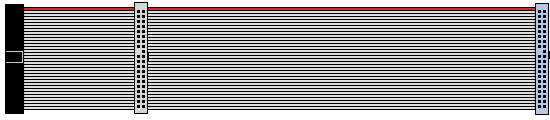

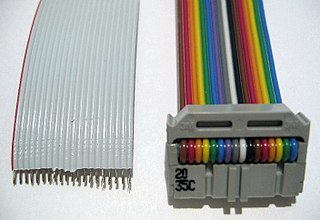

Parallel ATA (PATA), originally AT Attachment, also known as Integrated Drive Electronics (IDE), is a standard interface designed for IBM PC-compatible computers. It was first developed by Western Digital and Compaq in 1986 for compatible hard drives and CD or DVD drives. The connection is used for storage devices such as hard disk drives, floppy disk drives, optical disc drives, and tape drives in computers.

In microelectronics, a dual in-line package is an electronic component package with a rectangular housing and two parallel rows of electrical connecting pins. The package may be through-hole mounted to a printed circuit board (PCB) or inserted in a socket. The dual-inline format was invented by Don Forbes, Rex Rice and Bryant Rogers at Fairchild R&D in 1964, when the restricted number of leads available on circular transistor-style packages became a limitation in the use of integrated circuits. Increasingly complex circuits required more signal and power supply leads ; eventually microprocessors and similar complex devices required more leads than could be put on a DIP package, leading to development of higher-density chip carriers. Furthermore, square and rectangular packages made it easier to route printed-circuit traces beneath the packages.

A breadboard, solderless breadboard, or protoboard is a construction base used to build semi-permanent prototypes of electronic circuits. Unlike a perfboard or stripboard, breadboards do not require soldering or destruction of tracks and are hence reusable. For this reason, breadboards are also popular with students and in technological education.

Components of an electrical circuit are electrically connected if an electric current can run between them through an electrical conductor. An electrical connector is an electromechanical device used to create an electrical connection between parts of an electrical circuit, or between different electrical circuits, thereby joining them into a larger circuit.

Zero insertion force (ZIF) is a type of IC socket or electrical connector that requires very little force for insertion. With a ZIF socket, before the IC is inserted, a lever or slider on the side of the socket is moved, pushing all the sprung contacts apart so that the IC can be inserted with very little force - generally the weight of the IC itself is sufficient and no external downward force is required. The lever is then moved back, allowing the contacts to close and grip the pins of the IC. ZIF sockets are much more expensive than standard IC sockets and also tend to take up a larger board area due to the space taken up by the lever mechanism. Typically, they are only used when there is a good reason to do so.

In electronics and particularly computing, a jumper is a short length of conductor used to close, open or bypass part of an electronic circuit. They are typically used to set up or configure printed circuit boards, such as the motherboards of computers. The process of setting a jumper is often called strapping.

A ball grid array (BGA) is a type of surface-mount packaging used for integrated circuits. BGA packages are used to permanently mount devices such as microprocessors. A BGA can provide more interconnection pins than can be put on a dual in-line or flat package. The whole bottom surface of the device can be used, instead of just the perimeter. The traces connecting the package's leads to the wires or balls which connect the die to package are also on average shorter than with a perimeter-only type, leading to better performance at high speeds.

An edge connector is the portion of a printed circuit board (PCB) consisting of traces leading to the edge of the board that are intended to plug into a matching socket. The edge connector is a money-saving device because it only requires a single discrete female connector, and they also tend to be fairly robust and durable. They are commonly used in computers for expansion slots for peripheral cards, such as PCI, PCI Express, and AGP cards.

Stripboard is the generic name for a widely used type of electronics prototyping material for circuit boards characterized by a pre-formed 0.1 inches (2.54 mm) regular (rectangular) grid of holes, with wide parallel strips of copper cladding running in one direction all the way along one side of an insulating bonded paper board. It is commonly also known by the name of the original product Veroboard, which is a trademark, in the UK, of British company Vero Technologies Ltd and Canadian company Pixel Print Ltd. It was originated and developed in the early 1960s by the Electronics Department of Vero Precision Engineering Ltd (VPE). It was introduced as a general-purpose material for use in constructing electronic circuits - differing from purpose-designed printed circuit boards (PCBs) in that a variety of electronics circuits may be constructed using a standard wiring board.

The D-subminiature or D-sub is a common type of electrical connector. They are named for their characteristic D-shaped metal shield. When they were introduced, D-subs were among the smallest connectors used on computer systems.

A banana connector is a single-wire electrical connector used for joining wires to equipment. The term 4 mm connector is also used, especially in Europe, although not all banana connectors will mate with 4 mm parts, and 2 mm banana connectors exist. Various styles of banana plug contacts exist, all based on the concept of spring metal applying outward force into the unsprung cylindrical jack to produce a snug fit with good electrical conductivity. Common types include: a solid pin split lengthwise and splayed slightly, a tip of four leaf springs, a cylinder with a single leaf spring on one side, a bundle of stiff wire, a central pin surrounded by a multiple-slit cylinder with a central bulge, or simple sheet spring metal rolled into a nearly complete cylinder. The plugs are frequently used to terminate patch cords for electronic test equipment such as laboratory power supply units, while sheathed banana plugs are common on multimeter probe leads.

Berg connector is a brand of electrical connector used in computer hardware. Berg connectors are manufactured by Berg Electronics Corporation of St. Louis, Missouri, now part of Amphenol.

The micro ribbon or miniature ribbonconnector is a common type of electrical connector for a variety of applications, such as in computer and telecommunications equipment having many contacts.

An insulation-displacement contact (IDC), also known as insulation-piercing contact (IPC), is an electrical connector designed to be connected to the conductor(s) of an insulated cable by a connection process which forces a selectively sharpened blade or blades through the insulation, bypassing the need to strip the conductors of insulation before connecting. When properly made, the connector blade cold-welds to the conductor, making a theoretically reliable gas-tight connection.

A SCSI connector is used to connect computer parts that communicate with each other via the SCSI standard. Generally, two connectors, designated male and female, plug together to form a connection which allows two components, such as a computer and a disk drive, to communicate with each other. SCSI connectors can be electrical connectors or optical connectors. There have been a large variety of SCSI connectors in use at one time or another in the computer industry. Twenty-five years of evolution and three major revisions of the standards resulted in requirements for Parallel SCSI connectors that could handle an 8, 16 or 32 bit wide bus running at 5, 10 or 20 megatransfer/s, with conventional or differential signaling. Serial SCSI added another three transport types, each with one or more connector types. Manufacturers have frequently chosen connectors based on factors of size, cost, or convenience at the expense of compatibility.

A modular connector is a type of electrical connector for cords and cables of electronic devices and appliances, such as in computer networking, telecommunication equipment, and audio headsets.

A pin header is a form of electrical connector. A male pin header consists of one or more rows of metal pins molded into a plastic base, often 2.54 mm (0.1 in) apart, though available in many spacings. Male pin headers are cost-effective due to their simplicity. The female counterparts are sometimes known as female headers, though there are numerous naming variations of male and female connectors. Historically, headers have sometimes been called "Berg connectors" or "DuPont" connectors, but headers are manufactured by many companies.

JST connectors are electrical connectors manufactured to the design standards originally developed by J.S.T. Mfg. Co.. JST manufactures numerous series (families) and pitches of connectors.

In electronics, prototyping means building an actual circuit to a theoretical design to verify that it works, and to provide a physical platform for debugging it if it does not. The prototype is often constructed using techniques such as wire wrapping or using a breadboard, stripboard or perfboard, with the result being a circuit that is electrically identical to the design but not physically identical to the final product.