Chemical engineering is an engineering field which deals with the study of the operation and design of chemical plants as well as methods of improving production. Chemical engineers develop economical commercial processes to convert raw materials into useful products. Chemical engineering uses principles of chemistry, physics, mathematics, biology, and economics to efficiently use, produce, design, transport and transform energy and materials. The work of chemical engineers can range from the utilization of nanotechnology and nanomaterials in the laboratory to large-scale industrial processes that convert chemicals, raw materials, living cells, microorganisms, and energy into useful forms and products. Chemical engineers are involved in many aspects of plant design and operation, including safety and hazard assessments, process design and analysis, modeling, control engineering, chemical reaction engineering, nuclear engineering, biological engineering, construction specification, and operating instructions.

Systems engineering is an interdisciplinary field of engineering and engineering management that focuses on how to design, integrate, and manage complex systems over their life cycles. At its core, systems engineering utilizes systems thinking principles to organize this body of knowledge. The individual outcome of such efforts, an engineered system, can be defined as a combination of components that work in synergy to collectively perform a useful function.

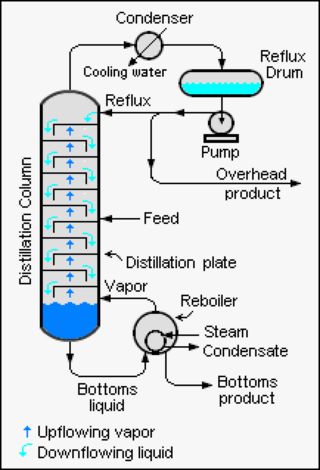

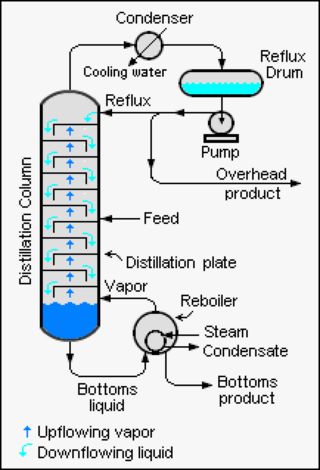

A fractionating column or fractional column is equipment used in the distillation of liquid mixtures to separate the mixture into its component parts, or fractions, based on their differences in volatility. Fractionating columns are used in small-scale laboratory distillations as well as large-scale industrial distillations.

Process engineering is the understanding and application of the fundamental principles and laws of nature that allow humans to transform raw material and energy into products that are useful to society, at an industrial level. By taking advantage of the driving forces of nature such as pressure, temperature and concentration gradients, as well as the law of conservation of mass, process engineers can develop methods to synthesize and purify large quantities of desired chemical products. Process engineering focuses on the design, operation, control, optimization and intensification of chemical, physical, and biological processes. Their work involves analyzing the chemical makeup of various ingredients and determining how they might react with one another. A process engineer can specialize in a number of areas, including the following:

Process Safety Managementof Highly Hazardous Chemicals is a regulation promulgated by the U.S. Occupational Safety and Health Administration (OSHA). It defines and regulates a process safety management (PSM) program for plants using, storing, manufacturing, handling or carrying out on-site movement of hazardous materials above defined amount thresholds. Companies affected by the regulation usually build a compliant process safety management system and integrate it in their safety management system. Non-U.S. companies frequently choose on a voluntary basis to use the OSHA scheme in their business.

A chemical plant is an industrial process plant that manufactures chemicals, usually on a large scale. The general objective of a chemical plant is to create new material wealth via the chemical or biological transformation and or separation of materials. Chemical plants use specialized equipment, units, and technology in the manufacturing process. Other kinds of plants, such as polymer, pharmaceutical, food, and some beverage production facilities, power plants, oil refineries or other refineries, natural gas processing and biochemical plants, water and wastewater treatment, and pollution control equipment use many technologies that have similarities to chemical plant technology such as fluid systems and chemical reactor systems. Some would consider an oil refinery or a pharmaceutical or polymer manufacturer to be effectively a chemical plant.

Effluent is wastewater from sewers or industrial outfalls that flows directly into surface waters, either untreated or after being treated at a facility. The term has slightly different meanings in certain contexts, and may contain various pollutants depending on the source.

Continuous distillation, a form of distillation, is an ongoing separation in which a mixture is continuously fed into the process and separated fractions are removed continuously as output streams. Distillation is the separation or partial separation of a liquid feed mixture into components or fractions by selective boiling and condensation. The process produces at least two output fractions. These fractions include at least one volatile distillate fraction, which has boiled and been separately captured as a vapor condensed to a liquid, and practically always a bottoms fraction, which is the least volatile residue that has not been separately captured as a condensed vapor.

A pilot plant is a pre-commercial production system that employs new production technology and/or produces small volumes of new technology-based products, mainly for the purpose of learning about the new technology. The knowledge obtained is then used for design of full-scale production systems and commercial products, as well as for identification of further research objectives and support of investment decisions. Other (non-technical) purposes include gaining public support for new technologies and questioning government regulations. Pilot plant is a relative term in the sense that pilot plants are typically smaller than full-scale production plants, but are built in a range of sizes. Also, as pilot plants are intended for learning, they typically are more flexible, possibly at the expense of economy. Some pilot plants are built in laboratories using stock lab equipment, while others require substantial engineering efforts, cost millions of dollars, and are custom-assembled and fabricated from process equipment, instrumentation and piping. They can also be used to train personnel for a full-scale plant. Pilot plants tend to be smaller compared to demonstration plants.

In engineering, a process is a series of interrelated tasks that, together, transform inputs into a given output. These tasks may be carried out by people, nature or machines using various resources; an engineering process must be considered in the context of the agents carrying out the tasks and the resource attributes involved. Systems engineering normative documents and those related to Maturity Models are typically based on processes, for example, systems engineering processes of the EIA-632 and processes involved in the Capability Maturity Model Integration (CMMI) institutionalization and improvement approach. Constraints imposed on the tasks and resources required to implement them are essential for executing the tasks mentioned.

A process flow diagram (PFD) is a diagram commonly used in chemical and process engineering to indicate the general flow of plant processes and equipment. The PFD displays the relationship between major equipment of a plant facility and does not show minor details such as piping details and designations. Another commonly used term for a PFD is processflowsheet. It is the key document in process design.

A theoretical plate in many separation processes is a hypothetical zone or stage in which two phases, such as the liquid and vapor phases of a substance, establish an equilibrium with each other. Such equilibrium stages may also be referred to as an equilibrium stage, ideal stage, or a theoretical tray. The performance of many separation processes depends on having series of equilibrium stages and is enhanced by providing more such stages. In other words, having more theoretical plates increases the efficiency of the separation process be it either a distillation, absorption, chromatographic, adsorption or similar process.

Process integration is a term in chemical engineering which has two possible meanings.

- A holistic approach to process design which emphasizes the unity of the process and considers the interactions between different unit operations from the outset, rather than optimising them separately. This can also be called integrated process design or process synthesis. El-Halwagi and Smith (2005) describe the approach well. An important first step is often product design which develops the specification for the product to fulfil its required purpose.

- Pinch analysis, a technique for designing a process to minimise energy consumption and maximise heat recovery, also known as heat integration, energy integration or pinch technology. The technique calculates thermodynamically attainable energy targets for a given process and identifies how to achieve them. A key insight is the pinch temperature, which is the most constrained point in the process. The most detailed explanation of the techniques is by Linnhoff et al. (1982), Shenoy (1995), Kemp (2006) and Kemp and Lim (2020), and it also features strongly in Smith (2005). This definition reflects the fact that the first major success for process integration was the thermal pinch analysis addressing energy problems and pioneered by Linnhoff and co-workers. Later, other pinch analyses were developed for several applications such as mass-exchange networks, water minimization, and material recycle. A very successful extension was "Hydrogen Pinch", which was applied to refinery hydrogen management. This allowed refiners to minimise the capital and operating costs of hydrogen supply to meet ever stricter environmental regulations and also increase hydrotreater yields.

Heinz P. Bloch was an American mechanical engineer with specialization in failure avoidance, machinery maintenance cost reduction and machinery reliability improvement. As of 2020 he has authored over 760 technical papers and conference publications and has written 24 books on practical machinery management and oil mist lubrication. He holds seven U.S. patents relating to high speed machinery.

The COCO Simulator is a free-of-charge, non-commercial, graphical, modular and CAPE-OPEN compliant, steady-state, sequential simulation process modeling environment. It was originally intended as a test environment for CAPE-OPEN modeling tools but now provides free chemical process simulation for students. It is an open flowsheet modeling environment allowing anyone to add new unit operations or thermodynamics packages.

A lamella clarifier or inclined plate settler (IPS) is a type of clarifier designed to remove particulates from liquids.

Reflux is a technique involving the condensation of vapors and the return of this condensate to the system from which it originated. It is used in industrial and laboratory distillations. It is also used in chemistry to supply energy to reactions over a long period of time.

Aspen Plus, Aspen HYSYS, ChemCad and MATLAB, PRO are the commonly used process simulators for modeling, simulation and optimization of a distillation process in the chemical industries. Distillation is the technique of preferential separation of the more volatile components from the less volatile ones in a feed followed by condensation. The vapor produced is richer in the more volatile components. The distribution of the component in the two phase is governed by the vapour-liquid equilibrium relationship. In practice, distillation may be carried out by either two principal methods. The first method is based on the production of vapor boiling the liquid mixture to be separated and condensing the vapors without allowing any liquid to return to the still. There is no reflux. The second method is based on the return of part of the condensate to still under such conditions that this returning liquid is brought into intimate contact with the vapors on their way to condenser.

Techno-economic assessment or techno-economic analysis is a method of analyzing the economic performance of an industrial process, product, or service. The methodology originates from earlier work on combining technical, economic and risk assessments for chemical production processes. It typically uses software modeling to estimate capital cost, operating cost, and revenue based on technical and financial input parameters. One desired outcome is to summarize results in a concise and visually coherent form, using visualization tools such as tornado diagrams and sensitivity analysis graphs.