary to remove and replace the tire from the wheel. Different tire changers allow technicians to replace tires on automobiles, motorcycles and heavy-duty trucks. New tire and wheel technology has improved certain tire changers to be able to change a low profile tire or a run-flat tire.