Drax power station is a large biomass power station in Drax, North Yorkshire, England, capable of co-firing petroleum coke. It has a 2.6 GW capacity for biomass and had a 1.29 GW capacity for coal that was retired in 2021. Its name comes from the nearby village of Drax. It is situated on the River Ouse between Selby and Goole. Its generating capacity of 3,906 megawatts (MW), which includes the shut down coal units, is the highest of any power station in the United Kingdom, providing about 6% of the United Kingdom's electricity supply.

A fossil fuel power station is a thermal power station which burns a fossil fuel, such as coal or natural gas, to produce electricity. Fossil fuel power stations have machinery to convert the heat energy of combustion into mechanical energy, which then operates an electrical generator. The prime mover may be a steam turbine, a gas turbine or, in small plants, a reciprocating gas engine. All plants use the energy extracted from the expansion of a hot gas, either steam or combustion gases. Although different energy conversion methods exist, all thermal power station conversion methods have their efficiency limited by the Carnot efficiency and therefore produce waste heat.

Coal pollution mitigation, sometimes labeled as clean coal, is a series of systems and technologies that seek to mitigate health and environmental impact of burning coal for energy. Burning coal releases harmful substances, including mercury, lead, sulfur dioxide (SO2), nitrogen oxides (NOx), and carbon dioxide (CO2), contributing to air pollution, acid rain, and greenhouse gas emissions. Methods include flue-gas desulfurization, selective catalytic reduction, electrostatic precipitators, and fly ash reduction focusing on reducing the emissions of these harmful substances. These measures aim to reduce coal's impact on human health and the environment.

Carbon capture and storage (CCS) is a process in which a relatively pure stream of carbon dioxide (CO2) from industrial sources is separated, treated and transported to a long-term storage location. For example, the burning of fossil fuels or biomass results in a stream of CO2 that could be captured and stored by CCS. Usually the CO2 is captured from large point sources, such as a chemical plant or a bioenergy plant, and then stored in a suitable geological formation. The aim is to reduce greenhouse gas emissions and thus mitigate climate change. For example, CCS retrofits for existing power plants can be one of the ways to limit emissions from the electricity sector and meet the Paris Agreement goals.

An integrated gasification combined cycle (IGCC) is a technology using a high pressure gasifier to turn coal and other carbon based fuels into pressurized gas—synthesis gas (syngas). It can then remove impurities from the syngas prior to the electricity generation cycle. Some of these pollutants, such as sulfur, can be turned into re-usable byproducts through the Claus process. This results in lower emissions of sulfur dioxide, particulates, mercury, and in some cases carbon dioxide. With additional process equipment, a water-gas shift reaction can increase gasification efficiency and reduce carbon monoxide emissions by converting it to carbon dioxide. The resulting carbon dioxide from the shift reaction can be separated, compressed, and stored through sequestration. Excess heat from the primary combustion and syngas fired generation is then passed to a steam cycle, similar to a combined cycle gas turbine. This process results in improved thermodynamic efficiency, compared to conventional pulverized coal combustion.

Waste-to-energy (WtE) or energy-from-waste (EfW) is the process of generating energy in the form of electricity and/or heat from the primary treatment of waste, or the processing of waste into a fuel source. WtE is a form of energy recovery. Most WtE processes generate electricity and/or heat directly through combustion, or produce a combustible fuel commodity, such as methane, methanol, ethanol or synthetic fuels, often derived from the product syngas.

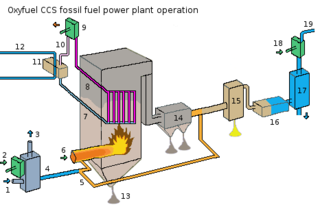

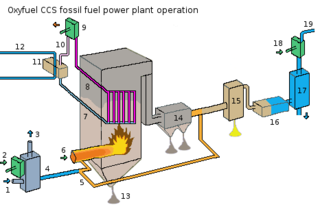

Oxy-fuel combustion is the process of burning a fuel using pure oxygen, or a mixture of oxygen and recirculated flue gas, instead of air. Since the nitrogen component of air is not heated, fuel consumption is reduced, and higher flame temperatures are possible. Historically, the primary use of oxy-fuel combustion has been in welding and cutting of metals, especially steel, since oxy-fuel allows for higher flame temperatures than can be achieved with an air-fuel flame. It has also received a lot of attention in recent decades as a potential carbon capture and storage technology.

A gas-fired power plant, sometimes referred to as gas-fired power station, natural gas power plant, or methane gas power plant, is a thermal power station that burns natural gas to generate electricity. Gas-fired power plants generate almost a quarter of world electricity and are significant sources of greenhouse gas emissions. However, they can provide seasonal, dispatchable energy generation to compensate for variable renewable energy deficits, where hydropower or interconnectors are not available. In the early 2020s batteries became competitive with gas peaker plants.

Carbon capture and storage (CCS) is a technology that can capture carbon dioxide CO2 emissions produced from fossil fuels in electricity, industrial processes which prevents CO2 from entering the atmosphere. Carbon capture and storage is also used to sequester CO2 filtered out of natural gas from certain natural gas fields. While typically the CO2 has no value after being stored, Enhanced Oil Recovery uses CO2 to increase yield from declining oil fields.

The milestones for carbon capture and storage show the lack of commercial scale development and implementation of CCS over the years since the first carbon tax was imposed.

Bioenergy with carbon capture and storage (BECCS) is the process of extracting bioenergy from biomass and capturing and storing the carbon, thereby removing it from the atmosphere. BECCS can theoretically be a "negative emissions technology" (NET), although its deployment at the scale considered by many governments and industries can "also pose major economic, technological, and social feasibility challenges; threaten food security and human rights; and risk overstepping multiple planetary boundaries, with potentially irreversible consequences". The carbon in the biomass comes from the greenhouse gas carbon dioxide (CO2) which is extracted from the atmosphere by the biomass when it grows. Energy ("bioenergy") is extracted in useful forms (electricity, heat, biofuels, etc.) as the biomass is utilized through combustion, fermentation, pyrolysis or other conversion methods.

The Kędzierzyn Zero-Emission Power and Chemical Complex was a proposed facility in Kędzierzyn-Koźle, Poland. It was planned to combine the functions of power and heat generation with chemical production and carbon capture and storage. The project was proposed by a consortium of chemicals producers, including Zakłady Azotowe Kędzierzyn and the electricity company Południowy Koncern Energetyczny. The facility would have produced synthesis gas by gasification of hard coal. Gas produced by the plant would have been used for power and heat generation, or for the production of other chemicals.

Boundary Dam Power Station is the largest coal fired station owned by SaskPower, located near Estevan, Saskatchewan, Canada.

Hi-Gen Power was a London-based developer of projects combining underground coal gasification with carbon capture and storage and alkaline fuel cells. It was established in 2009 to commercialize alkaline fuel cells developed by the fuel cell manufacturer AFC Energy. It is affiliated with B9 Gas.

The Kemper Project, also called the Kemper County energy facility or Plant Ratcliffe, is a natural gas-fired electrical generating station currently under construction in Kemper County, Mississippi. Mississippi Power, a subsidiary of Southern Company, began construction of the plant in 2010. The initial, coal-fired project was central to President Obama's Climate Plan, as it was to be based on "clean coal" and was being considered for more support from the Congress and the incoming Trump Administration in late 2016. If it had become operational with coal, the Kemper Project would have been a first-of-its-kind electricity plant to employ gasification and carbon capture technologies at this scale.

Coal gasification is a process whereby a hydrocarbon feedstock (coal) is converted into gaseous components by applying heat under pressure in the presence of steam. Rather than burning, most of the carbon-containing feedstock is broken apart by chemical reactions that produce "syngas." Syngas is primarily hydrogen and carbon monoxide, but the exact composition can vary. In Integrated Gasification Combined Cycle (IGCC) systems, the syngas is cleaned and burned as fuel in a combustion turbine which then drives an electric generator. Exhaust heat from the combustion turbine is recovered and used to create steam for a steam turbine-generator. The use of these two types of turbines in combination is one reason why gasification-based power systems can achieve high power generation efficiencies. Currently, commercially available gasification-based systems can operate at around 40% efficiencies. Syngas, however, emits more greenhouse gases than natural gas, and almost twice as much carbon as a coal plant. Coal gasification is also water-intensive.

The White Rose Carbon Capture and Storage project was a proposed oxy-fuel coal-fired power plant near the Drax power station in North Yorkshire, United Kingdom. It was proposed in 2012 by Capture Power Limited (in partnership with National Grid). This project would have been the first coal-fired power plant to demonstrate the use of oxy-fuel technology for low-carbon electricity at a competitive cost. The proposed 426 MW plant was expected to send 2 Mt CO2/year to an offshore saline aquifer, achieving 90% capture. The Development Consent Order application submitted to the Department of Energy and Climate Change, now Department for Business, Energy and Industrial Strategy, was rejected in April 2016. The rejection was on the basis that the project had no route to funding, following the UK government cancelling a CCS Competition in November 2015.

Carbon storage in the North Sea includes programmes being run by several Northern European countries to capture carbon, and store it under the North Sea in either old oil and gas workings, or within saline aquifers. Whilst there have been some moves to international co-operation, most of the Carbon Capture and Storage (CCS) programmes are governed by the laws of the country that is running them. Because the governments have pledged net zero carbon emissions by 2050, they have to find ways to deal with any remaining CO2 produced, such as by heavy industry. Around 90% of the identified storage geologies for carbon dioxide in Europe are shared between Norway and the United Kingdom; all of the designated sites for storage are located in the North Sea.

The Whitetail Clean Energy is a proposed power station in Wilton, Redcar and Cleveland, England. The generating process of the plant is listed as a "clean energy source", using natural gas and oxygen in a Allam-Fetvedt Cycle to create power. The excess carbon dioxide not used by the co-generation process is intended to be captured and stored under the North Sea, making the plant the first in the United Kingdom to utilise this type of technology, and also using carbon sequestration under the North Sea. The plant is also included in the Net Zero Teesside project. The power plant is proposed to start generating in 2025.