| Sisu KB-124 and KB-121 | |

|---|---|

| |

| Overview | |

| Manufacturer | Oy Suomen Autoteollisuus Ab |

| Also called | Nalle-Sisu |

| Production | |

| Assembly | Karis, Finland |

| Body and chassis | |

| Layout | 4×2 |

| Powertrain | |

| Engine | Sisu petrol and Ford diesel engines 52.2–62.7 kW (70.0–84.1 hp) → table |

| Transmission | 4+1 manual; 2nd, 3rd and 4th gears with synchromesh [4] [5] |

| Dimensions | |

| Wheelbase | 2,500–4,000 mm (98.4–157.5 in) → table |

| Chronology | |

| Predecessor | Sisu KB-24 |

Sisu KB-124 was a two-axle lorry and special vehicle chassis made by the Finnish heavy vehicle manufacturer Suomen Autoteollisuus (SAT). It was a six-tonne delivery lorry which was developed to follow the KB-24. The KB-124 was produced from 1961 until 1968, when it was replaced by the similar KB-121 with increased permitted load. Production ceased in about 1972.

Contents

- Development

- Production

- Technical data

- Engine

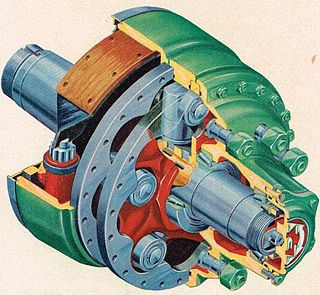

- Chassis and transmission

- Cabin and superstructures

- Dimensions and weights

- Characteristics

- Sources

- References

The marketing name for the vehicle was Nalle-Sisu, "Teddy-Bear-Sisu". In addition to lorries, the chassis was bodied as fire engines, mobile shops and small buses by coachbuilders.