A circular saw or a buzz saw, is a power-saw using a toothed or abrasive disc or blade to cut different materials using a rotary motion spinning around an arbor. A hole saw and ring saw also use a rotary motion but are different from a circular saw. Circular saws may also be loosely used for the blade itself. Circular saws were invented in the late 18th century and were in common use in sawmills in the United States by the middle of the 19th century.

A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge used to cut through material. Various terms are used to describe toothed and abrasive saws.

A chainsaw is a saw that cuts with a set of teeth attached to a rotating chain driven along a guide bar. Modern chainsaws are used in activities such as tree felling, limbing, bucking, pruning, cutting firebreaks in wildland fire suppression, harvesting of firewood, for use in chainsaw art and chainsaw mills, for cutting concrete, and cutting ice. Precursors to modern chainsaws were first used in surgery, with patents for wood chainsaws beginning in the late 19th century.

Portable sawmills are sawmills small enough to be moved easily and set up in the field. They have existed for over 100 years but grew in popularity in the United States starting in the 1970s, when the 1973 oil crisis and the back-to-the-land movement had led to renewed interest in small woodlots and in self-sufficiency. Their popularity has grown exponentially since 1982, when the portable bandsaw mill was first commercialized.

A table saw is a woodworking tool, consisting of a circular saw blade, mounted on an arbor, that is driven by an electric motor. The drive mechanism is mounted below a table that provides support for the material, usually wood, being cut, with the blade protruding up through the table into the material.

In woodworking, a rip-cut is a type of cut that severs or divides a piece of wood parallel to the grain. The other typical type of cut is a cross-cut, a cut perpendicular to the grain. Unlike cross-cutting, which shears the wood fibers, a rip saw works more like a series of chisels, lifting off small splinters of wood. The nature of the wood grain requires the shape of the saw teeth to be different, thus the need for both rip saws and crosscut saws; however, some circular saw blades are combination blades and can make both types of cuts. A rip cut is the fundamental type of cut made at a sawmill.

A radial arm saw is a cutting machine consisting of a circular saw mounted on a sliding horizontal arm. Invented by Raymond DeWalt in 1922, the radial arm saw was the primary tool used for cutting long pieces of stock to length until the introduction of the power miter saw in the 1970s.

A saw filer is a person who maintains and repairs saws in a saw mill. A saw filer's work area in the mill is called the filing room.

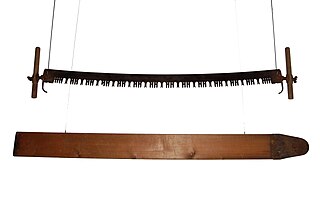

A bandsaw is a power saw with a long, sharp blade consisting of a continuous band of toothed metal stretched between two or more wheels to cut material. They are used principally in woodworking, metalworking, and lumbering, but may cut a variety of materials. Advantages include uniform cutting action as a result of an evenly distributed tooth load, and the ability to cut irregular or curved shapes like a jigsaw. The minimum radius of a curve is determined by the width of the band and its kerf. Most bandsaws have two wheels rotating in the same plane, one of which is powered, although some may have three or four to distribute the load. The blade itself can come in a variety of sizes and tooth pitches, which enables the machine to be highly versatile and able to cut a wide variety of materials including wood, metal and plastic.

A hacksaw is a fine-toothed saw, originally and mainly made for cutting metal. The equivalent saw for cutting wood is usually called a bow saw.

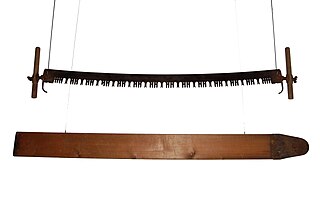

A crosscut saw is any saw designed for cutting wood perpendicular to (across) the wood grain. Crosscut saws may be small or large, with small teeth close together for fine work like woodworking or large for coarse work like log bucking, and can be a hand tool or power tool.

A miter saw or mitre saw is a saw used to make accurate crosscuts and miters in a workpiece by positioning a mounted blade onto a board. A miter saw in its earliest form was composed of a back saw in a miter box, but in modern implementation consists of a powered circular saw that can be positioned at a variety of angles and lowered onto a board positioned against a backstop called the fence.

Chainsaws and chainsaw operations have specific risk control methods.

A scroll saw is a small electric or pedal-operated saw used to cut intricate curves in wood, metal, or other materials. The fineness of its blade allows it to cut more delicately than a power jigsaw, and more easily than a hand coping saw or fretsaw. Like those tools, it is capable of creating curved cuts with angled edges, by tilting its table along the axis of the cut.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

An abrasive saw, also known as a cut-off saw or chop saw, is a circular saw which is typically used to cut hard materials, such as metals, tile, and concrete. The cutting action is performed by an abrasive disc, similar to a thin grinding wheel. Technically speaking this is not a saw, as it does not use regularly shaped edges (teeth) for cutting.

A chainsaw mill or PortaMill or Logosol sawmill is a type of sawmill incorporating a chainsaw, that is used by one or two operators to mill logs into lumber for use in furniture, construction and other uses. Although often used as a generic term, Alaskan Mill is a registered trademark of Granberg International.

A swingblade sawmill utilizes a single circular sawblade which pivots about a 90 degree point, to saw in both vertical and horizontal planes. The single blade travels horizontally in one direction down the log, and returns in vertical position, thus removing a sawn piece of timber. The swingblade head unit is normally mounted on a moving frame that travels along a track or tracks, up and down a stationary log.

An electric motor brake is a safety feature incorporated into many modern power tools, such as circular saws, drills, and miter saws. Many manufacturers implement this feature into tools specifically with a spinning blade or cutter.

The M. K. Morse Company is a global manufacturer of saw blades and power tool accessories. M. K. Morse sells products in 70 countries.