Ductility refers to the ability of a material to sustain significant plastic deformation before fracture. Plastic deformation is the permanent distortion of a material under applied stress, as opposed to elastic deformation, which is reversible upon removing the stress. Ductility is a critical mechanical performance indicator, particularly in applications that require materials to bend, stretch, or deform in other ways without breaking. The extent of ductility can be quantitatively assessed using the percent elongation at break, given by the equation:

Fracture is the appearance of a crack or complete separation of an object or material into two or more pieces under the action of stress. The fracture of a solid usually occurs due to the development of certain displacement discontinuity surfaces within the solid. If a displacement develops perpendicular to the surface, it is called a normal tensile crack or simply a crack; if a displacement develops tangentially, it is called a shear crack, slip band, or dislocation.

In mechanics, compressive strength is the capacity of a material or structure to withstand loads tending to reduce size (compression). It is opposed to tensile strength which withstands loads tending to elongate, resisting tension. In the study of strength of materials, compressive strength, tensile strength, and shear strength can be analyzed independently.

Fracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics to characterize the material's resistance to fracture.

In materials science, fracture toughness is the critical stress intensity factor of a sharp crack where propagation of the crack suddenly becomes rapid and unlimited. A component's thickness affects the constraint conditions at the tip of a crack with thin components having plane stress conditions and thick components having plane strain conditions. Plane strain conditions give the lowest fracture toughness value which is a material property. The critical value of stress intensity factor in mode I loading measured under plane strain conditions is known as the plane strain fracture toughness, denoted . When a test fails to meet the thickness and other test requirements that are in place to ensure plane strain conditions, the fracture toughness value produced is given the designation . Fracture toughness is a quantitative way of expressing a material's resistance to crack propagation and standard values for a given material are generally available.

Liquid metal embrittlement is a phenomenon of practical importance, where certain ductile metals experience drastic loss in tensile ductility or undergo brittle fracture when exposed to specific liquid metals. Generally, tensile stress, either externally applied or internally present, is needed to induce embrittlement. Exceptions to this rule have been observed, as in the case of aluminium in the presence of liquid gallium. This phenomenon has been studied since the beginning of the 20th century. Many of its phenomenological characteristics are known and several mechanisms have been proposed to explain it. The practical significance of liquid metal embrittlement is revealed by the observation that several steels experience ductility losses and cracking during hot-dip galvanizing or during subsequent fabrication. Cracking can occur catastrophically and very high crack growth rates have been measured.

John W. Hutchinson is the Abbott and James Lawrence Research Professor of Engineering in the School of Engineering and Applied Sciences at Harvard University. He works in the field of solid mechanics concerned with a broad range of problems in structures and engineering materials.

George Rankin Irwin was an American scientist in the field of fracture mechanics and strength of materials. He was internationally known for his study of fracture of materials.

A shear band is a narrow zone of intense shearing strain, usually of plastic nature, developing during severe deformation of ductile materials. As an example, a soil specimen is shown in Fig. 1, after an axialsymmetric compression test. Initially the sample was cylindrical in shape and, since symmetry was tried to be preserved during the test, the cylindrical shape was maintained for a while during the test and the deformation was homogeneous, but at extreme loading two X-shaped shear bands had formed and the subsequent deformation was strongly localized.

Zdeněk Pavel Bažant is McCormick School Professor and Walter P. Murphy Professor of Civil Engineering and Materials Science in the Department of Civil and Environmental Engineering at Northwestern University's Robert R. McCormick School of Engineering and Applied Science.

Material failure theory is an interdisciplinary field of materials science and solid mechanics which attempts to predict the conditions under which solid materials fail under the action of external loads. The failure of a material is usually classified into brittle failure (fracture) or ductile failure (yield). Depending on the conditions most materials can fail in a brittle or ductile manner or both. However, for most practical situations, a material may be classified as either brittle or ductile.

James Robert Rice is an American engineer, scientist, geophysicist, and Mallinckrodt Professor of Engineering Sciences and Geophysics at the Harvard John A. Paulson School of Engineering and Applied Sciences.

A rigid line inclusion, also called stiffener, is a mathematical model used in solid mechanics to describe a narrow hard phase, dispersed within a matrix material. This inclusion is idealised as an infinitely rigid and thin reinforcement, so that it represents a sort of ‘inverse’ crack, from which the nomenclature ‘anticrack’ derives.

In fracture mechanics, a crack growth resistance curve shows the energy required for crack extension as a function of crack length in a given material. For materials that can be modeled with linear elastic fracture mechanics (LEFM), crack extension occurs when the applied energy release rate exceeds the material's resistance to crack extension .

Ramarathnam Narasimhan is an Indian materials engineer and a professor at the Department of Mechanical Engineering of the Indian Institute of Science. He is known for his pioneering researches on fracture mechanics and is an elected fellow of the Indian Academy of Sciences, Indian National Science Academy and the Indian National Academy of Engineering. The Council of Scientific and Industrial Research, the apex agency of the Government of India for scientific research, awarded him the Shanti Swarup Bhatnagar Prize for Science and Technology, one of the highest Indian science awards for his contributions to Engineering Sciences in 1999.

Robert Oliver Ritchie is the H.T. and Jessie Chua Distinguished Professor of Engineering at the University of California, Berkeley and senior faculty scientist at the Lawrence Berkeley National Laboratory.

Striations are marks produced on the fracture surface that show the incremental growth of a fatigue crack. A striation marks the position of the crack tip at the time it was made. The term striation generally refers to ductile striations which are rounded bands on the fracture surface separated by depressions or fissures and can have the same appearance on both sides of the mating surfaces of the fatigue crack. Although some research has suggested that many loading cycles are required to form a single striation, it is now generally thought that each striation is the result of a single loading cycle.

Katherine T. Faber is an American materials scientist and one of the world's foremost experts in ceramic engineering, material strengthening, and ultra-high temperature materials. Faber is the Simon Ramo Professor of Materials Science at the California Institute of Technology (Caltech). She was previously the Walter P. Murphy Professor and department chair of Materials Science and Engineering at the McCormick School of Engineering and Applied Science at Northwestern University.

Emmanuel E. Gdoutos is a Greek academic, Professor Emeritus at the Democritus University of Thrace and Full Member of the Academy of Athens. He has worked in experimental mechanics, fracture mechanics, composite materials, and sandwich structures. His main scientific accomplishments include the solution of many problems of crack growth under combination of opening-mode and sliding-mode loading which were published in his book: “Problems of Mixed-Mode Crack Propagation." His contributions have been widely recognized worldwide through membership and leadership in scientific societies, national academies and honorary diplomas and awards.

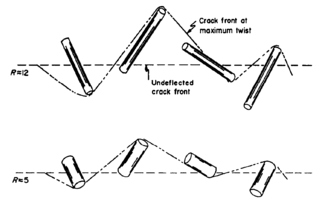

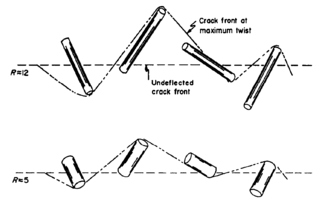

The Faber–Evans model for crack deflection, is a fracture mechanics-based approach to predict the increase in toughness in two-phase ceramic materials due to crack deflection. The effect is named after Katherine Faber and her mentor, Anthony G. Evans, who introduced the model in 1983. The Faber–Evans model is a principal strategy for tempering brittleness and creating effective ductility.