Type casting is a technique for casting the individual letters known as sorts used in hot metal typesetting by pouring molten metal into brass moulds called matrices.

Type casting is a technique for casting the individual letters known as sorts used in hot metal typesetting by pouring molten metal into brass moulds called matrices.

Woodblock printing had been known in China for centuries. It was innovations in type casting that made for Gutenberg's breakthrough of commercially printing. [1] Although using matrices was a technique known well before his time, Johannes Gutenberg adapted their use to a conveniently adjustable hand mould, enabling one to easily and accurately cast identical multiple instances of any character.

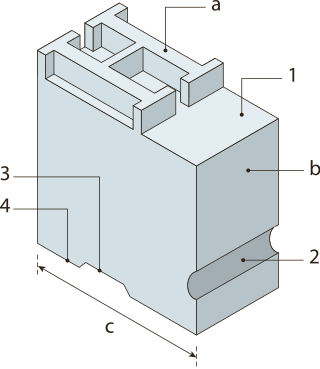

The ultimate product of manual typecasting were letters, known as sorts for letterpress printing, and the process starts with the installation of a matrix with the impression of a particular glyph into the bottom of the hand mould which is adjusted for the width of the body and locked in preparation for casting. Molten type metal alloy would be carefully poured into a straight-sided vertical cavity at the top of the mould. The type caster would then give the mould a quick shake to aid the flow of type metal into every cavity of the matrix. In practice it was discovered that different glyphs would require different shakes to cast the characters properly. As the casting cooled down and solidified, the mould would be unlocked and the sort removed, ready for later finishing operations and locked again ready for the next character.

Manual casting was a long drawn-out process, but was able to produce precise and consistent excellent results. [1]

In 1805 Henri Didot of Paris, France patented a type casting machine. [2]

David Bruce invented the first automated type casting machine in 1838, but it was the Monotype and Linotype machines that first effectively speeded up the process. [3]

In 1887, Tolbert Lanston invented the Monotype mechanical typesetting machine. This was a type casting system that produced individual characters, in which a matrix case is used for holding all the font's matrices. In a manner somewhat reminiscent to hand type casting, every time a character is to be cast, the selection mechanism would position the matrix case so that the correct matrix is over the mould, hot metal would be injected, the sort removed and the process repeated until the job is finished.

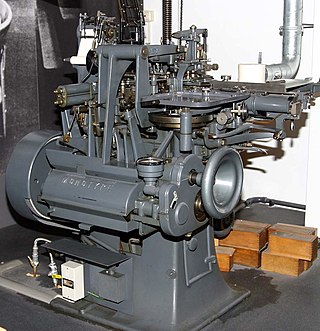

Although the Linotype (1886) and Intertype (1914) approach to mechanical typesetting produced cast slugs that usually represent the complete line instead of individual characters, it still made use of individual bronze matrices stored in a magazine at the top of the machine, dispensed one per keystroke, assembled, sent to the caster where the slug was cast and the matrices re-distributed using a clever V-shaped keying mechanism.

The Ludlow display typecasting system is similar, in that it is also a linecasting process, although all the typesetting operations (matrix assembly and later distribution) are executed manually by a compositor.

Subsequent typesetting technologies made use of glyphs represented as photographic negatives or digital descriptions.

Movable type is the system and technology of printing and typography that uses movable components to reproduce the elements of a document usually on the medium of paper.

The Mergenthaler Linotype Company is a corporation founded in the United States in 1886 to market the Linotype machine, a system to cast metal type in lines (linecaster) invented by Ottmar Mergenthaler. It became the world's leading manufacturer of book and newspaper typesetting equipment; outside North America, its only serious challenger for book typesetting was the Anglo-American Monotype Corporation.

In printing, type metal refers to the metal alloys used in traditional typefounding and hot metal typesetting. Historically, type metal was an alloy of lead, tin and antimony in different proportions depending on the application, be it individual character mechanical casting for hand setting, mechanical line casting or individual character mechanical typesetting and stereo plate casting. The proportions used are in the range: lead 50‒86%, antimony 11‒30% and tin 3‒20%. Antimony and tin are added to lead for durability while reducing the difference between the coefficients of expansion of the matrix and the alloy. Apart from durability, the general requirements for type-metal are that it should produce a true and sharp cast, and retain correct dimensions and form after cooling down. It should also be easy to cast, at reasonable low melting temperature, iron should not dissolve in the molten metal, and mould and nozzles should stay clean and easy to maintain. Today, Monotype machines can utilize a wide range of different alloys. Mechanical linecasting equipment uses alloys that are close to eutectic.

Typesetting is the composition of text by means of arranging physical type in mechanical systems or glyphs in digital systems representing characters. Stored types are retrieved and ordered according to a language's orthography for visual display. Typesetting requires one or more fonts. One significant effect of typesetting was that authorship of works could be spotted more easily, making it difficult for copiers who have not gained permission.

The Linotype machine is a "line casting" machine used in printing which is manufactured and sold by the former Mergenthaler Linotype Company and related companies. It was a hot metal typesetting system that cast lines of metal type for individual uses. Linotype became one of the mainstay methods to set type, especially small-size body text, for newspapers, magazines, and posters from the late 19th century to the 1970s and 1980s, when it was largely replaced by phototypesetting and digital typesetting. The name of the machine comes from the fact that it produces an entire line of metal type at once, hence a line-o'-type. It was a significant improvement over the previous industry standard of manual, letter-by-letter typesetting using a composing stick and shallow subdivided trays, called "cases".

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

Phototypesetting is a method of setting type which uses photography to make columns of type on a scroll of photographic paper. It has been made obsolete by the popularity of the personal computer and desktop publishing.

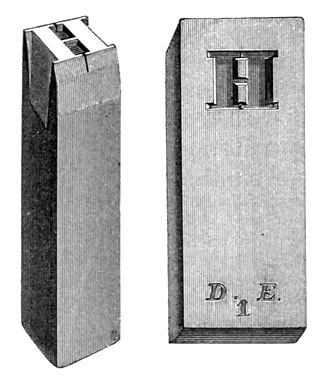

In the manufacture of metal type used in letterpress printing, a matrix is the mould used to cast a letter, known as a sort. Matrices for printing types were made of copper.

Monotype Imaging Holdings Inc., founded as Lanston Monotype Machine Company in 1887 in Philadelphia by Tolbert Lanston, is an American company that specializes in digital typesetting and typeface design for use with consumer electronics devices. Incorporated in Delaware and headquartered in Woburn, Massachusetts, the company has been responsible for many developments in printing technology—in particular the Monotype machine, which was a fully mechanical hotmetal typesetter, that produced texts automatically, all single type. Monotype was involved in the design and production of many typefaces in the 20th century. Monotype developed many of the most widely used typeface designs, including Times New Roman, Gill Sans, Arial, Bembo and Albertus.

In printing and typography, hot metal typesetting is a technology for typesetting text in letterpress printing. This method injects molten type metal into a mold that has the shape of one or more glyphs. The resulting sorts or slugs are later used to press ink onto paper. Normally the typecasting machine would be controlled by a keyboard or by a paper tape.

Punchcutting is a craft used in traditional typography to cut letter punches in steel as the first stage of making metal type. Steel punches in the shape of the letter would be used to stamp matrices into copper, which were locked into a mould shape to cast type. Cutting punches and casting type was the first step of traditional typesetting. The cutting of letter punches was a highly skilled craft requiring much patience and practice. Often the designer of the type would not be personally involved in the cutting.

Janson is the name given to a set of old-style serif typefaces from the Dutch Baroque period, and modern revivals from the twentieth century. Janson is a crisp, relatively high-contrast serif design, most popular for body text.

In printing, a stereotype, stereoplate or simply a stereo, is a solid plate of type metal, cast from a papier-mâché or plaster mould taken from the surface of a forme of type. The mould was known as a flong.

In typesetting, a sort or type is a block with a typographic character etched on it, used—when lined up with others—to print text. In movable-type printing, the sort or type is cast from a matrix mold and assembled by hand with other sorts bearing additional characters into lines of type to make up a form, from which a page is printed.

A Ludlow Typograph is a hot metal typesetting system used in letterpress printing. The device casts bars, or slugs of type, out of type metal primarily consisting of lead. These slugs are used for the actual printing, and then are melted down and recycled on the spot. It was used to print large-type material such as newspaper headlines or posters.

The Type Archive was a collection of artefacts representing the legacy of type founding in England, whose famous type foundries and composing systems supplied the world with type in over 300 languages. The Archive was founded in 1992 by Susan Shaw in Stockwell, South London. The Archive announced in mid-2022 that it would relinquish its building and return portions of its collections to other institutions.

Sabon is an old-style serif typeface designed by the German-born typographer and designer Jan Tschichold (1902–1974) in the period 1964–1967. It was released jointly by the Linotype, Monotype, and Stempel type foundries in 1967. The design of the roman is based on types by Claude Garamond, particularly a specimen printed by the Frankfurt printer Konrad Berner. Berner had married the widow of a fellow printer Jacques Sabon, the source of the face's name, who had bought some of Garamond's type after his death. The italics are based on types designed by a contemporary of Garamond's, Robert Granjon. It is effectively a Garamond revival, though a different name was chosen as many other modern typefaces already carry this name.

The Intertype Corporation produced the Intertype, a typecasting machine closely resembling the Linotype, and using the same matrices as the Linotype. It was founded in New York in 1911 by Hermann Ridder, of Ridder Publications, as the International Typesetting Machine Company, but purchased by a syndicate for $1,650,000 in 1916 and reorganized as the Intertype Corporation.

The Monotype system is a system for printing by hot-metal typesetting from a keyboard. The two most significant differences from the competing Linotype machine are that

Ehrhardt is an old-style serif typeface released by the British branch of the Monotype Corporation in 1938. Ehrhardt is a modern adaptation of printing types of "stout Dutch character" from the Dutch Baroque tradition sold by the Ehrhardt foundry in Leipzig. These were cut by the Hungarian-Transylvanian pastor and punchcutter Miklós (Nicholas) Tótfalusi Kis while in Amsterdam in the period from 1680 to 1689.