Bread is a staple food prepared from a dough of flour and water, usually by baking. Throughout recorded history and around the world, it has been an important part of many cultures' diet. It is one of the oldest human-made foods, having been of significance since the dawn of agriculture, and plays an essential role in both religious rituals and secular culture.

A croissant is a buttery, flaky, viennoiserie pastry inspired by the shape of the Austrian kipferl but using the French yeast-leavened laminated dough. Croissants are named for their historical crescent shape. The dough is layered with butter, rolled and folded several times in succession, then rolled into a thin sheet, in a technique called laminating. The process results in a layered, flaky texture, similar to a puff pastry.

A Danish pastry is a multilayered, laminated sweet pastry in the viennoiserie tradition. The concept was brought to Denmark by Austrian bakers, where the recipe was partly changed and accommodated by the Danes to their liking, and has since developed into a Danish specialty. Like other viennoiserie pastries, such as croissants, it is a variant of puff pastry made of laminated yeast-leavened dough that creates a layered texture.

Sourdough or sourdough bread is a bread made by the fermentation of dough using wild lactobacillaceae and yeast. Lactic acid from fermentation imparts a sour taste and improves keeping qualities.

Baker's yeast is the common name for the strains of yeast commonly used in baking bread and other bakery products, serving as a leavening agent which causes the bread to rise by converting the fermentable sugars present in the dough into carbon dioxide and ethanol. Baker's yeast is of the species Saccharomyces cerevisiae, and is the same species as the kind commonly used in alcoholic fermentation, which is called brewer's yeast or the deactivated form nutritional yeast. Baker's yeast is also a single-cell microorganism found on and around the human body.

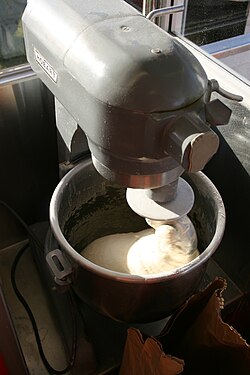

Dough is a thick, malleable, sometimes elastic paste made from grains or from leguminous or chestnut crops. Dough is typically made by mixing flour with a small amount of water or other liquid and sometimes includes yeast or other leavening agents, as well as ingredients such as fats or flavorings.

A bread making machine or breadmaker is a home appliance for baking bread. It consists of a bread pan, at the bottom of which are one or more built-in paddles, mounted in the center of a small special-purpose oven. The machine is usually controlled by a built-in computer using settings input via a control panel. Most bread machines have different cycles for different kinds of dough—including white bread, whole grain, European-style, and dough-only. Many also have a timer to allow the bread machine to function without operator input, and some high-end models allow the user to program a custom cycle.

Quick bread is any bread leavened with a chemical leavening agent rather than a biological one like yeast or sourdough starter. An advantage of quick breads is their ability to be prepared quickly and reliably, without requiring the time-consuming skilled labor and the climate control needed for traditional yeast breads.

Biga is a type of pre-fermentation used in Italian baking. Many popular Italian breads, including ciabatta, are made using a biga. Using a biga adds complexity to the bread's flavor and is often used in breads that need a light, open texture with holes. Apart from adding to flavor and texture, a biga also helps to preserve bread by making it less perishable.

In biology, autolysis, more commonly known as self-digestion, refers to the destruction of a cell through the action of its own enzymes. It may also refer to the digestion of an enzyme by another molecule of the same enzyme.

In cooking, kneading is a process in the making of bread or dough, used to mix the ingredients and add strength to the final product. Its importance lies in the mixing of flour with water; when these two ingredients are combined and kneaded, the gliadin and glutenin proteins in the flour expand and form strands of gluten, which gives bread its texture. The kneading process warms and stretches these gluten strands, eventually creating a springy and elastic dough. If bread dough is not kneaded enough, it will not be able to hold the tiny pockets of gas created by the leavening agent, and will collapse, leaving a heavy and dense loaf.

Baker's percentage is a notation method indicating the proportion of an ingredient relative to the flour used in a recipe when making breads, cakes, muffins, and other baked goods. It is also referred to as baker's math, and may be indicated by a phrase such as based on flour weight. It is sometimes called formula percentage, a phrase that refers to the sum of a set of baker's percentages. Baker's percentage expresses a ratio in percentages of each ingredient's weight to the total flour weight:

A ferment is a fermentation starter used in indirect methods of bread making. It may also be called mother dough.

The Chorleywood bread process (CBP) is a method of efficient dough production to make yeasted bread quickly, producing a soft, fluffy loaf. Compared to traditional bread-making processes, CBP uses more yeast, added fats, chemicals, and high-speed mixing to allow the dough to be made with lower-protein wheat, and produces bread in a shorter time. It was developed by Bill Collins, George Elton and Norman Chamberlain of the British Baking Industries Research Association at Chorleywood in 1961. As of 2009, 80% of bread made in the United Kingdom used the process.

In cooking, proofing is a step in the preparation of yeast bread and other baked goods in which the dough is allowed to rest and rise a final time before baking. During this rest period, yeast ferments the dough and produces gases, thereby leavening the dough.

Vienna bread is a type of bread that is produced from a process developed in Vienna, Austria, in the 19th century. The Vienna process used high milling of Hungarian grain, and cereal press-yeast for leavening.

Salt-rising bread is a dense white bread that is traditional in the Appalachian Mountains, leavened by naturally occurring wild bacteria rather than by yeast. Salt-rising bread is made from wheat flour; a starter consisting of either water or milk and corn, potatoes or wheat; and minor ingredients such as salt and sugar.[1] Some common ways of eating salt-rising bread include a slice with sugared coffee poured over it, a grilled cheese sandwich, and the most popular preference, buttered toast.[1]

The sponge and dough method is a two-step bread making process: in the first step a sponge is made and allowed to ferment for a period of time, and in the second step the sponge is added to the final dough's ingredients, creating the total formula. In this usage, synonyms for sponge are yeast starter or yeast pre-ferment. In French baking the sponge and dough method is known as levain-levure. The method is reminiscent of the sourdough or levain methods; however, the sponge is made from all fresh ingredients prior to being used in the final dough.

In the United States and Canada, a biscuit is a variety of baked bread with a firm, dry exterior and a soft, crumbly interior. It is made with baking powder as a leavening agent rather than yeast, and at times is called a baking powder biscuit to differentiate it from other types. Like other forms of bread, a biscuit is often served with butter or other condiments, flavored with other ingredients, or combined with other types of food to make sandwiches or other dishes.