The Boeing 777, commonly referred to as the Triple Seven, is an American long-range wide-body airliner developed and manufactured by Boeing Commercial Airplanes. The 777 is the world's largest twinjet and the most-built wide-body airliner. The jetliner was designed to bridge the gap between Boeing's other wide body airplanes, the twin-engined 767 and quad-engined 747, and to replace aging DC-10 and L-1011 trijets. Developed in consultation with eight major airlines, the 777 program was launched in October 1990, with an order from United Airlines. The prototype aircraft rolled out in April 1994, and first flew in June of that year. The 777 entered service with the launch operator United Airlines in June 1995. Longer-range variants were launched in 2000, and first delivered in 2004.

The fuselage is an aircraft's main body section. It holds crew, passengers, or cargo. In single-engine aircraft, it will usually contain an engine as well, although in some amphibious aircraft the single engine is mounted on a pylon attached to the fuselage, which in turn is used as a floating hull. The fuselage also serves to position the control and stabilization surfaces in specific relationships to lifting surfaces, which is required for aircraft stability and maneuverability.

The Boeing 787 Dreamliner is an American wide-body airliner developed and manufactured by Boeing Commercial Airplanes. After dropping its unconventional Sonic Cruiser project, Boeing announced the conventional 7E7 on January 29, 2003, which focused largely on efficiency. The program was launched on April 26, 2004, with an order for 50 aircraft from All Nippon Airways (ANA), targeting a 2008 introduction. On July 8, 2007, a prototype 787 without major operating systems was rolled out; subsequently the aircraft experienced multiple delays, until its maiden flight on December 15, 2009. Type certification was received in August 2011, and the first 787-8 was delivered in September 2011 before entering commercial service on October 26, 2011, with ANA.

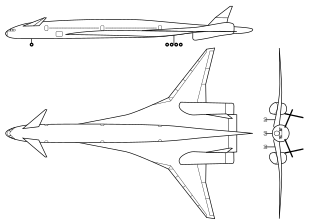

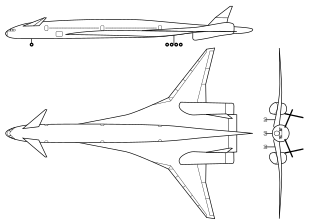

The Boeing Sonic Cruiser was a concept jet airliner with a delta wing–canard configuration. It was distinguished from conventional airliners by its delta wing and high-subsonic cruising speed of up to Mach 0.98. Boeing first proposed it in 2001, but airlines generally preferred lower operating costs over higher speed. Boeing ended the Sonic Cruiser project in December 2002 and shifted to the slower but more fuel-efficient 7E7 airliner.

The mechanical structure of an aircraft is known as the airframe. This structure is typically considered to include the fuselage, undercarriage, empennage and wings, and excludes the propulsion system.

The Museum of Flight is a private non-profit air and space museum in the Seattle metropolitan area. It is located at the southern end of King County International Airport in the city of Tukwila, immediately south of Seattle. It was established in 1965 and is fully accredited by the American Alliance of Museums. As the largest private air and space museum in the world, it also hosts large K–12 educational programs.

The maiden flight, also known as first flight, of an aircraft is the first occasion on which it leaves the ground under its own power. The same term is also used for the first launch of rockets.

Boeing Commercial Airplanes (BCA) is a division of the Boeing Company. It designs, assembles, markets, and sells commercial aircraft, including the 737, 767, 777, and 787, along with freighter and business jet variants of most. The division employs nearly 35,000 people, many working at the company's division headquarters in Renton, Washington or at more than a dozen engineering, manufacturing, and assembly facilities, notably the Everett Factory and Renton Factory, and the South Carolina Factory.

Cabin pressurization is a process in which conditioned air is pumped into the cabin of an aircraft or spacecraft in order to create a safe and comfortable environment for humans flying at high altitudes. For aircraft, this air is usually bled off from the gas turbine engines at the compressor stage, and for spacecraft, it is carried in high-pressure, often cryogenic, tanks. The air is cooled, humidified, and mixed with recirculated air by one or more environmental control systems before it is distributed to the cabin.

The Boeing Yellowstone Project was a Boeing Commercial Airplanes project to replace its entire civil aircraft portfolio with advanced technology aircraft. New technologies to be introduced include composite aerostructures, more electrical systems, and more fuel-efficient turbofan engines. The term "Yellowstone" refers to the technologies, while "Y1" through "Y3" refer to the actual aircraft.

The Boeing Dreamlifter, officially the 747-400 Large Cargo Freighter (LCF), is a wide-body cargo aircraft modified extensively from the Boeing 747-400 airliner. With a volume of 65,000 cubic feet (1,840 m3) it can hold three times that of a 747-400F freighter. The outsized aircraft was designed to transport Boeing 787 Dreamliner parts between Italy, Japan, and the U.S., but has also flown medical supplies during the COVID-19 pandemic.

The aft pressure bulkhead or rear pressure bulkhead is the rear component of the pressure seal in all aircraft that cruise in a tropopause zone in the Earth's atmosphere. It helps maintain pressure when stratocruising and protects the aircraft from bursting due to the higher internal pressure.

Hexcel Corporation is an American public industrial materials company, based in Stamford, Connecticut. The company develops and manufactures structural materials. Hexcel was formed from the combination of California Reinforced Plastics, Ciba Composites and Hercules Composites Products Division. The company sells its products in commercial, military and recreational markets for use in commercial and military aircraft, space launch vehicles and satellites, wind turbine blades, sports equipment and automotive products. Hexcel works with Airbus Group, The Boeing Company, and others. Since 1980, the firm has publicly traded on the New York Stock Exchange under the ticker symbol HXL.

The Boeing Everett Factory, officially the Everett Production Facility, is an airplane assembly facility operated by Boeing in Everett, Washington, United States. It sits on the north side of Paine Field and includes the largest building in the world by volume at over 472 million cubic feet (13,400,000 m3), which covers 98.3 acres (39.8 ha).

Boeing South Carolina is an airplane assembly facility built by Boeing in North Charleston, South Carolina, United States. Located on the grounds of the joint-use Charleston Air Force Base and Charleston International Airport, the site is the final assembly and delivery point for the Boeing 787 Dreamliner. Boeing opened the site in July 2011, after purchasing the facilities of suppliers Vought and Global Aeronautica in 2008 and 2009. The final assembly building covers 1,200,000 square feet (110,000 m2) and opened on November 12, 2011. As of September 28, 2017, the site employs 6,943 workers and contractors.

In 2013, the second year of service for the Boeing 787 Dreamliner, a widebody jet airliner, several of the aircraft suffered from electrical system problems stemming from its lithium-ion batteries. Incidents included two electrical fires, one aboard an All Nippon Airways 787 and another on a Japan Airlines 787; the second fire was found by maintenance workers while the aircraft was parked at Boston's Logan International Airport. The United States Federal Aviation Administration (FAA) ordered a review of the design and manufacture of the Boeing 787 Dreamliner and grounded the entire Boeing 787 fleet, the first such grounding since that of the McDonnell Douglas DC-10 in 1979. The plane has had two major battery thermal runaway events in 52,000 flight hours, neither of which were contained safely; this length of time between failures was substantially less than the 10 million flight hours predicted by Boeing.

The Boeing 777X is the latest series of the long-range, wide-body, twin-engine jetliners in the Boeing 777 family from Boeing Commercial Airplanes. The changes for 777X include GE9X engines, composite wings with folding wingtips, greater cabin width and seating capacity, and technologies from the Boeing 787. The 777X was launched in November 2013 with two variants: the 777-8 and the 777-9. The 777-8 provides seating for 395 passengers and has a range of 8,745 nmi while the 777-9 has seating for 426 passengers and a range of over 7,285 nmi.

John J. Tracy is the retired chief technology officer (CTO) of The Boeing Company, the world's largest aerospace company. At Boeing, he held the dual roles of CTO and Senior Vice President of Engineering, Operations & Technology from June 2006 to mid 2016.

The Automobili Lamborghini Advanced Composite Structures Laboratory (ACSL), commonly referred to as the Lamborghini Lab, was a research and development facility based in Seattle, Washington from 2007 to 2018, which focused on the development of carbon fiber composite technologies for Automobili Lamborghini S.p.A. The ACSL also designed and developed carbon fiber products for other organizations in other industries. The hallmark technology pioneered by the Lamborghini Lab is the forged composite technology.

John Mitchell Barnett was an American whistleblower who was known for his substantiated safety and quality reports to the Federal Aviation Administration (FAA) about Boeing's production of the Boeing 787 Dreamliner and death which occurred amidst a lawsuit he brought against Boeing. Barnett worked in quality control at Boeing for 32 years, serving for seven as a manager at Boeing South Carolina. Barnett was one of several employees to go public about malpractices at Boeing beginning in 2019 with The New York Times and was featured in the 2022 Netflix documentary titled Downfall: The Case Against Boeing.