Related Research Articles

Keykode is an Eastman Kodak Company advancement on edge numbers, which are letters, numbers and symbols placed at regular intervals along the edge of 35 mm and 16 mm film to allow for frame-by-frame specific identification. It was introduced in 1990.

35 mm film is a film gauge used in filmmaking, and the film standard. In motion pictures that record on film, 35 mm is the most commonly used gauge. The name of the gauge is not a direct measurement, and refers to the nominal width of the 35 mm format photographic film, which consists of strips 1.377 ± 0.001 inches (34.976 ± 0.025 mm) wide. The standard image exposure length on 35 mm for movies is four perforations per frame along both edges, which results in 16 frames per foot of film.

A barcode or bar code is a method of representing data in a visual, machine-readable form. Initially, barcodes represented data by varying the widths, spacings and sizes of parallel lines. These barcodes, now commonly referred to as linear or one-dimensional (1D), can be scanned by special optical scanners, called barcode readers, of which there are several types. Later, two-dimensional (2D) variants were developed, using rectangles, dots, hexagons and other patterns, called matrix codes or 2D barcodes, although they do not use bars as such. 2D barcodes can be read using purpose-built 2D optical scanners, which exist in a few different forms. 2D barcodes can also be read by a digital camera connected to a microcomputer running software that takes a photographic image of the barcode and analyzes the image to deconstruct and decode the 2D barcode. A mobile device with an inbuilt camera, such as smartphone, can function as the latter type of 2D barcode reader using specialized application software.

DX encoding is an ANSI and I3A standard, originally introduced by Kodak in March 1983, for marking 135 and APS photographic film and film cartridges. It consists of several parts, a latent image DX film edge barcode on the film below the sprocket holes, a code on the cartridge used by automatic cameras, and a barcode on the cartridge read by photo-finishing machines.

Kodachrome is the brand name for a color reversal film introduced by Eastman Kodak in 1935. It was one of the first successful color materials and was used for both cinematography and still photography. For many years, Kodachrome was widely used for professional color photography, especially for images intended for publication in print media.

A barcode reader is an optical scanner that can read printed barcodes, decode the data contained in the barcode to a computer. Like a flatbed scanner, it consists of a light source, a lens and a light sensor for translating optical impulses into electrical signals. Additionally, nearly all barcode readers contain decoder circuitry that can analyse the barcode's image data provided by the sensor and send the barcode's content to the scanner's output port.

An image scanner—often abbreviated to just scanner—is a device that optically scans images, printed text, handwriting or an object and converts it to a digital image. Commonly used in offices are variations of the desktop flatbed scanner where the document is placed on a glass window for scanning. Hand-held scanners, where the device is moved by hand, have evolved from text scanning "wands" to 3D scanners used for industrial design, reverse engineering, test and measurement, orthotics, gaming and other applications. Mechanically driven scanners that move the document are typically used for large-format documents, where a flatbed design would be impractical.

In photography, reversal film or slide film is a type of photographic film that produces a positive image on a transparent base. Instead of negatives and prints, reversal film is processed to produce transparencies or diapositives. Reversal film is produced in various sizes, from 35 mm to roll film to 8×10 inch sheet film.

Optical Mark Recognition (OMR), collects data from people by identifying markings on a paper. OMR works by detecting a reflection or a little amount of light transmission on or through a sheet of paper using a hardware device (scanner).

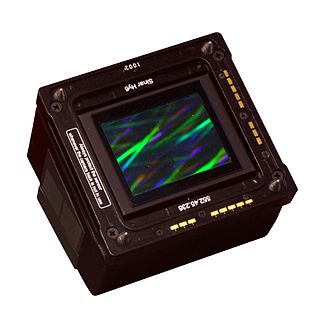

A digital camera back is a device that attaches to the back of a camera in place of the traditional negative film holder and contains an electronic image sensor. This lets cameras that were designed to use film take digital photographs. These camera backs are generally expensive by consumer standards and are primarily built to be attached on medium- and large-format cameras used by professional photographers.

The Cineon System was one of the first computer based digital film systems, created by Kodak in the early 1990s. It was an integrated suite of components consisting a Motion picture film scanner, a film recorder and workstation hardware with software for compositing, visual effects, image restoration and color management.

A film scanner is a device made for scanning photographic film directly into a computer without the use of any intermediate printmaking. It provides several benefits over using a flatbed scanner to scan in a print of any size: the photographer has direct control over cropping and aspect ratio from the original, unmolested image on film; and many film scanners have special software or hardware that removes scratches and film grain and improves color reproduction from film.

Photo CD is a system designed by Kodak for digitizing and saving photos onto a CD. Launched in 1991, the discs were designed to hold nearly 100 high quality images, scanned prints and slides using special proprietary encoding. Photo CDs are defined in the Beige Book and conform to the CD-ROM XA and CD-i Bridge specifications as well. They were intended to play on CD-i players, Photo CD players, and any computer with a suitable software.

Microforms are scaled-down reproductions of documents, typically either films or paper, made for the purposes of transmission, storage, reading, and printing. Microform images are commonly reduced to about 4% or 1⁄25 of the original document size. For special purposes, greater optical reductions may be used.

A motion picture film scanner is a device used in digital filmmaking to scan original film for storage as high-resolution digital intermediate files.

Digital ICE or Digital Image Correction and Enhancement is a set of technologies related to producing an altered image in a variety of frequency spectra. The objective of these technologies is to render an image more usable by Fourier or other filtering techniques. These technologies were most actively advanced in the 1960s and early 1970s in the fields of strategic reconnaissance and medical electronics.

Scanography, more commonly referred to as scanner photography, is the process of capturing digitized images of objects for the purpose of creating printable art using a flatbed "photo" scanner with a CCD array capturing device. Fine art scanography differs from traditional document scanning by using atypical objects, often three-dimensional, as well as from photography, due to the nature of the scanner's operation.

The ColorChecker Color Rendition Chart is a color calibration target consisting of a cardboard-framed arrangement of 24 squares of painted samples. The ColorChecker was introduced in a 1976 paper by McCamy, Marcus, and Davidson in the Journal of Applied Photographic Engineering. The chart’s color patches have spectral reflectances intended to mimic those of natural objects such as human skin, foliage, and flowers, to have consistent color appearance under a variety of lighting conditions, especially as detected by typical color photographic film, and to be stable over time.

Spirit DataCine is a telecine and a motion picture film scanner. This device is able to transfer 16mm and 35mm motion picture film to NTSC or PAL television standards or one of many High-definition television standards. With the data transfer option a Spirit DataCine can output DPX data files. The image pick up device is a solid state charge-coupled device. This eliminated the need for glass vacuum tube CRTs used on older telecines. The units can transfer negative film, primetime, intermediate film and print film, stock. One option is a Super 8 gate for the transfer of Super 8 mm film. With a sound pick up option, optical 16mm and 35mm sound can be reproduced, also 16mm magnetic strip sound. The unit can operate stand alone or be controlled by a scene by scene color corrector. Ken Burns created The Civil War, a short documentary film included in the DVD release, on how he used the Spirit DataCine to transfer and remaster this film. The operator of the unit is called a Colorist or Colorist Assistant. The Spirit DataCine has become the standard for high-end real-time film transfer and scanning. Over 370 units are used in post-production facilities around the world. Most current film productions are transferred on Spirit DataCines for Television, Digital television, Cable television, Satellite television, Direct-to-video, DVD, Blu-ray Disc, pay-per-view, In-flight entertainment, Stock footage, Dailies, Film preservation, digital intermediate and digital cinema. The Spirit DataCine is made by DFT Digital Film Technology GmbH in Darmstadt, Germany.

ibml , founded in 1992, is a privately held information capture company headquartered in Irondale, Alabama, United States. Combining hardware and software products and services, ibml products provide end-to-end scanning and document capture.

References

- 1 2 Kodak (October 2006), Kodak Scanners: Patch Code Information (PDF), Eastman Kodak, A-61599, archived from the original (PDF) on 2016-03-04

- ↑ Choose(4,2)=4!/2!2! = 6

- ↑ Eastman Kodak Company (February 2004), "Patch Setup", Capture Software: User's Guide, pp. 5-1–5-5, A-63054