Crochet is a process of creating textiles by using a crochet hook to interlock loops of yarn, thread, or strands of other materials. The name is derived from the French term croc, which means 'hook'. Hooks can be made from a variety of materials, such as metal, wood, bamboo, bone or plastic. The key difference between crochet and knitting, beyond the implements used for their production, is that each stitch in crochet is completed before the next one is begun, while knitting keeps many stitches open at a time. Some variant forms of crochet, such as Tunisian crochet and broomstick lace, do keep multiple crochet stitches open at a time.

Knitting is a method for production of textile fabrics by interlacing yarn loops with loops of the same or other yarns. It is used to create many types of garments. Knitting may be done by hand or by machine.

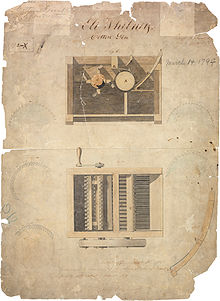

Cotton is a soft, fluffy staple fiber that grows in a boll, or protective case, around the seeds of the cotton plants of the genus Gossypium in the mallow family Malvaceae. The fiber is almost pure cellulose, and can contain minor percentages of waxes, fats, pectins, and water. Under natural conditions, the cotton bolls will increase the dispersal of the seeds.

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, different fabric types, etc. At first, the word "textiles" only referred to woven fabrics. However, weaving is not the only manufacturing method, and many other methods were later developed to form textile structures based on their intended use. Knitting and non-woven are other popular types of fabric manufacturing. In the contemporary world, textiles satisfy the material needs for versatile applications, from simple daily clothing to bulletproof jackets, spacesuits, and doctor's gowns.

Yarn is a long continuous length of interlocked fibres, used in sewing, crocheting, knitting, weaving, embroidery, ropemaking, and the production of textiles. Thread is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or other lubricants to withstand the stresses involved in sewing. Embroidery threads are yarns specifically designed for needlework. Yarn can be made of a number of natural or synthetic materials, and comes in a variety of colors and thicknesses. Although yarn may be dyed different colours, most yarns are solid coloured with a uniform hue.

Textile arts are arts and crafts that use plant, animal, or synthetic fibers to construct practical or decorative objects.

An overlock is a kind of stitch that sews over the edge of one or two pieces of cloth for edging, hemming, or seaming. Usually an overlock sewing machine will cut the edges of the cloth as they are fed through, though some are made without cutters. The inclusion of automated cutters allows overlock machines to create finished seams easily and quickly. An overlock sewing machine differs from a lockstitch sewing machine in that it uses loopers fed by multiple thread cones rather than a bobbin. Loopers serve to create thread loops that pass from the needle thread to the edges of the fabric so that the edges of the fabric are contained within the seam.

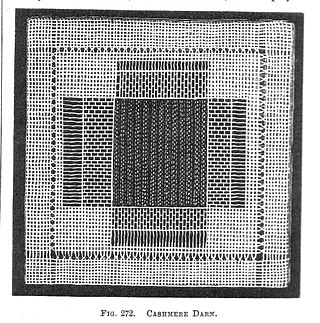

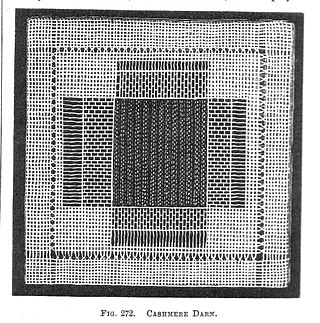

Darning is a sewing technique for repairing holes or worn areas in fabric or knitting using needle and thread alone. It is often done by hand, but using a sewing machine is also possible. Hand darning employs the darning stitch, a simple running stitch in which the thread is "woven" in rows along the grain of the fabric, with the stitcher reversing direction at the end of each row, and then filling in the framework thus created, as if weaving. Darning is a traditional method for repairing fabric damage or holes that do not run along a seam, and where patching is impractical or would create discomfort for the wearer, such as on the heel of a sock.

The textile industry is primarily concerned with the design, production and distribution of textiles: yarn, cloth and clothing. The raw material may be natural, or synthetic using products of the chemical industry.

Textile manufacturing is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products.

A stocking frame was a mechanical knitting machine used in the textiles industry. It was invented by William Lee of Calverton near Nottingham in 1589. Its use, known traditionally as framework knitting, was the first major stage in the mechanisation of the textile industry, and played an important part in the early history of the Industrial Revolution. It was adapted to knit cotton and to do ribbing, and by 1800 had been adapted as a lace making machine.

Warp knitting is defined as a loop-forming process in which the yarn is fed into the knitting zone, parallel to the fabric selvage. It forms vertical loops in one course and then moves diagonally to knit the next course. Thus the yarns zigzag from side to side along the length of the fabric. Each stitch in a course is made by many different yarns. Each stitch in one wale is made by several different yarns.

A selvage or selvedge is a "self-finished" edge of a piece of fabric which keeps it from unraveling and fraying. The term "self-finished" means that the edge does not require additional finishing work, such as hem or bias tape, to prevent fraying.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fiber from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, which turns yarn into cloth. The machine used for weaving is the loom. For decoration, the process of colouring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

The study of the history of clothing and textiles traces the development, use, and availability of clothing and textiles over human history. Clothing and textiles reflect the materials and technologies available in different civilizations at different times. The variety and distribution of clothing and textiles within a society reveal social customs and culture.

In textile manufacturing, finishing refers to the processes that convert the woven or knitted cloth into a usable material and more specifically to any process performed after dyeing the yarn or fabric to improve the look, performance, or "hand" (feel) of the finish textile or clothing. The precise meaning depends on context.

Textile manufacturing is one of the oldest human activities. The oldest known textiles date back to about 5000 B.C. In order to make textiles, the first requirement is a source of fibre from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving to create cloth. The machine used for weaving is the loom. Cloth is finished by what are described as wet process to become fabric. The fabric may be dyed, printed or decorated by embroidering with coloured yarns.

A bolt is a piece of cloth woven on a loom or created by a knitting machine, as it is processed, stored and/or marketed. Consequently, its dimensions are highly variable – flexible and dependent upon the manufacturing, machinery, quantity, size, thickness and quality of the product. It is a unit used in manufacturing, transport and inventory. It is also used as a descriptor for wallpaper, which uses different fabrication machinery. Being encompassing, it is by its nature a generic and ambiguous term of convenience and context, used to describe fabric and wallpaper.

Sewing is the craft of fastening or attaching objects using stitches made with needle and thread. Sewing is one of the oldest of the textile arts, arising in the Paleolithic Era. Although usually associated with clothing and household linens, sewing is used in a variety of crafts and industries, including shoemaking, upholstery, sailmaking, bookbinding and the manufacturing of some kinds of sporting goods. Sewing is the fundamental process underlying a variety of textile arts and crafts, including embroidery, tapestry, quilting, appliqué and patchwork.

Greige goods are loom state woven fabrics, or unprocessed knitted fabrics. Greige goods undergo many subsequent processes, for instance, dyeing, printing, bleaching, and finishing, prior to further converting to finished goods such as clothing, or other textile products. "Grey fabrics" is another term to refer to unfinished woven or knitted fabrics.