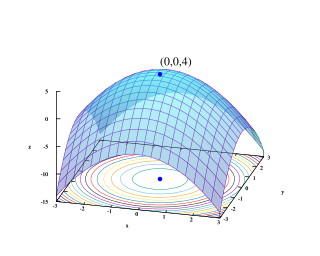

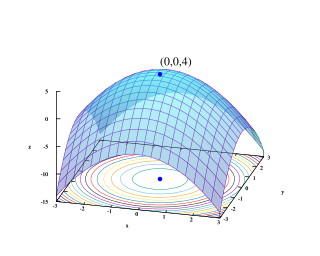

Mathematical optimization or mathematical programming is the selection of a best element, with regard to some criterion, from some set of available alternatives. Optimization problems of sorts arise in all quantitative disciplines from computer science and engineering to operations research and economics, and the development of solution methods has been of interest in mathematics for centuries.

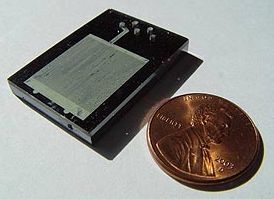

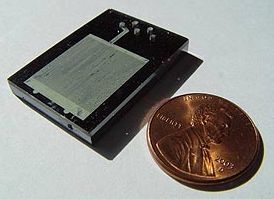

A microreactor or microstructured reactor or microchannel reactor is a device in which chemical reactions take place in a confinement with typical lateral dimensions below 1 mm; the most typical form of such confinement are microchannels. Microreactors are studied in the field of micro process engineering, together with other devices in which physical processes occur. The microreactor is usually a continuous flow reactor. Microreactors offer many advantages over conventional scale reactors, including vast improvements in energy efficiency, reaction speed and yield, safety, reliability, scalability, on-site/on-demand production, and a much finer degree of process control.

Model predictive control (MPC) is an advanced method of process control that is used to control a process while satisfying a set of constraints. It has been in use in the process industries in chemical plants and oil refineries since the 1980s. In recent years it has also been used in power system balancing models and in power electronics. Model predictive controllers rely on dynamic models of the process, most often linear empirical models obtained by system identification. The main advantage of MPC is the fact that it allows the current timeslot to be optimized, while keeping future timeslots in account. This is achieved by optimizing a finite time-horizon, but only implementing the current timeslot and then optimizing again, repeatedly, thus differing from a linear–quadratic regulator (LQR). Also MPC has the ability to anticipate future events and can take control actions accordingly. PID controllers do not have this predictive ability. MPC is nearly universally implemented as a digital control, although there is research into achieving faster response times with specially designed analog circuitry.

A chemical reactor is an enclosed volume in which a chemical reaction takes place. In chemical engineering, it is generally understood to be a process vessel used to carry out a chemical reaction, which is one of the classic unit operations in chemical process analysis. The design of a chemical reactor deals with multiple aspects of chemical engineering. Chemical engineers design reactors to maximize net present value for the given reaction. Designers ensure that the reaction proceeds with the highest efficiency towards the desired output product, producing the highest yield of product while requiring the least amount of money to purchase and operate. Normal operating expenses include energy input, energy removal, raw material costs, labor, etc. Energy changes can come in the form of heating or cooling, pumping to increase pressure, frictional pressure loss or agitation.

A chemical plant is an industrial process plant that manufactures chemicals, usually on a large scale. The general objective of a chemical plant is to create new material wealth via the chemical or biological transformation and or separation of materials. Chemical plants use specialized equipment, units, and technology in the manufacturing process. Other kinds of plants, such as polymer, pharmaceutical, food, and some beverage production facilities, power plants, oil refineries or other refineries, natural gas processing and biochemical plants, water and wastewater treatment, and pollution control equipment use many technologies that have similarities to chemical plant technology such as fluid systems and chemical reactor systems. Some would consider an oil refinery or a pharmaceutical or polymer manufacturer to be effectively a chemical plant.

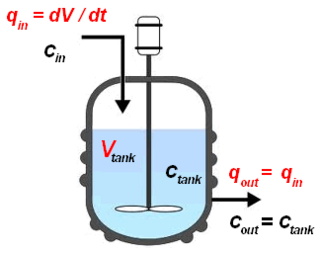

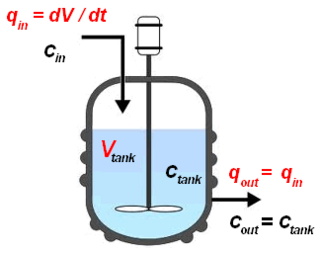

The continuous stirred-tank reactor (CSTR), also known as vat- or backmix reactor, mixed flow reactor (MFR), or a continuous-flow stirred-tank reactor (CFSTR), is a common model for a chemical reactor in chemical engineering and environmental engineering. A CSTR often refers to a model used to estimate the key unit operation variables when using a continuous agitated-tank reactor to reach a specified output. The mathematical model works for all fluids: liquids, gases, and slurries.

A mass balance, also called a material balance, is an application of conservation of mass to the analysis of physical systems. By accounting for material entering and leaving a system, mass flows can be identified which might have been unknown, or difficult to measure without this technique. The exact conservation law used in the analysis of the system depends on the context of the problem, but all revolve around mass conservation, i.e., that matter cannot disappear or be created spontaneously.

A fluidized bed reactor (FBR) is a type of reactor device that can be used to carry out a variety of multiphase chemical reactions. In this type of reactor, a fluid is passed through a solid granular material at high enough speeds to suspend the solid and cause it to behave as though it were a fluid. This process, known as fluidization, imparts many important advantages to an FBR. As a result, FBRs are used for many industrial applications.

A geometric program (GP) is an optimization problem of the form

Willis Harmon Ray is an American chemical engineer, control theorist, applied mathematician, and a Vilas Research emeritus professor at the University of Wisconsin–Madison notable for being the 2000 winner of the prestigious Richard E. Bellman Control Heritage Award and the 2019 winner of the Neal Amundson Award.

Chemical reaction engineering is a specialty in chemical engineering or industrial chemistry dealing with chemical reactors. Frequently the term relates specifically to catalytic reaction systems where either a homogeneous or heterogeneous catalyst is present in the reactor. Sometimes a reactor per se is not present by itself, but rather is integrated into a process, for example in reactive separations vessels, retorts, certain fuel cells, and photocatalytic surfaces. The issue of solvent effects on reaction kinetics is also considered as an integral part.

Design Automation usually refers to electronic design automation, or Design Automation which is a Product Configurator. Extending Computer-Aided Design (CAD), automated design and Computer-Automated Design (CAutoD) are more concerned with a broader range of applications, such as automotive engineering, civil engineering, composite material design, control engineering, dynamic system identification and optimization, financial systems, industrial equipment, mechatronic systems, steel construction, structural optimisation, and the invention of novel systems.

Martin Feinberg is an American chemical engineer and mathematician known for his work in chemical reaction network theory.

Arvind Varma was the R. Games Slayter Distinguished Professor, School of Chemical Engineering at Purdue University. His research interests are in chemical and catalytic reaction engineering, and new energy sources.

This bibliography of Rutherford Aris contains a comprehensive listing of the scientific publications of Aris, including books, journal articles, and contributions to other published material.

In computational engineering, Luus–Jaakola (LJ) denotes a heuristic for global optimization of a real-valued function. In engineering use, LJ is not an algorithm that terminates with an optimal solution; nor is it an iterative method that generates a sequence of points that converges to an optimal solution. However, when applied to a twice continuously differentiable function, the LJ heuristic is a proper iterative method, that generates a sequence that has a convergent subsequence; for this class of problems, Newton's method is recommended and enjoys a quadratic rate of convergence, while no convergence rate analysis has been given for the LJ heuristic. In practice, the LJ heuristic has been recommended for functions that need be neither convex nor differentiable nor locally Lipschitz: The LJ heuristic does not use a gradient or subgradient when one be available, which allows its application to non-differentiable and non-convex problems.

The School of Chemical and Metallurgical Engineering is one of seven schools in the University of the Witwatersrand's Faculty of Engineering and the Built Environment. The School offers 4-year undergraduate degrees and post-graduate degrees in chemical and metallurgical engineering.

The residence time of a fluid parcel is the total time that the parcel has spent inside a control volume. The residence time of a set of parcels is quantified in terms of the frequency distribution of the residence time in the set, which is known as residence time distribution (RTD), or in terms of its average, known as mean residence time.

Design optimization is an engineering design methodology using a mathematical formulation of a design problem to support selection of the optimal design among many alternatives. Design optimization involves the following stages:

- Variables: Describe the design alternatives

- Objective: Elected functional combination of variables

- Constraints: Combination of Variables expressed as equalities or inequalities that must be satisfied for any acceptable design alternative

- Feasibility: Values for set of variables that satisfies all constraints and minimizes/maximizes Objective.

David Glasser is a South African engineer best known for his co-development of attainable region theory and research into improving the efficiency of chemical processes. In 2001 he was the inaugural recipient of the Harry Oppenheimer Fellowship Award. He has also been awarded the Bill-Neale May Gold Medal by the South African Institute of Chemical Engineers, as well as the Science for Society Gold Medal from the Academy of Sciences of South Africa.