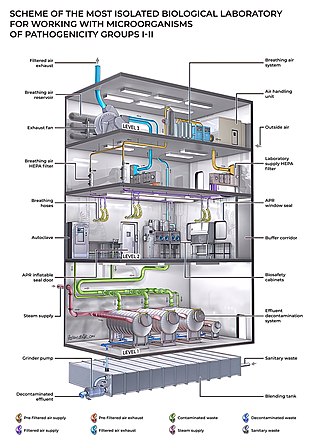

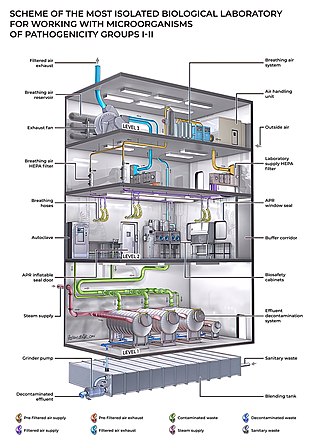

A biosafety level (BSL), or pathogen/protection level, is a set of biocontainment precautions required to isolate dangerous biological agents in an enclosed laboratory facility. The levels of containment range from the lowest biosafety level 1 (BSL-1) to the highest at level 4 (BSL-4). In the United States, the Centers for Disease Control and Prevention (CDC) have specified these levels in a publication referred to as BMBL. In the European Union, the same biosafety levels are defined in a directive. In Canada the four levels are known as Containment Levels. Facilities with these designations are also sometimes given as P1 through P4, as in the term P3 laboratory.

A fume hood is a type of local exhaust ventilation device that is designed to limit exposure to hazardous or toxic fumes, vapors or dusts. The device is an enclosure with a movable sash window on one side that traps and exhausts gases and particulates either out of the area or back into the room, and is most frequently used in laboratory settings.

A cleanroom or clean room is an engineered space, which maintains a very low concentration of airborne particulates. It is well isolated, well-controlled from contamination, and actively cleansed. Such rooms are commonly needed for scientific research, and in industrial production for all nanoscale processes, such as semiconductor manufacturing. A cleanroom is designed to keep everything from dust, to airborne organisms, or vaporised particles, away from it, and so from whatever material is being handled inside it.

Sterilization refers to any process that removes, kills, or deactivates all forms of life and other biological agents present in or on a specific surface, object, or fluid. Sterilization can be achieved through various means, including heat, chemicals, irradiation, high pressure, and filtration. Sterilization is distinct from disinfection, sanitization, and pasteurization, in that those methods reduce rather than eliminate all forms of life and biological agents present. After sterilization, an object is referred to as being sterile or aseptic.

HEPA filter, also known as high-efficiency particulate absorbing filter and high-efficiency particulate arrestance filter, is an efficiency standard of air filters.

A glovebox is a sealed container that is designed to allow one to manipulate objects where a separate atmosphere is desired. Built into the sides of the glovebox are gloves arranged in such a way that the user can place their hands into the gloves and perform tasks inside the box without breaking containment. Part or all of the box is usually transparent to allow the user to see what is being manipulated. Two types of gloveboxes exist. The first allows a person to work with hazardous substances, such as radioactive materials or infectious disease agents, and the second allows manipulation of substances that must be contained within a very high purity inert atmosphere, such as argon or nitrogen. It is also possible to use a glovebox for manipulation of items in a vacuum chamber.

A kitchen hood, exhaust hood, hood fan, extractor hood, or range hood is a device containing a mechanical fan that hangs above the stove or cooktop in the kitchen. It removes airborne grease, combustion products, fumes, smoke, heat, and steam from the air by evacuation of the air and filtration. In commercial kitchens exhaust hoods are often used in combination with fire suppression devices so that fumes from a grease fire are properly vented and the fire is put out quickly. Commercial vent hoods may also be combined with a fresh air fan that draws in exterior air, circulating it with the cooking fumes, which is then drawn out by the hood.

Ultraviolet germicidal irradiation (UVGI) is a disinfection technique employing ultraviolet (UV) light, particularly UV-C (180-280 nm), to kill or inactivate microorganisms. UVGI primarily inactivates microbes by damaging their genetic material, thereby inhibiting their capacity to carry out vital functions.

Barrier isolator is a general term that includes two types of devices: isolators and restricted access barriers (RABS). Both are devices that provide a physical and aerodynamic barrier between the external clean room environment and a work process. The isolator design is the more dependable of the two barrier design choices, as it prevents contamination hazards by achieving a more comprehensive separation of the processing environment from the surrounding facility. Nonetheless, both Isolator and RABS designs are contemporary approaches developed over the last 35 years and a great advancement over designs of the 1950s-70s that were far more prone to microbial contamination problems.

Aerobiological engineering is the science of designing buildings and systems to control airborne pathogens and allergens in indoor environments. The most-common environments include commercial buildings, residences and hospitals. This field of study is important because controlled indoor climates generally tend to favor the survival and transmission of contagious human pathogens as well as certain kinds of fungi and bacteria.

A biosafety cabinet (BSC)—also called a biological safety cabinet or microbiological safety cabinet—is an enclosed, ventilated laboratory workspace for safely working with materials contaminated with pathogens requiring a defined biosafety level. Several different types of BSC exist, differentiated by the degree of biocontainment they provide. BSCs first became commercially available in 1950.

A fan filter unit (FFU) is a type of motorized air filtering equipment. It is used to supply purified air to cleanrooms, laboratories, medical facilities or microenvironments by removing harmful airborne particles from recirculating air. The units are installed within the system's ceiling or floor grid. Large cleanrooms require a proportionally large number of FFUs, which in some cases may range from several hundred to several thousand. Units often contain their own pre-filter, HEPA filter and internally controllable fan air distribution.

Positive pressure personnel suits (PPPS)—or positive pressure protective suits, informally known as "space suits", "moon suits", "blue suits", etc.—are highly specialized, totally encapsulating, industrial protection garments worn only within special biocontainment or maximum containment (BSL-4) laboratory facilities. These facilities research dangerous pathogens which are highly infectious and may have no treatments or vaccines available. These facilities also feature other special equipment and procedures such as airlock entry, quick-drench disinfectant showers, special waste disposal systems, and shower exits.

The Aeromedical Isolation Team of the US Army Medical Research Institute of Infectious Diseases (USAMRIID) at Fort Detrick, Maryland was a military rapid response team with worldwide airlift capability designed to safely evacuate and manage contagious patients under high-level (BSL-4) bio-containment conditions. Created in 1978, during its final years the AIT was one of MEDCOM’s Special Medical Augmentation Response Teams comprising a portable containment laboratory along with its transit isolators for patient transport. Contingency missions included bioterrorism scenarios as well as the extraction of scientists with exotic infections from remote sites in foreign countries. The AIT trained continuously and was often put on alert status, but only deployed for “real world” missions four times. The AIT was decommissioned in 2010 and its mission was assumed by one of the US Air Force’s Critical Care Air Transport Teams (CCATTs).

A Racal suit is a protective suit with a powered air-purifying respirator (PAPR). It consists of a plastic suit and a battery-operated blower with HEPA filters that supplies filtered air to a positive-pressure hood. Racal suits were among the protective suits used by the Aeromedical Isolation Team (AIT) of the United States Army Medical Research Institute of Infectious Diseases to evacuate patients with highly infectious diseases for treatment.

A powered air-purifying respirator (PAPR) is a type of respirator used to safeguard workers against contaminated air. PAPRs consist of a headgear-and-fan assembly that takes ambient air contaminated with one or more type of pollutant or pathogen, actively removes (filters) a sufficient proportion of these hazards, and then delivers the clean air to the user's face or mouth and nose. They have a higher assigned protection factor than filtering facepiece respirators such as N95 masks. PAPRs are sometimes called positive-pressure masks, blower units, or just blowers.

Engineering controls are strategies designed to protect workers from hazardous conditions by placing a barrier between the worker and the hazard or by removing a hazardous substance through air ventilation. Engineering controls involve a physical change to the workplace itself, rather than relying on workers' behavior or requiring workers to wear protective clothing.

The health and safety hazards of nanomaterials include the potential toxicity of various types of nanomaterials, as well as fire and dust explosion hazards. Because nanotechnology is a recent development, the health and safety effects of exposures to nanomaterials, and what levels of exposure may be acceptable, are subjects of ongoing research. Of the possible hazards, inhalation exposure appears to present the most concern, with animal studies showing pulmonary effects such as inflammation, fibrosis, and carcinogenicity for some nanomaterials. Skin contact and ingestion exposure, and dust explosion hazards, are also a concern.

Engineering controls for nanomaterials are a set of hazard control methods and equipment for workers who interact with nanomaterials. Engineering controls are physical changes to the workplace that isolate workers from hazards, and are considered the most important set of methods for controlling the health and safety hazards of nanomaterials after systems and facilities have been designed.

Mechanical filters are a class of filter for air-purifying respirators that mechanically stops particulates from reaching the wearer's nose and mouth. They come in multiple physical forms.