Related Research Articles

Spinning is a twisting technique to form yarn from fibers. The fiber intended is drawn out, twisted, and wound onto a bobbin. A few popular fibers that are spun into yarn other than cotton, which is the most popular, are viscose, animal fibers such as wool, and synthetic polyester. Originally done by hand using a spindle whorl, starting in the 500s AD the spinning wheel became the predominant spinning tool across Asia and Europe. The spinning jenny and spinning mule, invented in the late 1700s, made mechanical spinning far more efficient than spinning by hand, and especially made cotton manufacturing one of the most important industries of the Industrial Revolution.

The spinning jenny is a multi-spindle spinning frame, and was one of the key developments in the industrialisation of textile manufacturing during the early Industrial Revolution. It was invented in 1764-1765 by James Hargreaves in Stan hill, Oswaldtwistle, Lancashire in England.

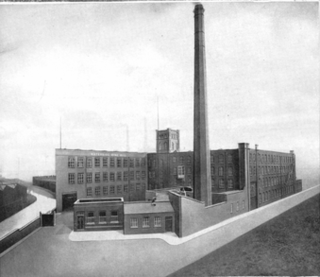

A cotton mill is a building that houses spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

Textile manufacture during the British Industrial Revolution was centred in south Lancashire and the towns on both sides of the Pennines in the United Kingdom. The main drivers of the Industrial Revolution were textile manufacturing, iron founding, steam power, oil drilling, the discovery of electricity and its many industrial applications, the telegraph and many others. Railroads, steamboats, the telegraph and other innovations massively increased worker productivity and raised standards of living by greatly reducing time spent during travel, transportation and communications.

Textile manufacturing is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products.

The spinning mule is a machine used to spin cotton and other fibres. They were used extensively from the late 18th to the early 20th century in the mills of Lancashire and elsewhere. Mules were worked in pairs by a minder, with the help of two boys: the little piecer and the big or side piecer. The carriage carried up to 1,320 spindles and could be 150 feet (46 m) long, and would move forward and back a distance of 5 feet (1.5 m) four times a minute.

William Mason was a master mechanical engineer and builder of textile machinery and railroad steam locomotives. He founded Mason Machine Works of Taunton, Massachusetts. His company was a significant supplier of locomotives and rifles for the Union Army during the American Civil War. The company also later produced printing presses.

Cotton-spinning machinery is machines which process prepared cotton roving into workable yarn or thread. Such machinery can be dated back centuries. During the 18th and 19th centuries, as part of the Industrial Revolution cotton-spinning machinery was developed to bring mass production to the cotton industry. Cotton spinning machinery was installed in large factories, commonly known as cotton mills.

The Lancashire Cotton Corporation was a company set up by the Bank of England in 1929, to rescue the Lancashire spinning industry by means of horizontal rationalisation. In merged 105 companies, ending up in 1950 with 53 operating mills. It was bought up by Courtaulds in August 1964.

Bombay Spinning and Weaving Company was the first cotton mill to be established in Bombay, India, on 7 July 1854 at Tardeo by Cowaszee Nanabhoy Davar (1815–73) and his associates. The company was designed by Sir William Fairbaim. This mill began production on 7 February 1856 under the supervision of British engineers and skilled cotton operatives.

Regent Mill, Failsworth is a Grade II listed former cotton spinning mill in Failsworth, Oldham, Greater Manchester, England. It was built by the Regent Mill Co Ltd. in 1905, and purchased by the Lancashire Cotton Corporation in 1930. It was taken over by the Courtaulds Group in 1964. On ceasing textile production it was occupied by Pifco Ltd, and then by Salton Europe Ltd who now occupy this site. It was driven by an 1800 hp twin tandem compound engine by Buckley & Taylor. It became a ring mill with 60,000 spindles in 1915, all provided by Platt Brothers.

Ring spinning is a spindle-based method of spinning fibres, such as cotton, flax or wool, to make a yarn. The ring frame developed from the throstle frame, which in its turn was a descendant of Arkwright's water frame. Ring spinning is a continuous process, unlike mule spinning which uses an intermittent action. In ring spinning, the roving is first attenuated by using drawing rollers, then spun and wound around a rotating spindle which in its turn is contained within an independently rotating ring flyer. Traditionally ring frames could only be used for the coarser counts, but they could be attended by semi-skilled labour.

Waterside Mill, Ashton-under-Lyne was a combined cotton spinning weaving mill in Whitelands, Ashton-under-Lyne, Greater Manchester, England. It was built as two independent factories. The weaving sheds date from 1857; the four-storey spinning mill dates from 1863. The spinning was taken over by the Lancashire Cotton Corporation in the 1930s. Production finished in 1959. Waterside Mill was converted to electricity around 1911.

The textile industry in India traditionally, after agriculture, is the only industry that has generated huge employment for both skilled and unskilled labour. The textile industry continues to be the second-largest employment generating sector in India. It offers direct employment to over 35 million people in the country. India is the world's second largest exporter of textiles and clothing, and in the fiscal year 2022, the exports stood at US$ 44.4 billion. According to the Ministry of Textiles, the share of textiles in total exports during April–July 2010 was 11.04%. During 2009–2010, the Indian textile industry was pegged at US$55 billion, 64% of which services domestic demand. In 2010, there were 2,500 textile weaving factories and 4,135 textile finishing factories in all of India. According to AT Kearney’s ‘Retail Apparel Index’, India was ranked as the fourth most promising market for apparel retailers in 2009.

Clarence Mill is a five-storey former cotton spinning mill in Bollington, Cheshire, in England. It was built between 1834 and 1877 for the Swindells family of Bollington. It was built alongside the Macclesfield Canal, which opened in 1831.

A doffer is someone who removes "doffs" holding spun fiber such as cotton or wool from a spinning frame and replaces them with empty ones. Historically, spinners, doffers, and sweepers each had separate tasks that were required in the manufacture of spun textiles. From the early days of the industrial revolution, this work, which requires speed and dexterity rather than strength, was often done by children. After World War I, the practice of employing children declined, ending in the United States in 1933. In modern textile mills, doffing machines have now replaced humans.

Jamshedji Nusserwanji Tata was a pioneering Indian industrialist who founded the Tata Group, India's biggest conglomerate company. Named the greatest philanthropist of the century by several polls and ranking lists, he established the city of Jamshedpur. He is regarded as the Father of Indian Industry.

Richard Haworth and Co. was established by Richard Haworth in 1854 as a cotton spinning and manufacturing firm in Cannon Street, Manchester, and Tatton Mill in Salford. Today the company is part of the Ruia Group which comprises a number of companies that import, supply and distribute textiles and hosiery to retailers and hospitality organisations. Richard Haworth Ltd. supplies a range of linens to the hospitality sector.

Tata Textile Mills was a textile mills business of Tata Group, with its head office in Bombay. It consisted of four textile mills; namely, Central India Mills also popularly known as Empress Mills in Nagpur, the Svadeshi Mills in Bombay, the Tata Mills in Bombay, and the Advance Mills in Ahmedabad. For several decades the four mills produced and sold fabrics under the much-reputed brand name of Tata Textiles.

Mungtu Ram Jaipuria was an Indian social worker, industrialist and educationist and the founder of Seth M.R. Jaipuria Schools. The Government of India awarded him Padma Bhushan, the third highest Indian civilian award, in 1971.

References

- 1 2 Chaloner, W. H. (2018-01-12). Industry and Innovation: Selected Essays. Routledge. ISBN 978-1-351-21416-2.

- ↑ The Indian Textile Journal 1854-1954. Indian Textile Journal, Bombay. 1955. p. 8.

- ↑ Maharashtra State Gazetteers: Greater Bombay (2 v.). Director of Government Printing, Stationery and Publications, Maharashtra State. 1960. p. 77.

- ↑ Rungta, Radhe Shyam (1970). The Rise of Business Corporations in India, 1851-1900. CUP Archive. p. 228.

- ↑ Committee, Great Britain Privy Council Judicial; Sutherland (Barrister-at-law), David (1880). Judgments of the Privy Council on Appeals from India, from 1831-1880. Thacker, Spink & Company. p. 327.

- ↑ Māḍagã̄vakara, Govinda Nārāyaṇa (2008). Govind Narayan's Mumbai: An Urban Biography from 1863. Anthem Press. ISBN 978-1-84331-277-2.

- 1 2 Mehta, Makrand (1991). Indian Merchants and Entrepreneurs in Historical Perspective: With Special Reference to Shroffs of Gujarat, 17th to 19th Centuries. Academic Foundation. p. 192. ISBN 978-81-7188-017-1.