A wall is a structure and a surface that defines an area; carries a load; provides security, shelter, or soundproofing; or, is decorative. There are many kinds of walls, including:

Siding or wall cladding is the protective material attached to the exterior side of a wall of a house or other building. Along with the roof, it forms the first line of defense against the elements, most importantly sun, rain/snow, heat and cold, thus creating a stable, more comfortable environment on the interior side. The siding material and style also can enhance or detract from the building's beauty. There is a wide and expanding variety of materials to side with, both natural and artificial, each with its own benefits and drawbacks. Masonry walls as such do not require siding, but any wall can be sided. Walls that are internally framed, whether with wood, or steel I-beams, however, must always be sided.

A curtain wall is an exterior covering of a building in which the outer walls are non-structural, instead serving to protect the interior of the building from the elements. Because the curtain wall façade carries no structural load beyond its own dead load weight, it can be made of lightweight materials. The wall transfers lateral wind loads upon it to the main building structure through connections at floors or columns of the building.

A load-bearing wall or bearing wall is a wall that is an active structural element of a building, which holds the weight of the elements above it, by conducting its weight to a foundation structure below it.

Prefabrication is the practice of assembling components of a structure in a factory or other manufacturing site, and transporting complete assemblies or sub-assemblies to the construction site where the structure is to be located. Some researchers refer it to “various materials joined together to form a component of the final installation procedure“. The most commonly cited definition is by Goodier and Gibb in 2007, which described the process of manufacturing and preassembly of a certain number of building components, modules, and elements before their shipment and installation on construction sites.

A concrete block, also known as a cinder block in North American English, breeze block in British English, concrete masonry unit (CMU), or by various other terms, is a standard-size rectangular block used in building construction. The use of blockwork allows structures to be built in the traditional masonry style with layers of staggered blocks.

This page is a list of construction topics.

Sound Transmission Class is an integer rating of how well a building partition attenuates airborne sound. In the US, it is widely used to rate interior partitions, ceilings, floors, doors, windows and exterior wall configurations. Outside the US, the ISO Sound Reduction Index (SRI) is used. The STC rating very roughly reflects the decibel reduction of noise that a partition can provide. The STC is useful for evaluating annoyance due to speech sounds, but not music or machinery noise as these sources contain more low frequency energy than speech.

Framing, in construction, is the fitting together of pieces to give a structure support and shape. Framing materials are usually wood, engineered wood, or structural steel. The alternative to framed construction is generally called mass wall construction, where horizontal layers of stacked materials such as log building, masonry, rammed earth, adobe, etc. are used without framing.

Steel frame is a building technique with a "skeleton frame" of vertical steel columns and horizontal I-beams, constructed in a rectangular grid to support the floors, roof and walls of a building which are all attached to the frame. The development of this technique made the construction of the skyscraper possible.

Formwork is molds into which concrete or similar materials are either precast or cast-in-place. In the context of concrete construction, the falsework supports the shuttering molds. In specialty applications formwork may be permanently incorporated into the final structure, adding insulation or helping reinforce the finished structure.

A countertop, also counter top, counter, benchtop, worktop or kitchen bench, bunker is a raised, firm, flat, and horizontal surface. They are built for work in kitchens or other food preparation areas, bathrooms or lavatories, and workrooms in general. The surface is frequently installed upon and supported by cabinets, positioned at an ergonomic height for the user and the particular task for which it is designed. A countertop may be constructed of various materials with different attributes of functionality, durability and aesthetics, and may have built-in appliances, or accessory items relative to the intended application.

Precast concrete is a construction product produced by casting concrete in a reusable mold or "form" which is then cured in a controlled environment, transported to the construction site and maneuvered into place; examples include precast beams, and wall panels for tilt up construction. In contrast, cast-in-place concrete is poured into site-specific forms and cured on site.

Stone veneer is a thin layer of any stone used as decorative facing material that is not meant to be load bearing. Stone cladding is a stone veneer, or simulated stone, applied to a building or other structure made of a material other than stone. Stone cladding is sometimes applied to concrete and steel buildings as part of their original architectural design.

Glass fibre reinforced concrete (GFRC) is a type of fibre-reinforced concrete. The product is also known as glassfibre reinforced concrete or GRC in British English. Glass fibre concretes are mainly used in exterior building façade panels and as architectural precast concrete. Somewhat similar materials are fibre cement siding and cement boards.

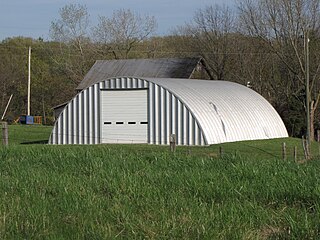

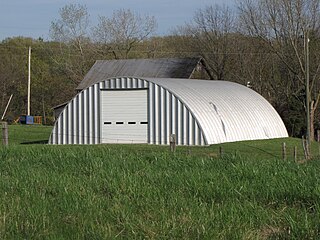

A steel building is a metal structure fabricated with steel for the internal support and for exterior cladding, as opposed to steel framed buildings which generally use other materials for floors, walls, and external envelope. Steel buildings are used for a variety of purposes including storage, work spaces and living accommodation. They are classified into specific types depending on how they are used.

The Filigree Wideslab method is a process for construction of concrete floor decks from two interconnected concrete placements, one precast in a factory, and the other done in the field. The method was developed during the late 1960s by Harry H. Wise as a more efficient and economic construction process than conventional cast-in-place technologies.

Prefabs were a major part of the delivery plan to address the United Kingdom's post–Second World War housing shortage. They were envisaged by war-time prime minister Winston Churchill in March 1944, and legally outlined in the Housing Act 1944.

The Hastings Prototype House is located at Farragut Parkway and High Street in Hastings-on-Hudson, New York, United States. It is a Moderne-style concrete building erected during the 1930s. In 1991 it was added to the National Register of Historic Places.

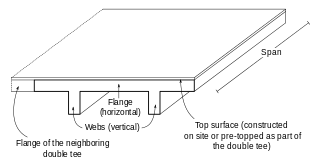

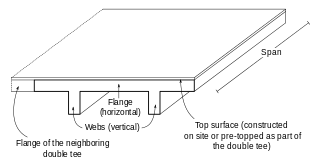

A double tee or double-T beam is a load-bearing structure that resembles two T-beams connected to each other side by side. The strong bond of the flange and the two webs creates a structure that is capable of withstanding high loads while having a long span. The typical sizes of double tees are up to 15 feet (4.6 m) for flange width, up to 5 feet (1.5 m) for web depth, and up to 80 feet (24 m) or more for span length. Double tees are pre-manufactured from prestressed concrete which allows construction time to be shortened.